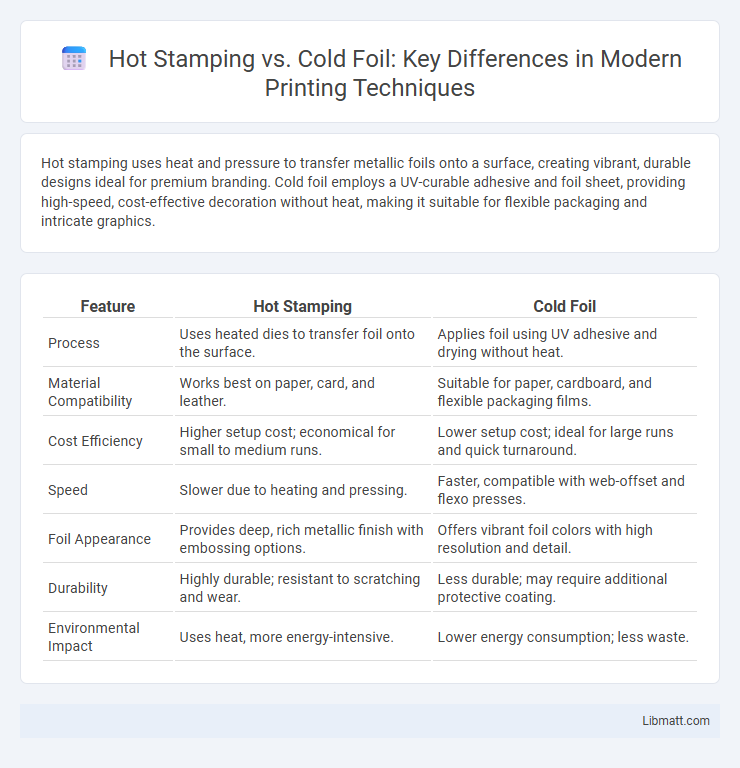

Hot stamping uses heat and pressure to transfer metallic foils onto a surface, creating vibrant, durable designs ideal for premium branding. Cold foil employs a UV-curable adhesive and foil sheet, providing high-speed, cost-effective decoration without heat, making it suitable for flexible packaging and intricate graphics.

Table of Comparison

| Feature | Hot Stamping | Cold Foil |

|---|---|---|

| Process | Uses heated dies to transfer foil onto the surface. | Applies foil using UV adhesive and drying without heat. |

| Material Compatibility | Works best on paper, card, and leather. | Suitable for paper, cardboard, and flexible packaging films. |

| Cost Efficiency | Higher setup cost; economical for small to medium runs. | Lower setup cost; ideal for large runs and quick turnaround. |

| Speed | Slower due to heating and pressing. | Faster, compatible with web-offset and flexo presses. |

| Foil Appearance | Provides deep, rich metallic finish with embossing options. | Offers vibrant foil colors with high resolution and detail. |

| Durability | Highly durable; resistant to scratching and wear. | Less durable; may require additional protective coating. |

| Environmental Impact | Uses heat, more energy-intensive. | Lower energy consumption; less waste. |

Understanding Hot Stamping and Cold Foil

Hot stamping uses heat and pressure to transfer metallic foil onto a surface, producing vibrant, durable finishes ideal for intricate designs and premium packaging. Cold foil applies metallic foil using UV adhesive without heat, enabling faster production on various substrates while maintaining high-quality reflective effects. Both techniques enhance visual appeal but differ in application method, durability, and production speed.

Key Differences Between Hot Stamping and Cold Foil

Hot stamping uses heat and pressure to transfer metallic foil onto a substrate, resulting in a durable, embossed finish, while cold foil employs a UV-curable adhesive and a printing process to apply foil without heat, enabling faster production on lightweight materials. Hot stamping excels in creating vibrant, long-lasting designs on thicker stock such as packaging and book covers; cold foil is preferred for high-speed label printing and flexible packaging due to its cost-effectiveness and suitability for thinner substrates. The choice between hot stamping and cold foil hinges on factors like substrate type, production volume, design complexity, and desired finish durability.

How Hot Stamping Works

Hot stamping works by using heat and pressure to transfer metallic or pigmented foil onto a surface, creating a durable and vibrant finish. A heated die presses the foil against the substrate, causing the foil's adhesive to bond instantly while the carrier film is peeled away. Your project benefits from precise, high-quality decorative effects that cannot be achieved through cold foil techniques.

The Cold Foil Application Process

The cold foil application process involves using a UV-curable adhesive to transfer a metallic foil onto the substrate without heat, allowing for faster production and enhanced design flexibility. This method applies the foil through a flexographic press, where the adhesive is printed on the exact areas to receive the foil, followed by immediate curing with UV light to secure the metallic finish. Cold foil technology provides a cost-effective alternative to hot stamping by enabling high-speed runs and detailed, precise foil application on paper, labels, and packaging materials.

Material Compatibility in Foil Decoration

Hot stamping is compatible with a wide range of materials including paper, leather, plastic, and synthetic substrates, making it ideal for durable and high-quality foil decoration. Cold foil works best on smooth, coated paper and films, as the adhesive bonding requires a flat surface for optimal foil transfer. Material selection impacts foil adhesion, durability, and visual effects, with hot stamping offering broader versatility and cold foil excelling in intricate, high-speed applications on specific substrates.

Design Flexibility: Hot Stamping vs Cold Foil

Hot stamping offers greater design flexibility by allowing intricate patterns and multiple colors with precise registration on various materials, making it ideal for luxurious and detailed finishes. Cold foil, while faster and cost-effective for high-volume runs, provides limited design complexity and is best suited for simpler, large-scale graphics. Your choice depends on whether you prioritize intricate customization or efficient production for your packaging or labeling needs.

Cost Considerations for Each Method

Hot stamping generally incurs higher upfront costs due to the need for metal dies and specialized equipment but can offer lower per-piece expenses for large production runs. Cold foil requires less initial investment with flexible, digitally controlled processes, making it more cost-effective for short runs or customized designs. Your choice depends on the project's scale and budget, balancing die costs against production volume and customization needs.

Durability and Finishing Effects

Hot stamping delivers superior durability through heat and pressure, creating a long-lasting, embossed metallic finish that resists wear and fading. Cold foil offers vibrant, precise color effects with excellent adhesion but may be less resistant to abrasion over time compared to hot stamping. Your choice depends on whether you prioritize lasting durability or intricate, eye-catching finishing effects.

Environmental Impact and Sustainability

Hot stamping typically uses metal foils that may contain non-recyclable materials and requires higher energy consumption due to elevated temperatures, impacting environmental sustainability. Cold foil processes utilize environmentally friendlier adhesives and lower energy usage, producing less waste and enabling easier recycling of substrates. Choosing cold foil over hot stamping can reduce your carbon footprint and support eco-friendly packaging goals.

Choosing the Right Foil Technique for Your Project

Selecting between hot stamping and cold foil depends on your project's durability requirements and design complexity. Hot stamping uses heat and pressure to transfer metallic foils, offering long-lasting, vibrant finishes ideal for high-quality packaging and branding. Cold foil printing, applied during the flexographic printing process, allows faster production and detailed, lightweight metallic effects suited for large runs with intricate graphics.

Hot stamping vs cold foil Infographic

libmatt.com

libmatt.com