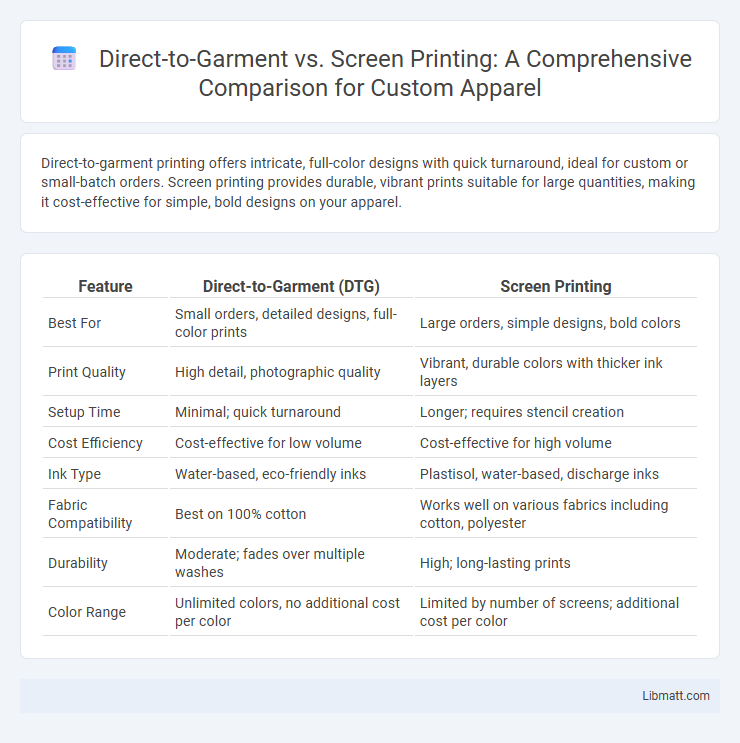

Direct-to-garment printing offers intricate, full-color designs with quick turnaround, ideal for custom or small-batch orders. Screen printing provides durable, vibrant prints suitable for large quantities, making it cost-effective for simple, bold designs on your apparel.

Table of Comparison

| Feature | Direct-to-Garment (DTG) | Screen Printing |

|---|---|---|

| Best For | Small orders, detailed designs, full-color prints | Large orders, simple designs, bold colors |

| Print Quality | High detail, photographic quality | Vibrant, durable colors with thicker ink layers |

| Setup Time | Minimal; quick turnaround | Longer; requires stencil creation |

| Cost Efficiency | Cost-effective for low volume | Cost-effective for high volume |

| Ink Type | Water-based, eco-friendly inks | Plastisol, water-based, discharge inks |

| Fabric Compatibility | Best on 100% cotton | Works well on various fabrics including cotton, polyester |

| Durability | Moderate; fades over multiple washes | High; long-lasting prints |

| Color Range | Unlimited colors, no additional cost per color | Limited by number of screens; additional cost per color |

Introduction to Direct-to-Garment (DTG) and Screen Printing

Direct-to-Garment (DTG) printing involves using specialized inkjet technology to print designs directly onto fabric, offering high-resolution images and vibrant colors ideal for complex or multi-color artwork. Screen printing uses stencils and layers of ink pushed through screens onto garments, excelling in producing durable prints suitable for large batches and simple designs with fewer colors. DTG provides quick turnaround and customization for short runs, while screen printing delivers cost-efficiency and longevity for high-volume orders.

How Direct-to-Garment Printing Works

Direct-to-garment (DTG) printing uses specialized inkjet technology to print designs directly onto fabric fibers with precision and vibrant color. Your artwork is digitally processed and sprayed onto the garment, allowing for high-resolution, full-color prints with fine details and gradients. Unlike screen printing, DTG requires minimal setup, making it ideal for small batches and customized apparel.

Understanding the Screen Printing Process

Screen printing involves pushing ink through a stencil or mesh screen to create vibrant, long-lasting designs on fabric. This method excels in producing bold colors and fine details, particularly on bulk orders due to its cost-effectiveness at scale. Your choice between direct-to-garment and screen printing should consider the screen printing process's efficiency for high volume runs and its durability on various textile types.

Print Quality: DTG vs Screen Printing

Direct-to-garment (DTG) printing excels in producing high-resolution, full-color designs with intricate details and gradients, making it ideal for complex artwork and photographic images. Screen printing offers vibrant, durable prints with solid, bold colors that are perfect for large orders and simpler designs but may struggle with fine detail and color gradients. Your choice between DTG and screen printing should consider the desired print quality, design complexity, and production volume.

Design Flexibility and Color Options

Direct-to-garment (DTG) printing offers exceptional design flexibility with its ability to reproduce intricate details and unlimited color options directly onto fabric, making it ideal for complex, multi-colored artwork. Screen printing, while cost-effective for larger runs, is limited by the number of colors due to separate screens needed for each shade, resulting in simpler designs and fewer color variations. Choosing DTG can provide your custom apparel with vibrant, full-spectrum colors and precise detail that traditional screen printing struggles to achieve.

Production Speed and Order Volume

Direct-to-garment (DTG) printing offers faster production speed for small to medium order volumes, making it ideal for on-demand and custom prints. Screen printing excels in high-volume orders due to its efficient replication process, significantly reducing cost per unit as order size increases. DTG is preferable for limited runs with intricate designs, while screen printing remains the cost-effective choice for bulk production.

Cost Comparison: DTG vs Screen Printing

Direct-to-garment (DTG) printing typically incurs higher costs per unit due to advanced inkjet technology and limited bulk discount opportunities, making it more suitable for small orders or customized designs. Screen printing offers lower costs for large runs because setup fees are spread across many items, significantly reducing the price per garment when you order in bulk. Your decision should factor in order size and design complexity, as DTG is cost-effective for low volume, while screen printing excels in high-volume, simple-color designs.

Sustainability and Environmental Impact

Direct-to-garment (DTG) printing uses water-based inks and produces less waste compared to screen printing, which relies on chemical-intensive processes and generates significant water pollution from ink cleanup. Your choice of DTG supports reduced environmental impact by minimizing water consumption and hazardous chemical discharge. Screen printing's higher energy usage and excess ink waste make DTG the more sustainable option for eco-conscious apparel printing.

Best Use Cases for DTG and Screen Printing

Direct-to-garment (DTG) printing excels in producing highly detailed, full-color designs on small runs or custom orders, making it ideal for personalized apparel and short production deadlines. Screen printing offers durability and vibrant colors best suited for large volume orders and simple, bold graphics like logos or promotional merchandise. Your choice depends on whether you need quick turnaround and intricate designs (DTG) or cost-effective, long-lasting prints for bulk orders (screen printing).

Choosing the Right Printing Method for Your Business

Choosing the right printing method for your business depends on factors like order volume, design complexity, and budget. Direct-to-garment (DTG) excels in producing detailed, full-color prints in small batches with quick turnaround times, making it ideal for custom or on-demand orders. Screen printing offers cost efficiency and durability for large volume orders with simpler designs, providing vibrant colors and long-lasting prints.

Direct-to-garment vs screen printing Infographic

libmatt.com

libmatt.com