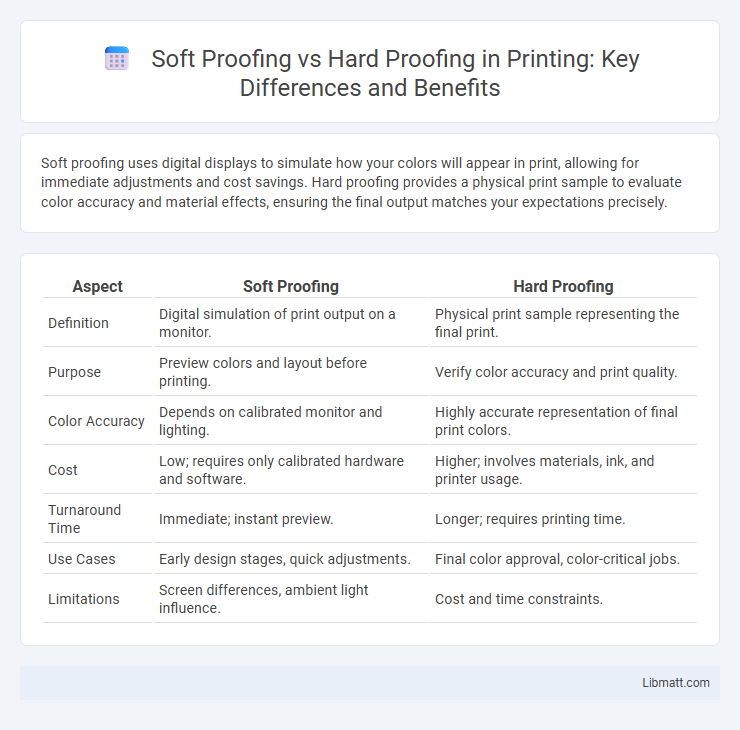

Soft proofing uses digital displays to simulate how your colors will appear in print, allowing for immediate adjustments and cost savings. Hard proofing provides a physical print sample to evaluate color accuracy and material effects, ensuring the final output matches your expectations precisely.

Table of Comparison

| Aspect | Soft Proofing | Hard Proofing |

|---|---|---|

| Definition | Digital simulation of print output on a monitor. | Physical print sample representing the final print. |

| Purpose | Preview colors and layout before printing. | Verify color accuracy and print quality. |

| Color Accuracy | Depends on calibrated monitor and lighting. | Highly accurate representation of final print colors. |

| Cost | Low; requires only calibrated hardware and software. | Higher; involves materials, ink, and printer usage. |

| Turnaround Time | Immediate; instant preview. | Longer; requires printing time. |

| Use Cases | Early design stages, quick adjustments. | Final color approval, color-critical jobs. |

| Limitations | Screen differences, ambient light influence. | Cost and time constraints. |

Introduction to Soft Proofing and Hard Proofing

Soft proofing simulates the appearance of printed materials on a digital screen using color-managed displays to preview how colors will look in the final print. Hard proofing involves producing a physical sample print to evaluate color accuracy, paper texture, and print quality before full production. Both methods are essential in ensuring consistency and minimizing errors in graphic design and printing workflows.

Understanding the Proofing Process in Printing

Soft proofing involves digital simulations of the final print, allowing you to preview color accuracy and layout on screens before production, reducing material waste and saving time. Hard proofing uses physical prints on actual substrates to provide a tactile and precise color representation, essential for detecting printing errors and ensuring final quality. Understanding these proofing methods in printing helps optimize your workflow by balancing cost efficiency with the need for accurate color and detail verification.

Key Differences Between Soft Proofing and Hard Proofing

Soft proofing utilizes digital displays to simulate print colors, enabling real-time adjustments and cost-effective previews of the final output. Hard proofing involves producing a physical print sample using the actual printing process or devices, ensuring accurate color representation and substrate effects. Key differences include medium (digital vs. physical), cost-effectiveness, and precision in color fidelity and material texture representation.

Advantages of Soft Proofing

Soft proofing offers precise color accuracy and real-time adjustments by simulating printed output on calibrated monitors, reducing the need for costly physical prints. It allows designers and clients to review and approve proofs remotely, accelerating the prepress approval process and minimizing production delays. The digital nature of soft proofing enhances sustainability by cutting down on paper waste and lowering overall printing costs.

Advantages of Hard Proofing

Hard proofing offers precise color accuracy and material simulation, allowing you to evaluate the final print quality under actual lighting conditions. It provides a tangible reference that helps identify potential issues such as texture, gloss, and substrate effects, which soft proofing cannot replicate. This method enhances confidence in print production by delivering a realistic representation of the finished product.

Common Challenges in Proofing Methods

Soft proofing often struggles with accurate color representation due to variations in monitor calibration and ambient lighting conditions, which can cause discrepancies between screen display and final print output. Hard proofing faces challenges like higher costs and longer turnaround times, as physical proofs require material and production resources. Your ability to detect subtle color shifts is limited in soft proofing, while hard proofing may not effectively simulate certain digital effects or post-processing adjustments.

When to Use Soft Proofing vs Hard Proofing

Soft proofing is ideal during the early stages of the design process to simulate how colors will appear on different devices or print outputs, enabling quick adjustments without physical samples. Hard proofing is essential before final production to verify color accuracy and print quality on actual substrates, ensuring the final product meets exact standards. Choose soft proofing for efficiency and initial color validation, and hard proofing for precise, tangible proof confirmation.

Tools and Technologies for Effective Proofing

Soft proofing employs color calibrated monitors and specialized software like Adobe Photoshop and X-Rite i1Profiler to simulate print results digitally, enabling quick adjustments and cost savings. Hard proofing relies on physical proofs produced by high-end inkjet printers or contract proofing services that use industry-standard substrates and inks to verify color accuracy and print quality under actual conditions. Combining advanced spectrophotometers for color measurement and color management systems ensures consistency and precision across both proofing methods in professional printing workflows.

Cost Implications of Soft vs Hard Proofing

Soft proofing reduces costs by eliminating the need for physical materials and shipping expenses, making it an efficient choice for budget-conscious projects. Hard proofing incurs higher expenses due to the production of physical samples, including paper, inks, and labor, which can significantly impact overall project budgets. Companies often balance cost implications with quality assurance needs when choosing between soft and hard proofing methods.

Best Practices for Accurate Print Proofing

Soft proofing uses calibrated monitors and color-managed software to simulate final print output, allowing quick adjustments without waste. Hard proofing involves physical prints on proofing devices matching the production press to verify color accuracy under controlled lighting conditions. Combining both ensures precise color matching, minimizes costly errors, and streamlines the print approval process for optimal results.

Soft proofing vs hard proofing Infographic

libmatt.com

libmatt.com