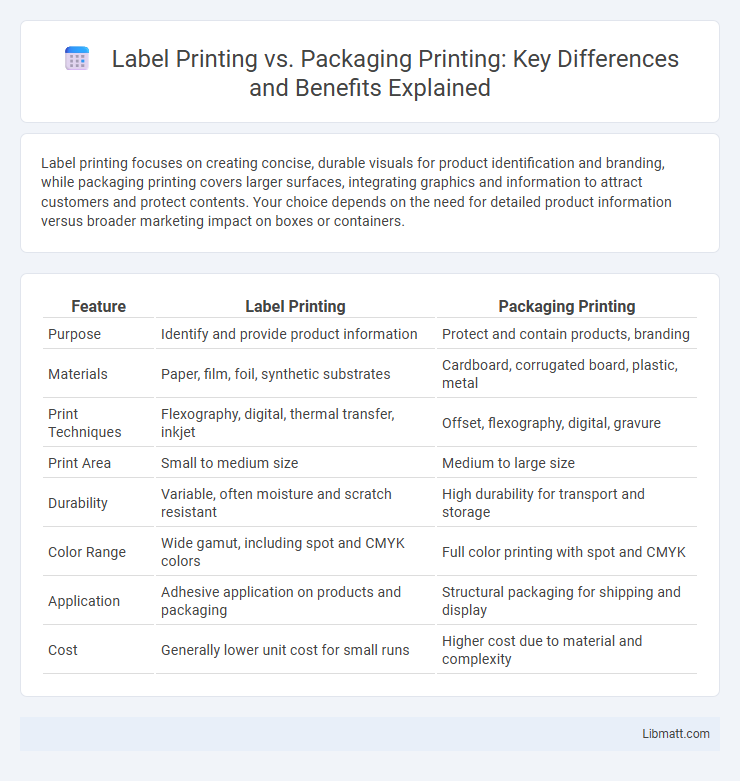

Label printing focuses on creating concise, durable visuals for product identification and branding, while packaging printing covers larger surfaces, integrating graphics and information to attract customers and protect contents. Your choice depends on the need for detailed product information versus broader marketing impact on boxes or containers.

Table of Comparison

| Feature | Label Printing | Packaging Printing |

|---|---|---|

| Purpose | Identify and provide product information | Protect and contain products, branding |

| Materials | Paper, film, foil, synthetic substrates | Cardboard, corrugated board, plastic, metal |

| Print Techniques | Flexography, digital, thermal transfer, inkjet | Offset, flexography, digital, gravure |

| Print Area | Small to medium size | Medium to large size |

| Durability | Variable, often moisture and scratch resistant | High durability for transport and storage |

| Color Range | Wide gamut, including spot and CMYK colors | Full color printing with spot and CMYK |

| Application | Adhesive application on products and packaging | Structural packaging for shipping and display |

| Cost | Generally lower unit cost for small runs | Higher cost due to material and complexity |

Understanding Label Printing

Label printing involves creating adhesive or non-adhesive labels that provide product information, branding, and regulatory details, often using technologies like digital, flexographic, or thermal transfer printing. This process requires precise color matching and material compatibility to ensure durability and legibility on various surfaces. Compared to packaging printing, label printing demands higher attention to detail for small-scale graphics and variable data printing essential for inventory and traceability.

What is Packaging Printing?

Packaging printing involves the process of applying graphics, text, and branding elements onto the materials used to encase products, such as boxes, wrappers, and cartons. It enhances product appeal, provides important information like expiration dates and barcodes, and ensures durability through specialized inks and finishes that withstand handling and environmental factors. Your choice of packaging printing can impact brand recognition, product protection, and consumer trust significantly.

Key Differences Between Label and Packaging Printing

Label printing involves creating adhesive or non-adhesive labels that provide essential product information, branding, and regulatory details, typically printed on materials like paper or synthetic films. Packaging printing covers a broader scope, including the design and printing of boxes, cartons, and flexible packaging materials that protect and market the product. Your choice depends on whether you need focused product identification or comprehensive packaging aesthetics and structural integrity.

Materials Used in Label Printing

Label printing primarily uses materials like paper, film, and foil, designed for durability and adhesion to various surfaces such as glass, plastic, and metal. Specialized coatings like varnishes and laminates enhance resistance to environmental factors including moisture, UV exposure, and abrasion, ensuring label longevity. Your choice of label material impacts print quality, durability, and the overall effectiveness of branding and product information display.

Materials Used in Packaging Printing

Packaging printing utilizes a diverse range of materials, including corrugated cardboard, flexible plastics, and metal foils, chosen for their durability and ability to protect products during transit. These materials often require specialized inks and coatings to ensure vibrant colors and resistance to moisture, abrasion, and chemicals. Your packaging design benefits from selecting substrates that enhance both functionality and visual appeal, ensuring product integrity and brand recognition.

Printing Technologies: Labels vs Packaging

Label printing primarily utilizes digital, flexographic, and thermal transfer technologies for high-resolution, small-format outputs, while packaging printing often employs offset, gravure, and flexographic methods to handle larger surfaces with complex designs and durability requirements. Digital printing offers quick turnaround and variable data printing ideal for labels, whereas packaging printing demands robust inks and substrates to withstand handling and environmental factors. Your choice between label and packaging printing technologies depends on the product's size, material compatibility, and production volume.

Design Considerations for Labels and Packaging

Design considerations for label printing focus on clarity, durability, and brand visibility, ensuring your label withstands environmental factors while attracting consumer attention with vibrant colors and legible fonts. Packaging printing requires a broader approach, integrating structural design, material compatibility, and graphic elements to protect the product and create an engaging unboxing experience that reflects your brand identity. Both processes demand precise color matching and high-resolution printing to maintain consistency across labels and packaging.

Cost Comparison: Label Printing vs Packaging Printing

Label printing generally incurs lower costs due to smaller material usage and simpler processes compared to packaging printing, which demands higher-grade substrates and more complex production techniques. Your budget can be optimized by choosing label printing for product identification, while packaging printing typically involves higher expenses driven by larger print areas and enhanced durability requirements. Understanding these cost dynamics helps balance quality and expenditure for your branding needs.

Sustainability in Label and Packaging Printing

Sustainability in label and packaging printing centers on reducing environmental impact through the use of eco-friendly materials, such as biodegradable substrates and soy-based inks. Innovations like waterless printing and digital processes minimize waste and energy consumption, promoting greener production cycles. Brands increasingly adopt recyclable and compostable packaging labels to meet consumer demand for sustainable products and comply with environmental regulations.

Choosing the Right Printing Solution for Your Product

Label printing offers precise customization for branding and product information, ideal for small to medium-sized packages requiring detailed, high-quality visuals. Packaging printing encompasses larger-scale applications, providing durability and design flexibility suited for protective boxes, cartons, and shipping materials that enhance product appeal and customer experience. Selecting the right printing solution depends on product type, packaging size, branding requirements, and budget considerations to ensure optimal presentation and functionality.

Label Printing vs Packaging Printing Infographic

libmatt.com

libmatt.com