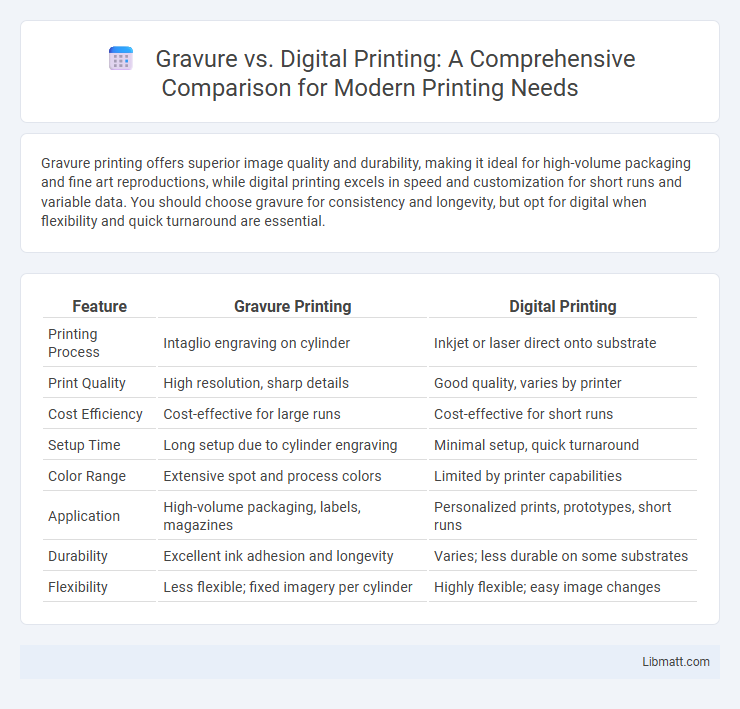

Gravure printing offers superior image quality and durability, making it ideal for high-volume packaging and fine art reproductions, while digital printing excels in speed and customization for short runs and variable data. You should choose gravure for consistency and longevity, but opt for digital when flexibility and quick turnaround are essential.

Table of Comparison

| Feature | Gravure Printing | Digital Printing |

|---|---|---|

| Printing Process | Intaglio engraving on cylinder | Inkjet or laser direct onto substrate |

| Print Quality | High resolution, sharp details | Good quality, varies by printer |

| Cost Efficiency | Cost-effective for large runs | Cost-effective for short runs |

| Setup Time | Long setup due to cylinder engraving | Minimal setup, quick turnaround |

| Color Range | Extensive spot and process colors | Limited by printer capabilities |

| Application | High-volume packaging, labels, magazines | Personalized prints, prototypes, short runs |

| Durability | Excellent ink adhesion and longevity | Varies; less durable on some substrates |

| Flexibility | Less flexible; fixed imagery per cylinder | Highly flexible; easy image changes |

Introduction to Gravure and Digital Printing

Gravure printing uses engraved cylinders to transfer ink onto substrates, offering high-quality and consistent image reproduction for large-volume runs such as magazines and packaging. Digital printing employs electrostatically charged toner or liquid inkjet technology to produce images directly from digital files, enabling quick turnaround and customization with minimal setup costs. Both methods serve distinct applications, with gravure excelling in durability and color richness, and digital printing prized for flexibility and short production runs.

How Gravure Printing Works

Gravure printing operates by engraving images onto a cylindrical plate, where recessed cells hold the ink that transfers directly to the substrate, allowing for high-quality and consistent prints. This method enables precise color control and superior image resolution, making it ideal for large-volume production runs such as magazines, packaging, and wallpaper. The process's ability to maintain sharp detail and vibrant colors even at high speeds distinguishes gravure from other printing techniques like digital printing.

How Digital Printing Works

Digital printing operates by directly transferring digital images onto various substrates using inkjet or laser technology, which allows for precise and high-resolution outputs without the need for printing plates. This method supports variable data printing, facilitating customization and short print runs with faster turnaround times compared to gravure printing. The process utilizes specialized inks and printheads that deposit ink droplets layer by layer, resulting in vibrant and detailed prints suitable for packaging, labels, and promotional materials.

Key Differences between Gravure and Digital Printing

Gravure printing uses engraved cylinders to transfer ink onto substrates, offering superior image quality and durability for high-volume production runs, while digital printing directly applies ink via advanced printers, ideal for shorter runs and rapid turnaround. Gravure excels in consistent color depth and fine detail, making it suitable for packaging and large-scale magazines, whereas digital printing allows for customization and on-demand printing without setup costs. Your choice depends on factors like volume, budget, and design complexity, with gravure favored for bulk, high-fidelity output and digital preferred for flexibility and faster delivery.

Print Quality Comparison

Gravure printing delivers superior print quality with exceptionally fine detail and vibrant color saturation, making it ideal for high-volume applications like packaging and magazines. Digital printing offers flexibility and quick turnaround times but may lack the consistent depth and sharpness found in gravure prints. The choice depends on project requirements, where gravure excels in quality for extensive runs, while digital suits short runs with moderate quality demands.

Cost Analysis: Gravure vs Digital Printing

Gravure printing typically involves higher initial setup costs due to engraved cylinders but offers low per-unit expenses in large-volume runs, making it cost-effective for mass production. Digital printing requires minimal setup and is ideal for short runs or customized jobs, although its per-unit cost remains higher than gravure when scaling up. Cost efficiency between gravure and digital printing depends largely on the print volume and project requirements.

Production Speed and Efficiency

Gravure printing offers high production speed and consistent output, making it ideal for large-volume runs with swift turnaround times. Digital printing excels in efficiency for short runs and quick job changes, eliminating the need for cylinder preparation. Combining gravure's fast mass production with digital's flexibility optimizes overall printing efficiency based on project requirements.

Best Applications for Gravure Printing

Gravure printing excels in high-volume projects requiring consistent, high-quality images, making it ideal for packaging materials, wallpapers, and magazines. Its ability to produce fine details and vibrant colors suits applications like flexible packaging, labels, and decorative films. Your best choice for long runs and superior image reproduction with complex designs is gravure printing.

Ideal Uses for Digital Printing

Digital printing is ideal for short-run projects, personalized prints, and quick turnaround times due to its ability to produce high-quality images without the need for printing plates. This technology excels in producing vibrant colors and detailed images on a variety of materials, making it perfect for marketing materials, small batch packaging, and customized products. Your business benefits from digital printing's flexibility and cost-efficiency when handling variable data or on-demand printing jobs.

Choosing the Right Printing Method for Your Project

Choosing the right printing method depends on project volume, print quality, and budget; gravure printing excels in high-volume, long-run projects with superior image quality and vibrant colors, while digital printing suits short runs, fast turnaround, and variable data printing. Gravure offers consistent, durable prints ideal for packaging and labels, whereas digital printing allows cost-effective customization and quick adaptations without the need for printing plates. Evaluating factors such as print quantity, detail precision, substrate type, and cost efficiency ensures optimal production results.

Gravure vs Digital Printing Infographic

libmatt.com

libmatt.com