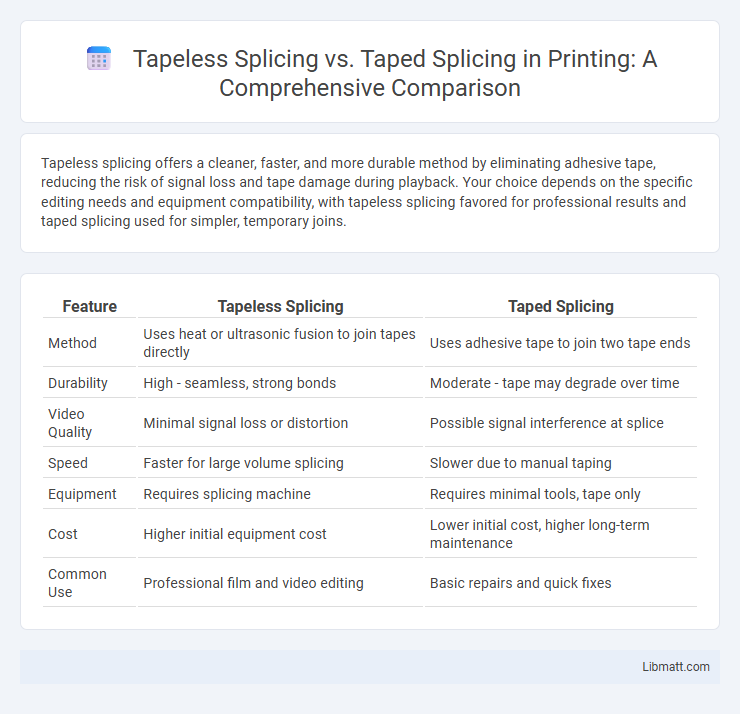

Tapeless splicing offers a cleaner, faster, and more durable method by eliminating adhesive tape, reducing the risk of signal loss and tape damage during playback. Your choice depends on the specific editing needs and equipment compatibility, with tapeless splicing favored for professional results and taped splicing used for simpler, temporary joins.

Table of Comparison

| Feature | Tapeless Splicing | Taped Splicing |

|---|---|---|

| Method | Uses heat or ultrasonic fusion to join tapes directly | Uses adhesive tape to join two tape ends |

| Durability | High - seamless, strong bonds | Moderate - tape may degrade over time |

| Video Quality | Minimal signal loss or distortion | Possible signal interference at splice |

| Speed | Faster for large volume splicing | Slower due to manual taping |

| Equipment | Requires splicing machine | Requires minimal tools, tape only |

| Cost | Higher initial equipment cost | Lower initial cost, higher long-term maintenance |

| Common Use | Professional film and video editing | Basic repairs and quick fixes |

Introduction to Splicing Methods

Tapeless splicing offers a modern approach to fiber optic cable connections by eliminating the need for adhesive tapes, resulting in faster, cleaner, and more reliable joints. In contrast, taped splicing relies on adhesive materials to secure fiber ends, which may introduce signal loss and require additional maintenance. You can optimize network performance and reduce downtime by choosing tapeless splicing for precision and durability in fiber optic installations.

What Is Tapeless Splicing?

Tapeless splicing is a digital editing method that joins video or audio clips without physically cutting or taping the original media, preserving the original quality and enabling more precise, non-destructive edits. Unlike taped splicing, which involves physically cutting and taping film or tape together, tapeless splicing uses software to seamlessly merge files in post-production, reducing the risk of damage and signal degradation. Your workflow benefits from faster turnaround times and improved flexibility when using tapeless splicing techniques in modern digital environments.

What Is Taped Splicing?

Taped splicing involves joining two pieces of film or tape using adhesive tape, providing a quick and reversible connection ideal for temporary edits or repairs. This method is commonly used in analog film editing and magnetic tape applications where preserving the original material is important. Your choice between taped and tapeless splicing depends on the need for durability and the specific media type being handled.

Key Differences Between Tapeless and Taped Splicing

Tapeless splicing uses heat or ultrasonic technology to join optical fibers, offering a cleaner, faster, and more precise connection compared to taped splicing, which relies on adhesive tapes for securing fibers. Taped splicing often results in higher attenuation and less durability, while tapeless splicing ensures lower signal loss and better long-term reliability for your fiber optic networks. This key difference makes tapeless splicing the preferred choice for high-performance telecommunications and data transmission systems.

Advantages of Tapeless Splicing

Tapeless splicing offers significant advantages such as faster processing times and improved efficiency by eliminating the need for adhesive tapes, reducing the risk of contamination and peeling errors. It enhances the durability and reliability of fiber optic connections by providing a clean, consistent splice with minimal signal loss. Your fiber optic maintenance becomes simpler and more cost-effective, minimizing downtime and increasing overall network performance.

Advantages of Taped Splicing

Taped splicing offers superior ease of use and faster application compared to tapeless splicing, making it ideal for quick repairs and routine maintenance. Its enhanced adhesion provides reliable joint strength, reducing downtime and the risk of splice failure in high-stress environments. Your operations benefit from the simplicity and proven performance of taped splicing, especially in industries requiring consistent and durable cable connections.

Common Applications for Each Splicing Method

Tapeless splicing is commonly used in high-speed fiber optic networks and telecommunications where quick, reliable, and clean joints are crucial for minimal signal loss and network uptime. Taped splicing finds frequent application in temporary repairs, outdoor cable installations, and legacy systems where mechanical protection and moisture resistance are priorities. Both methods are essential in different stages of fiber optic cable deployment, with tapeless splicing favored for permanent, high-performance connections and taped splicing preferred for cost-effective, protective, and flexible solutions.

Cost Comparison: Tapeless vs Taped Splicing

Tapeless splicing significantly reduces material costs by eliminating the need for adhesive tape, resulting in lower recurring expenses compared to taped splicing. The initial investment for tapeless splicing equipment can be higher, but its long-term cost efficiency is favorable due to reduced consumable supplies and maintenance needs. Taped splicing incurs ongoing costs associated with tape replacement and potential quality control issues that can increase operational downtime and expenses.

Quality and Reliability Considerations

Tapeless splicing offers superior quality and reliability by eliminating adhesive degradation and tape misalignment, which are common issues in taped splicing. This method ensures consistent optical clarity and strength, reducing signal loss and minimizing maintenance needs. When evaluating your splicing options, tapeless splicing provides a more durable and stable connection for high-performance fiber optic networks.

Choosing the Right Splicing Method for Your Needs

Tapeless splicing offers a cleaner and more efficient option for film and video editors seeking durability and ease of use, eliminating adhesive residue and reducing potential damage to the film stock. Taped splicing provides flexibility and quick adjustments, making it ideal for temporary edits or projects requiring frequent changes, though it may degrade over time and attract dust or debris. Selecting the right method depends on project requirements, the film type, and the desired longevity, with tapeless splicing favored for archival quality and taped splicing suited for rapid, provisional edits.

Tapeless splicing vs taped splicing Infographic

libmatt.com

libmatt.com