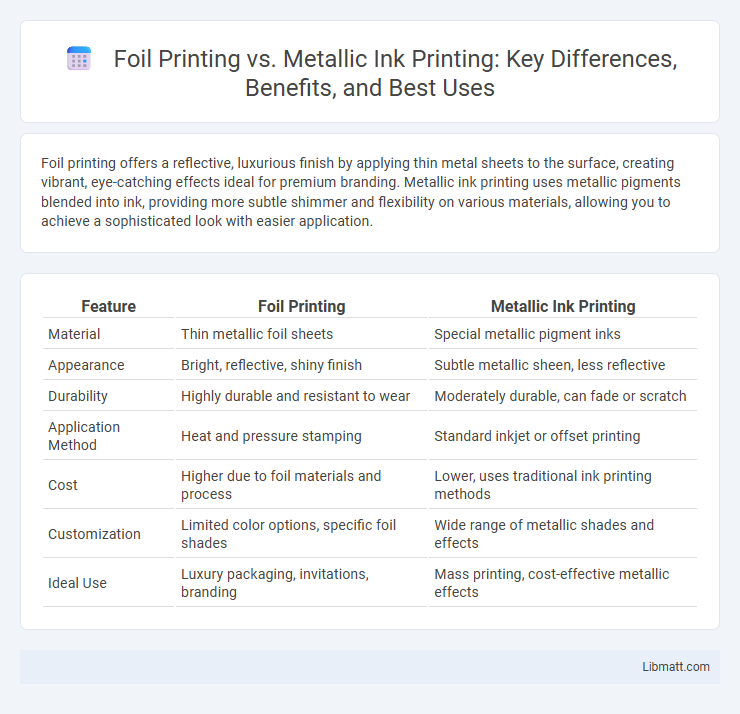

Foil printing offers a reflective, luxurious finish by applying thin metal sheets to the surface, creating vibrant, eye-catching effects ideal for premium branding. Metallic ink printing uses metallic pigments blended into ink, providing more subtle shimmer and flexibility on various materials, allowing you to achieve a sophisticated look with easier application.

Table of Comparison

| Feature | Foil Printing | Metallic Ink Printing |

|---|---|---|

| Material | Thin metallic foil sheets | Special metallic pigment inks |

| Appearance | Bright, reflective, shiny finish | Subtle metallic sheen, less reflective |

| Durability | Highly durable and resistant to wear | Moderately durable, can fade or scratch |

| Application Method | Heat and pressure stamping | Standard inkjet or offset printing |

| Cost | Higher due to foil materials and process | Lower, uses traditional ink printing methods |

| Customization | Limited color options, specific foil shades | Wide range of metallic shades and effects |

| Ideal Use | Luxury packaging, invitations, branding | Mass printing, cost-effective metallic effects |

Introduction to Foil Printing and Metallic Ink Printing

Foil printing utilizes a heat transfer process to apply metallic or pigmented foil onto surfaces, creating a reflective and luxurious finish often used in packaging and invitations. Metallic ink printing involves the use of inks containing metallic particles that produce sheen and shimmer effects directly on the printed material, suitable for detailed graphics and text. Both techniques enhance visual appeal but differ in application methods and textures, with foil printing offering a raised, glossy appearance and metallic inks providing a smooth, luminous finish.

How Foil Printing Works

Foil printing works by applying a thin layer of metallic foil onto a surface using heat and pressure, creating a shiny and reflective finish that enhances design elements with a premium look. This process involves a special adhesive that activates under heat to bond the foil to the paper or material, resulting in vibrant and durable highlights. Your packaging or printed materials gain a luxurious appeal through the precise and intricate effects achievable with foil printing compared to metallic ink printing.

How Metallic Ink Printing Works

Metallic ink printing works by incorporating fine metallic particles or pigments into the ink, which reflect light to create a shiny, metallic finish directly on the substrate. This process requires specialized inks loaded with mica, aluminum, or copper powders, allowing for precise application through traditional printing techniques like offset or screen printing. Unlike foil printing, which relies on heat and pressure to transfer metallic foil onto the surface, metallic ink printing delivers consistent color with a glossy or matte metallic effect through ink absorption.

Visual Effects: Comparing Shine and Finish

Foil printing delivers a highly reflective, mirror-like shine that creates a luxurious and eye-catching finish, ideal for premium packaging and invitations. Metallic ink printing offers a subtler shimmer with a versatile range of colors that provide a smoother, more integrated look on various substrates. Your choice depends on whether you prefer bold, standout shine with foil or a nuanced, metallic glow with ink for your project.

Durability and Longevity of Prints

Foil printing offers superior durability due to its resistance to smudging, fading, and wear, making it ideal for long-lasting designs on packaging and promotional materials. Metallic ink printing, while providing vibrant and reflective finishes, tends to show quicker signs of deterioration under heavy handling or exposure to sunlight. Choosing foil printing ensures enhanced longevity for prints requiring strong visual impact over extended periods.

Suitable Materials and Surfaces

Foil printing excels on smooth, non-porous surfaces such as paper, cardboard, and synthetic materials, providing a reflective, metallic finish that adheres best to coated or lacquered substrates. Metallic ink printing is versatile for porous and uncoated surfaces including textiles, wood, and various plastics, allowing the metallic pigments to be absorbed and maintain flexibility. Choosing between the two depends on the material's texture and intended durability, with foil suited for high-end packaging and metallic ink favored for apparel and flexible materials.

Cost Comparison: Foil vs. Metallic Ink

Foil printing typically incurs higher costs due to the specialized materials and processes involved, making it less budget-friendly for large print runs compared to metallic ink printing. Metallic ink printing offers a more cost-effective solution with easier application and quicker turnaround times, ideal for projects requiring metallic effects on a tighter budget. Evaluating your project's scale and budget will help determine whether the premium finish of foil printing justifies the additional expense over metallic ink alternatives.

Environmental Impact and Sustainability

Foil printing typically involves the use of non-biodegradable plastic films and adhesive, which can contribute to landfill waste and environmental pollution. Metallic ink printing utilizes metal-based pigments mixed with eco-friendlier solvents, resulting in lower environmental toxicity and better recyclability. Choosing metallic ink printing supports sustainable practices by reducing the reliance on synthetic materials and promoting greener disposal methods.

Best Applications for Each Printing Method

Foil printing excels in luxury packaging, wedding invitations, and high-end branding due to its reflective metallic finish and crisp, sharp details. Metallic ink printing is ideal for mass-produced promotional materials, labels, and packaging where cost-effectiveness and a subtle metallic sheen are prioritized. Both methods enhance visual appeal but differ in application based on budget, production scale, and desired finish brightness.

Choosing the Right Printing Technique for Your Project

Foil printing offers a high-gloss, metallic finish by applying heat-activated foil sheets, ideal for luxurious packaging and invitations requiring a premium look. Metallic ink printing uses special pigments to achieve a shiny effect directly on the surface, providing more color variation and flexibility for complex designs at a lower cost. Your choice depends on the desired visual impact, budget, and material compatibility to ensure the best finish and effectiveness for your project.

Foil Printing vs Metallic Ink Printing Infographic

libmatt.com

libmatt.com