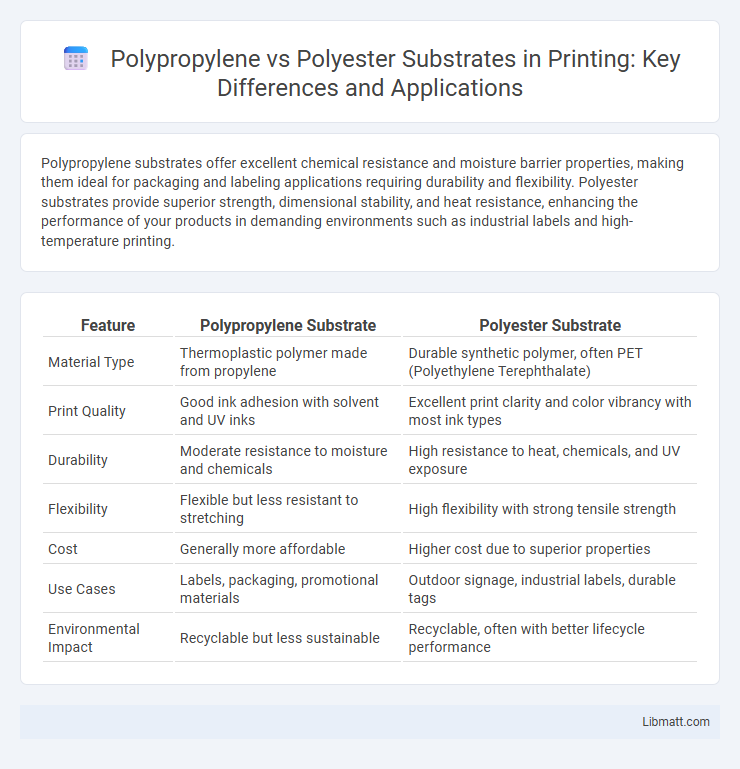

Polypropylene substrates offer excellent chemical resistance and moisture barrier properties, making them ideal for packaging and labeling applications requiring durability and flexibility. Polyester substrates provide superior strength, dimensional stability, and heat resistance, enhancing the performance of your products in demanding environments such as industrial labels and high-temperature printing.

Table of Comparison

| Feature | Polypropylene Substrate | Polyester Substrate |

|---|---|---|

| Material Type | Thermoplastic polymer made from propylene | Durable synthetic polymer, often PET (Polyethylene Terephthalate) |

| Print Quality | Good ink adhesion with solvent and UV inks | Excellent print clarity and color vibrancy with most ink types |

| Durability | Moderate resistance to moisture and chemicals | High resistance to heat, chemicals, and UV exposure |

| Flexibility | Flexible but less resistant to stretching | High flexibility with strong tensile strength |

| Cost | Generally more affordable | Higher cost due to superior properties |

| Use Cases | Labels, packaging, promotional materials | Outdoor signage, industrial labels, durable tags |

| Environmental Impact | Recyclable but less sustainable | Recyclable, often with better lifecycle performance |

Introduction to Substrate Materials

Polypropylene substrates offer excellent chemical resistance, low moisture absorption, and high impact strength, making them ideal for packaging and labeling applications. Polyester substrates provide superior dimensional stability, high tensile strength, and excellent thermal resistance, commonly used in graphics, electronics, and industrial applications. Both substrates deliver distinct benefits in durability and performance, with polypropylene favored for cost-effectiveness and polyester for long-term robustness.

What is Polypropylene Substrate?

Polypropylene substrate is a lightweight, durable plastic material commonly used in packaging, printing, and labeling applications due to its excellent chemical resistance and moisture barrier properties. It offers superior tear resistance and flexibility compared to polyester substrate, making it ideal for products requiring enhanced durability and versatility. Your choice of polypropylene substrate can improve the longevity and performance of printed materials exposed to harsh environments.

What is Polyester Substrate?

Polyester substrate is a durable synthetic material commonly used in printing and packaging due to its high tensile strength, chemical resistance, and excellent dimensional stability. Unlike polypropylene substrate, polyester offers superior heat resistance and better color retention, making it ideal for long-lasting labels and decals. You can choose polyester substrate for applications requiring enhanced durability and resistance to environmental factors.

Physical Properties Comparison

Polypropylene substrates exhibit higher chemical resistance and lower moisture absorption compared to polyester substrates, making them ideal for applications requiring durability in wet environments. Polyester substrates provide superior tensile strength and thermal stability, maintaining structural integrity under high-temperature conditions up to approximately 150degC. Both materials offer excellent dimensional stability, but polypropylene's lower density results in lighter weight products suitable for flexible packaging and lightweight components.

Chemical Resistance and Durability

Polypropylene substrate exhibits superior chemical resistance, particularly against acids, bases, and solvents, making it ideal for harsh chemical environments. Polyester substrate offers excellent durability and UV resistance, maintaining mechanical strength and color stability over time under outdoor exposure. Both substrates provide strong mechanical properties, but polypropylene typically outperforms polyester in resisting chemical degradation and maintaining integrity in aggressive environments.

Printing Compatibility and Performance

Polypropylene substrates offer excellent chemical resistance and durability, making them ideal for solvent and UV printing methods with vibrant color reproduction and long-lasting adhesion. Polyester substrates provide superior dimensional stability and high-temperature resistance, which enhances ink bonding for thermal transfer and dye-sublimation printing, resulting in sharp, detailed images with minimal smudging. Both substrates support high-quality print performance, but polypropylene excels in flexibility and moisture resistance while polyester outperforms in heat tolerance and dimensional accuracy.

Cost Efficiency and Availability

Polypropylene substrates generally offer superior cost efficiency due to lower raw material and production expenses compared to polyester substrates. Their widespread availability in various thicknesses and grades ensures easy procurement for large-scale applications. Polyester substrates, while slightly more expensive, provide enhanced durability and thermal resistance, making them a preferred choice where higher performance justifies the cost.

Environmental Impact and Sustainability

Polypropylene substrates exhibit lower environmental impact due to their recyclability and resistance to chemical degradation, contributing to reduced landfill waste compared to polyester substrates. Polyester substrates, while durable and widely recyclable, generally require more energy and water during production, leading to higher carbon emissions and ecological strain. Choosing polypropylene substrates enhances sustainability by promoting efficient resource use and minimizing ecological footprints in packaging and manufacturing applications.

Industry Applications: Polypropylene vs Polyester

Polypropylene substrates are widely used in packaging, labeling, and automotive industries due to their excellent chemical resistance and moisture barrier properties. Polyester substrates dominate in electronics, printing, and textiles for their superior dimensional stability, durability, and resistance to UV exposure. Both materials offer specific advantages tailored to industry requirements, with polypropylene preferred for cost-effective, moisture-sensitive applications and polyester chosen for strength and longevity in high-performance environments.

Choosing the Right Substrate for Your Needs

Choosing between polypropylene and polyester substrates depends on your specific requirements for durability, flexibility, and environmental resistance. Polypropylene offers excellent chemical resistance and is lightweight, making it suitable for outdoor applications and packaging, while polyester provides superior strength, dimensional stability, and UV resistance, ideal for high-performance printing and signage. Consider your project's exposure to elements and desired longevity to select the substrate that best meets your needs.

Polypropylene substrate vs polyester substrate Infographic

libmatt.com

libmatt.com