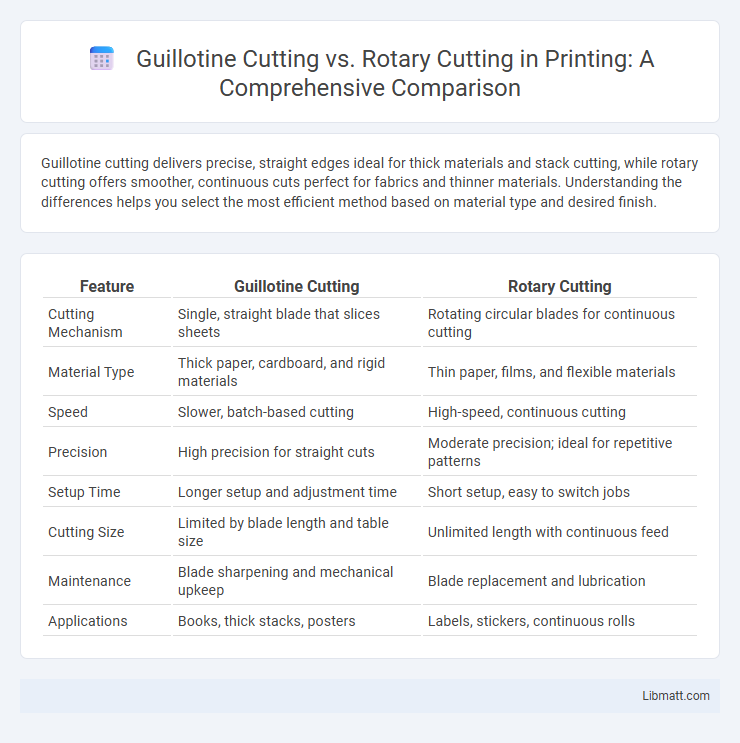

Guillotine cutting delivers precise, straight edges ideal for thick materials and stack cutting, while rotary cutting offers smoother, continuous cuts perfect for fabrics and thinner materials. Understanding the differences helps you select the most efficient method based on material type and desired finish.

Table of Comparison

| Feature | Guillotine Cutting | Rotary Cutting |

|---|---|---|

| Cutting Mechanism | Single, straight blade that slices sheets | Rotating circular blades for continuous cutting |

| Material Type | Thick paper, cardboard, and rigid materials | Thin paper, films, and flexible materials |

| Speed | Slower, batch-based cutting | High-speed, continuous cutting |

| Precision | High precision for straight cuts | Moderate precision; ideal for repetitive patterns |

| Setup Time | Longer setup and adjustment time | Short setup, easy to switch jobs |

| Cutting Size | Limited by blade length and table size | Unlimited length with continuous feed |

| Maintenance | Blade sharpening and mechanical upkeep | Blade replacement and lubrication |

| Applications | Books, thick stacks, posters | Labels, stickers, continuous rolls |

Introduction to Guillotine and Rotary Cutting

Guillotine cutting uses a straight blade that slices through materials in a single downward motion, ideal for precise, clean cuts on paper, cardboard, and thin plastic sheets. Rotary cutting employs a circular blade that rolls across the material, offering smooth, continuous cuts well-suited for fabric, vinyl, and thicker textiles. Both methods optimize cutting efficiency but differ in blade motion and applications based on material type and project requirements.

How Guillotine Cutting Works

Guillotine cutting operates by using a straight blade that moves vertically down onto the material, providing precise, clean, and straight cuts ideal for paper, cardboard, and thin sheets. The material is placed on a flat surface and held firmly in place by a clamp to prevent shifting during the cut, ensuring accuracy. This method is highly effective for high-volume cutting processes where uniformity and exact measurements are critical.

How Rotary Cutting Works

Rotary cutting uses a circular blade that continuously spins and moves along the fabric or paper, allowing for smooth, precise cuts with minimal distortion. The blade's sharp edge slices through multiple layers efficiently, making it suitable for high-volume production and intricate shapes. This technique reduces material waste and increases cutting speed compared to traditional guillotine cutting, which relies on a straight downward blade.

Key Differences Between Guillotine and Rotary Cutting

Guillotine cutting uses a straight blade to cut through multiple layers of material in one swift motion, offering precise, straight-edge results ideal for sheet materials like paper or fabric. Rotary cutting employs a circular blade that rolls over the material, providing smooth, continuous cuts best suited for patterns and curves, often used in textiles and leather. Understanding these key differences helps you choose the right method for your project, balancing speed, precision, and material type.

Material Compatibility and Cutting Capabilities

Guillotine cutting excels at handling thick and rigid materials such as cardboard, foam board, and heavy cardstock with precise straight cuts, making it ideal for large sheets. Rotary cutting offers greater versatility with thinner, flexible fabrics like cotton, silk, and synthetic blends, enabling smooth, curved cuts and detailed shapes. Material compatibility dictates the choice: guillotine cutters prioritize clean, straight edges on dense materials, while rotary cutters accommodate delicate textiles and intricate designs efficiently.

Precision and Accuracy Comparison

Guillotine cutting offers high precision and accuracy by making straight, consistent cuts ideal for thick materials, minimizing material waste. Rotary cutting provides smoother edges and greater accuracy on curved or detailed cuts, perfect for fabrics and flexible materials. Your choice depends on the specific material and cut complexity, with guillotine excelling in straight cuts and rotary in intricate designs.

Efficiency and Speed: Which Method Wins?

Guillotine cutting offers high precision and consistency, making it ideal for thick materials but typically operates at slower speeds due to the mechanical motion required. Rotary cutting excels in speed and efficiency for continuous, high-volume production runs, especially with thinner fabrics or materials, due to its rolling blade mechanism that minimizes downtime. For fast-paced manufacturing environments prioritizing throughput, rotary cutting generally wins, while guillotine cutting is favored for accuracy and handling dense materials.

Safety Considerations for Both Techniques

Guillotine cutting requires strict safety measures due to its exposed blade and potential for severe injury, often necessitating protective guards and emergency stop functions. Rotary cutting, while generally safer because of its enclosed rotary blade design, still demands careful handling to avoid cuts and requires regular maintenance to ensure blade integrity. Both techniques benefit significantly from proper operator training and adherence to safety protocols to minimize risk during operation.

Cost and Maintenance Implications

Guillotine cutting machines generally have higher upfront costs but lower ongoing maintenance expenses due to their straightforward mechanical design. Rotary cutters, while often cheaper initially, require more frequent blade replacements and maintenance to keep precision, increasing long-term costs. Understanding your production volume helps optimize your investment in either guillotine or rotary cutting equipment.

Choosing the Right Cutting Method for Your Needs

Guillotine cutting offers precise, straight cuts ideal for thick materials or high-volume projects, while rotary cutting excels in efficiency and accuracy for intricate, curved designs on thinner materials. Your choice depends on the material type, cutting complexity, and production scale to ensure optimal results. Evaluating these factors helps you select the best cutting method tailored to your specific needs.

Guillotine cutting vs rotary cutting Infographic

libmatt.com

libmatt.com