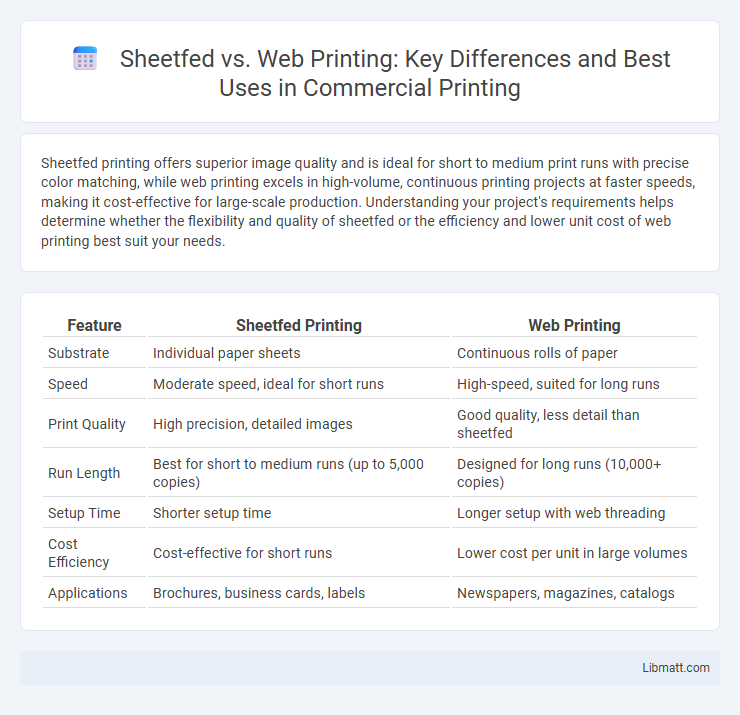

Sheetfed printing offers superior image quality and is ideal for short to medium print runs with precise color matching, while web printing excels in high-volume, continuous printing projects at faster speeds, making it cost-effective for large-scale production. Understanding your project's requirements helps determine whether the flexibility and quality of sheetfed or the efficiency and lower unit cost of web printing best suit your needs.

Table of Comparison

| Feature | Sheetfed Printing | Web Printing |

|---|---|---|

| Substrate | Individual paper sheets | Continuous rolls of paper |

| Speed | Moderate speed, ideal for short runs | High-speed, suited for long runs |

| Print Quality | High precision, detailed images | Good quality, less detail than sheetfed |

| Run Length | Best for short to medium runs (up to 5,000 copies) | Designed for long runs (10,000+ copies) |

| Setup Time | Shorter setup time | Longer setup with web threading |

| Cost Efficiency | Cost-effective for short runs | Lower cost per unit in large volumes |

| Applications | Brochures, business cards, labels | Newspapers, magazines, catalogs |

Introduction to Sheetfed and Web Printing

Sheetfed printing uses individual sheets of paper fed through the press, offering high-quality, precise color reproduction ideal for short to medium print runs. Web printing feeds continuous rolls of paper, enabling faster production speeds and cost-effective large-volume outputs, commonly used for newspapers and catalogs. Your choice depends on print job size, quality requirements, and budget constraints.

Key Differences Between Sheetfed and Web Printing

Sheetfed printing uses individual sheets of paper, offering high-quality, color-precise results ideal for short to medium print runs. Web printing employs continuous rolls of paper, enabling faster output and cost-efficiency for large-volume projects like newspapers and catalogs. Your choice depends on print volume, turnaround time, and material type, with sheetfed excelling in versatility and web printing in speed.

How Sheetfed Printing Works

Sheetfed printing operates by feeding individual sheets of paper through a printing press, allowing precise control over image registration and color consistency. This method is ideal for short to medium print runs, offering high-quality outputs for materials like brochures, business cards, and booklets. Your choice of sheetfed printing ensures crisp detail and vibrant colors tailored to specific print sizes and paper types.

How Web Printing Works

Web printing operates by continuously feeding large rolls of paper through a high-speed press, enabling rapid production of printed materials such as newspapers, magazines, and catalogs. This method uses rotary presses with cylindrical plates that transfer images onto the paper, allowing for efficient handling of long print runs and variable data printing. The continuous feed system reduces setup time and waste compared to sheetfed printing, making web printing ideal for large-volume, time-sensitive print jobs.

Advantages of Sheetfed Printing

Sheetfed printing offers superior print quality and color accuracy, making it ideal for projects that require detailed graphics, such as brochures and high-end marketing materials. It allows for greater flexibility with different paper sizes and types, accommodating short to medium print runs efficiently. Your business can benefit from faster setup times and reduced waste, enhancing cost-effectiveness in customized print jobs.

Benefits of Web Printing

Web printing offers significant advantages such as high-speed production and cost efficiency, making it ideal for large-volume print jobs like magazines, newspapers, and catalogs. This continuous-feed process reduces setup time and waste, enhancing overall productivity and environmental sustainability. You can achieve faster turnaround times and consistent quality on long runs, optimizing your printing operations.

Ideal Applications for Sheetfed Printing

Sheetfed printing excels in producing high-quality, short-to-medium print runs, making it ideal for commercial printing jobs such as brochures, business cards, and posters. It is preferred for applications requiring precise color control, variable data printing, and thicker substrates like cardstock or specialty papers. This method is also suitable for custom packaging and limited edition prints where detail and finish are paramount.

Best Uses for Web Printing

Web printing excels in high-volume production runs such as newspapers, magazines, catalogs, and direct mail campaigns due to its continuous roll-fed process, enabling faster speeds and lower costs per unit. This method suits projects requiring long, uninterrupted print runs with consistent quality, making it ideal for time-sensitive or large-scale commercial printing. Your business benefits from web printing when prioritizing efficiency and economies of scale in mass distribution.

Cost Comparison: Sheetfed vs Web Printing

Sheetfed printing generally incurs higher setup costs per job but offers greater flexibility for short runs and varied print products, making it cost-effective for smaller quantities. Web printing features lower per-unit costs due to continuous roll-fed processes, ideal for high-volume projects with faster turnaround times. Understanding your print volume and budget can help determine whether sheetfed or web printing provides the most economical solution for your needs.

Choosing the Right Printing Method for Your Needs

Sheetfed printing excels in producing high-quality, detailed prints ideal for short to medium runs and customized projects, such as brochures and business cards. Web printing is suited for large-volume, high-speed production, making it cost-effective for newspapers, catalogs, and magazines. Evaluating factors like print volume, turnaround time, and budget helps determine the most efficient method to meet your specific printing requirements.

Sheetfed vs Web Printing Infographic

libmatt.com

libmatt.com