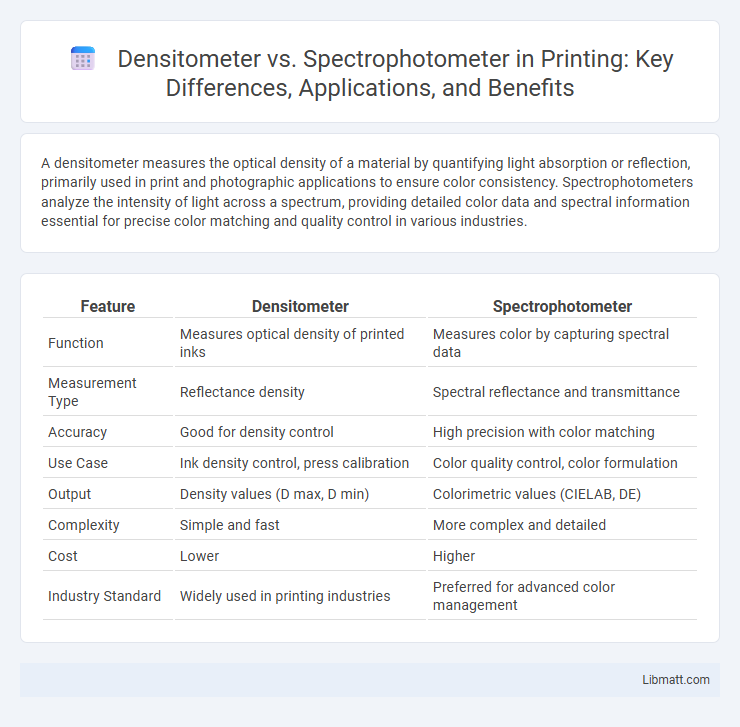

A densitometer measures the optical density of a material by quantifying light absorption or reflection, primarily used in print and photographic applications to ensure color consistency. Spectrophotometers analyze the intensity of light across a spectrum, providing detailed color data and spectral information essential for precise color matching and quality control in various industries.

Table of Comparison

| Feature | Densitometer | Spectrophotometer |

|---|---|---|

| Function | Measures optical density of printed inks | Measures color by capturing spectral data |

| Measurement Type | Reflectance density | Spectral reflectance and transmittance |

| Accuracy | Good for density control | High precision with color matching |

| Use Case | Ink density control, press calibration | Color quality control, color formulation |

| Output | Density values (D max, D min) | Colorimetric values (CIELAB, DE) |

| Complexity | Simple and fast | More complex and detailed |

| Cost | Lower | Higher |

| Industry Standard | Widely used in printing industries | Preferred for advanced color management |

Understanding Densitometers: Key Functions and Applications

Densitometers measure optical density by quantifying the amount of light absorbed or reflected by a material, primarily used in the printing and photographic industries to ensure accurate color reproduction and print quality. These devices are essential for calibrating printers and maintaining consistent color density across production runs, enhancing visual fidelity and product reliability. Key applications include quality control in graphic arts, film production, and textile industries where precise density measurements impact final output.

What Is a Spectrophotometer? Principles and Uses

A spectrophotometer measures the intensity of light absorbed by a sample at specific wavelengths, relying on the principles of light absorption and transmission to quantify chemical concentrations or color properties. It uses a light source, a monochromator to isolate wavelengths, and a detector that records the intensity of transmitted or reflected light, making it ideal for analyzing transparent or colored solutions in laboratories and industries. Your ability to obtain precise absorbance data helps in applications such as quality control, biochemical analysis, and environmental testing.

Densitometer vs Spectrophotometer: Core Differences

Densitometers measure the optical density of photographic or printed materials by quantifying the amount of light absorbed or reflected, primarily used in the printing industry for color control. Spectrophotometers analyze the spectral composition of light, measuring wavelength-specific reflectance or transmittance, enabling precise color matching and characterization across various industries. The core difference lies in densitometers providing density values related to tonal density, while spectrophotometers offer detailed spectral data for comprehensive color analysis.

Measurement Principles: Optical Density vs Spectral Data

Densitometers measure optical density by quantifying the amount of light absorbed or reflected by a sample, primarily evaluating density changes in photographic films or printed materials. Spectrophotometers capture spectral data by measuring the intensity of light across specific wavelengths, enabling precise analysis of color and material composition. The core difference lies in densitometry's focus on overall light absorption, while spectrophotometry provides detailed spectral information for accurate color measurement and material identification.

Accuracy and Precision: Which Device Performs Better?

A spectrophotometer generally offers higher accuracy and precision compared to a densitometer due to its ability to measure a broad spectrum of wavelengths and provide detailed absorbance data. Densitometers primarily measure optical density based on reflected or transmitted light at specific wavelengths, making them less versatile but simpler for routine color density assessments. For applications demanding precise color matching and detailed spectral analysis, spectrophotometers outperform densitometers in delivering consistent and replicable results.

Industry Applications: Printing, Medical, and Beyond

Densitometers are widely used in the printing industry for measuring ink density and ensuring color consistency, while spectrophotometers provide precise color analysis across visible and UV spectra, benefiting medical diagnostics and pharmaceutical quality control. In medical applications, spectrophotometers facilitate accurate quantification of biological samples and assist in tissue analysis, whereas densitometers primarily support radiographic film evaluation. Beyond printing and healthcare, spectrophotometers extend to environmental monitoring and material science, offering versatile spectral data, while densitometers remain crucial for quality control in photographic and industrial processes.

Calibration and Maintenance: Ensuring Reliable Results

Calibration of densitometers involves using standardized step wedges to maintain accurate density measurements, while spectrophotometers require frequent calibration with certified color standards to ensure precise colorimetric data. Regular maintenance for densitometers includes cleaning optical components and verifying sensor alignment, whereas spectrophotometers demand careful calibration of light sources and detector sensitivity. Consistent calibration and proper maintenance of both instruments are critical for delivering reliable, repeatable results in color quality control and print production.

Cost Analysis: Investment and Long-term Value

A densitometer typically involves lower initial investment costs compared to a spectrophotometer, making it a budget-friendly option for simple color density measurements. Spectrophotometers, while more expensive upfront, offer greater accuracy and versatility, which often results in better long-term value for quality control in industries requiring precise color matching. Your decision should balance immediate budget constraints against the need for advanced features and reliable data over time.

Choosing the Right Instrument for Your Needs

Selecting the right instrument depends on your measurement goals: densitometers excel in evaluating optical density and ink film thickness in printing, while spectrophotometers provide comprehensive color analysis through spectral data across various industries. Consider the required accuracy, measurement scope, and application environment; spectrophotometers offer higher precision and versatility for color matching, whereas densitometers are cost-effective and simpler for routine density checks. Prioritize factors such as budget, complexity of color assessment, and calibration needs to ensure optimal performance aligned with your specific workflow.

Future Trends in Color and Density Measurement Technologies

Advancements in color and density measurement technologies are increasingly integrating AI-powered algorithms and machine learning to enhance accuracy and real-time data analysis in densitometers and spectrophotometers. Emerging compact, wireless, and IoT-enabled devices enable seamless integration into automated production lines, improving consistency and efficiency in color quality control. Future trends emphasize multispectral imaging and hyperspectral sensors, offering richer data sets for precise color matching and density evaluations across diverse industries.

Densitometer vs Spectrophotometer Infographic

libmatt.com

libmatt.com