Raised ink provides a tactile, three-dimensional texture that enhances the sensory experience and elevates the perceived value of printed materials, while flat ink offers a smooth, uniform finish ideal for vibrant color reproduction and cost-effective printing. Your choice depends on whether you prioritize visual appeal or tactile engagement in your design.

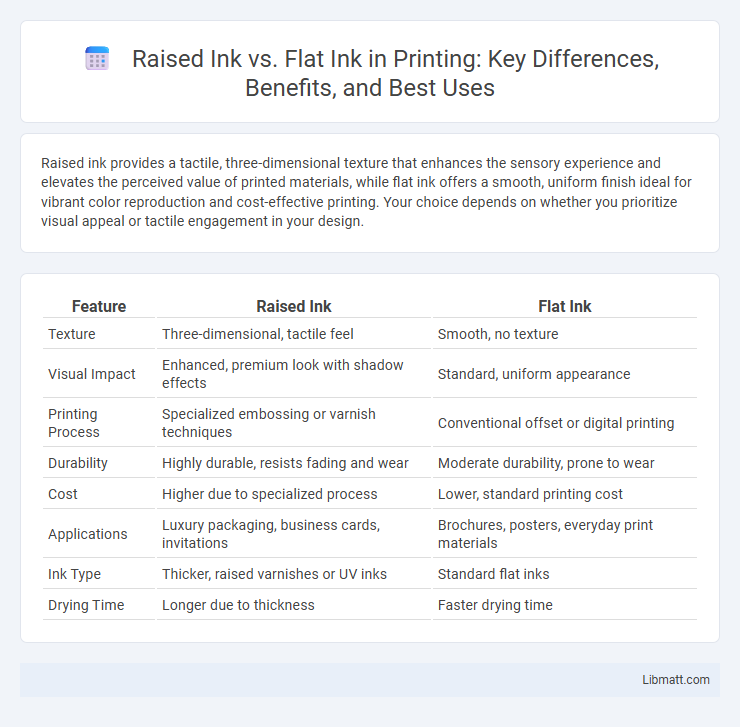

Table of Comparison

| Feature | Raised Ink | Flat Ink |

|---|---|---|

| Texture | Three-dimensional, tactile feel | Smooth, no texture |

| Visual Impact | Enhanced, premium look with shadow effects | Standard, uniform appearance |

| Printing Process | Specialized embossing or varnish techniques | Conventional offset or digital printing |

| Durability | Highly durable, resists fading and wear | Moderate durability, prone to wear |

| Cost | Higher due to specialized process | Lower, standard printing cost |

| Applications | Luxury packaging, business cards, invitations | Brochures, posters, everyday print materials |

| Ink Type | Thicker, raised varnishes or UV inks | Standard flat inks |

| Drying Time | Longer due to thickness | Faster drying time |

Introduction to Raised Ink and Flat Ink

Raised ink, also known as thermographic printing, creates a textured, three-dimensional effect by heating powdered ink, making designs stand out visually and tactilely. Flat ink involves traditional printing methods where ink is applied evenly, resulting in a smooth, two-dimensional surface without texture. Understanding these differences helps you choose the right ink type for your project's desired aesthetic and functional impact.

Defining Raised Ink Printing

Raised ink printing, also known as thermographic printing, creates a tactile, three-dimensional effect by applying a special powder to wet ink, which is then heated to raise the ink surface. Unlike flat ink printing, which produces a smooth, two-dimensional finish, raised ink adds texture and depth, enhancing visual appeal and tactile engagement. This technique is commonly used for business cards, invitations, and packaging to provide a premium, elegant look and feel.

Understanding Flat Ink Printing

Flat ink printing produces a smooth, even surface without any texture or raised elements, making it ideal for detailed images and sharp text on various materials. This printing technique ensures consistent color coverage and clarity, enhancing your designs with a professional, polished look. Unlike raised ink, flat ink is cost-effective and versatile, suitable for everyday printing needs where tactile effects are unnecessary.

Key Differences Between Raised Ink and Flat Ink

Raised ink creates a tactile sensation by adding texture and dimension to printed materials, enhancing both visual appeal and touch experience. Flat ink lies smoothly on the surface, providing a sleek and uniform finish without any raised elements, ideal for clean and professional designs. Your choice between raised ink and flat ink depends on whether you want to emphasize texture and luxury or maintain simplicity and clarity.

Aesthetic Appeal: Texture and Visual Impact

Raised ink creates a tactile texture that enhances the visual impact by adding depth and dimension, making designs feel more luxurious and engaging to touch. Flat ink offers a smooth, uniform surface that allows for crisp, clean lines and vibrant colors, ideal for sharp, detailed images. The choice between raised and flat ink significantly affects the aesthetic appeal, with raised ink providing a premium, textured finish and flat ink delivering precision and color intensity.

Durability and Longevity of Print

Raised ink offers superior durability compared to flat ink, resisting wear and fading even after extensive handling or exposure to environmental elements. The textured surface created by raised ink maintains print clarity over time, making it ideal for tactile applications like business cards and packaging. Flat ink, while cost-effective, tends to degrade faster under friction and UV exposure, leading to diminished print longevity and sharpness.

Cost Comparison: Raised Ink vs Flat Ink

Raised ink printing typically costs more than flat ink due to the specialized equipment and additional production time required to create tactile, embossed effects. Flat ink printing is more economical, leveraging standard printing processes that produce smooth, two-dimensional images without added texture. Your choice between raised and flat ink should consider budget constraints alongside the desired visual and tactile impact.

Best Applications for Raised Ink

Raised ink is ideal for tactile elements such as business cards, invitations, and packaging labels where a premium, textured feel enhances user experience and brand perception. Its three-dimensional quality improves readability and accessibility for visually impaired individuals, making it suitable for braille printing and informational signage. Raised ink also excels in creating striking visual contrasts on marketing materials, brochures, and greeting cards, reinforcing brand identity through sensory engagement.

Ideal Uses for Flat Ink Printing

Flat ink printing excels in producing sharp, vibrant images ideal for high-resolution graphics, detailed photographs, and fine text on materials such as paper, cardstock, and packaging. Its smooth finish supports large-scale print runs in marketing materials like brochures, flyers, and labels, where consistent color saturation and clarity are critical. Flat ink suits projects requiring rapid production without additional texture, ensuring cost-effective, clean, and professional results.

Choosing the Right Ink Method for Your Project

Raised ink creates tactile, dimensional effects that enhance the sensory experience and add a premium touch to invitations, business cards, or packaging. Flat ink offers crisp, vibrant colors and fine details, making it ideal for bulk printing and designs requiring smooth surfaces. Your choice depends on whether you prioritize texture and luxury or color precision and cost-efficiency.

raised ink vs flat ink Infographic

libmatt.com

libmatt.com