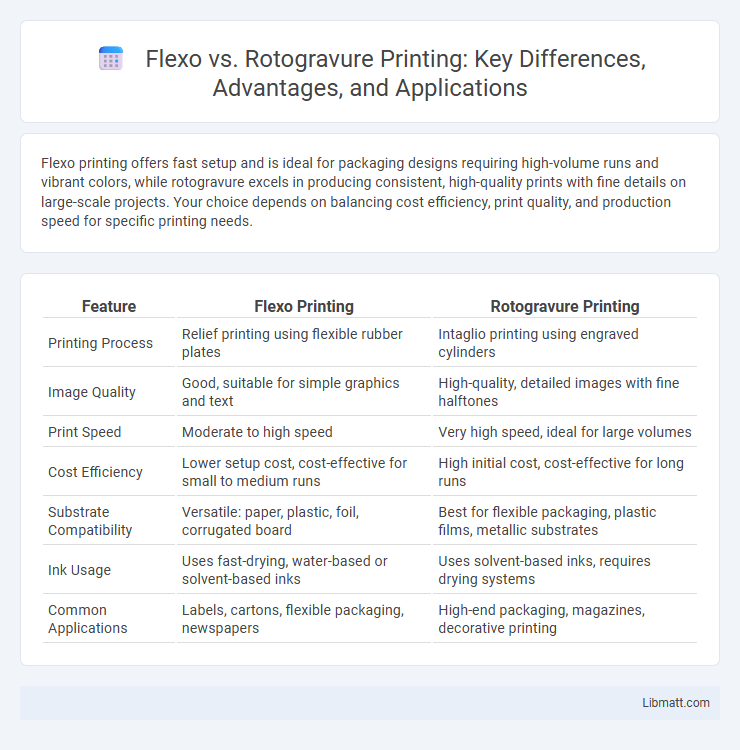

Flexo printing offers fast setup and is ideal for packaging designs requiring high-volume runs and vibrant colors, while rotogravure excels in producing consistent, high-quality prints with fine details on large-scale projects. Your choice depends on balancing cost efficiency, print quality, and production speed for specific printing needs.

Table of Comparison

| Feature | Flexo Printing | Rotogravure Printing |

|---|---|---|

| Printing Process | Relief printing using flexible rubber plates | Intaglio printing using engraved cylinders |

| Image Quality | Good, suitable for simple graphics and text | High-quality, detailed images with fine halftones |

| Print Speed | Moderate to high speed | Very high speed, ideal for large volumes |

| Cost Efficiency | Lower setup cost, cost-effective for small to medium runs | High initial cost, cost-effective for long runs |

| Substrate Compatibility | Versatile: paper, plastic, foil, corrugated board | Best for flexible packaging, plastic films, metallic substrates |

| Ink Usage | Uses fast-drying, water-based or solvent-based inks | Uses solvent-based inks, requires drying systems |

| Common Applications | Labels, cartons, flexible packaging, newspapers | High-end packaging, magazines, decorative printing |

Introduction to Flexo and Rotogravure Printing

Flexo printing uses flexible relief plates and fast-drying inks to produce high-quality images on various substrates, making it ideal for packaging and labels. Rotogravure printing utilizes engraved cylinders and liquid inks to achieve fine detail and consistent print runs, commonly used in magazines, wallpapers, and decorative printing. Both methods offer efficient solutions for large-scale production but differ in technology, cost, and print quality.

Key Differences Between Flexographic and Rotogravure Processes

Flexographic printing uses flexible relief plates to transfer ink, ideal for high-speed, short to medium runs with quick drying times, while rotogravure employs engraved cylinders for consistent, high-quality prints suited to long runs. The key difference lies in image transfer: flexo prints from raised surfaces, offering versatility on various substrates, whereas rotogravure relies on engraved cells that hold ink, delivering finer details and richer color depth. Choosing between flexo and rotogravure depends on your production volume, substrate type, and desired print quality for efficient results.

Substrate Compatibility: Flexo vs Rotogravure

Flexo printing excels in substrate compatibility by handling a wide range of materials, including plastic films, paper, and foil, making it ideal for flexible packaging and labels. Rotogravure offers superior print quality on substrates like coated papers and foils but typically requires more specialized materials to achieve optimal results. Your choice depends on the specific substrate's texture and thickness to ensure high-quality prints with either method.

Print Quality and Image Resolution Comparison

Flexo printing offers moderate print quality with image resolution typically ranging from 72 to 150 lines per inch (LPI), making it ideal for simple graphics and packaging applications. Rotogravure delivers superior print quality with high image resolution up to 300 LPI, allowing for detailed, rich, and continuous-tone images suitable for high-end labels and magazines. Your choice depends on the desired detail level, with rotogravure excelling in image sharpness and color depth compared to the more cost-effective flexo printing.

Cost Efficiency: Setup and Production Costs

Flexo printing offers lower setup costs due to simpler plate creation and faster changeover times, making it cost-efficient for short to medium runs. Rotogravure involves higher initial setup expenses because of engraved cylinders but provides lower per-unit production costs in long print runs, benefiting large-volume projects. Businesses must balance upfront investments against volume requirements to determine the most cost-effective printing method.

Ink Types and Environmental Considerations

Flexo printing uses water-based and UV-cured inks known for faster drying times and reduced volatile organic compound (VOC) emissions, making it more environmentally friendly. Rotogravure employs solvent-based and UV inks that provide superior image quality but typically generate higher VOC emissions, posing greater environmental concerns. Choosing Flexo can minimize your environmental footprint due to its use of eco-friendly inks and efficient drying processes.

Speed and Production Volume Capabilities

Flexo printing offers faster production speeds, making it ideal for high-volume runs with moderate to high flexibility in substrate types. Rotogravure excels in managing extremely high production volumes with consistent quality, especially suited for long-term projects requiring detailed print precision. Your choice between the two depends on the balance between desired speed and volume while maintaining print quality standards.

Typical Applications for Flexo and Rotogravure

Flexo printing is commonly used for packaging materials such as flexible plastics, paper bags, labels, and corrugated containers due to its efficiency in high-speed production and adaptability to various substrates. Rotogravure excels in long-run print jobs like magazines, decorative laminates, and high-quality product packaging, delivering consistent color and fine image detail. Both technologies serve critical roles in packaging and decorative industries but differ in cost-effectiveness and image quality suited to specific application volumes.

Pros and Cons of Flexographic Printing

Flexographic printing offers advantages such as fast drying times, cost-effectiveness for large runs, and versatility in printing on various substrates like plastics, paper, and metallic films. Its lower quality resolution compared to rotogravure and shorter plate lifespan are notable drawbacks, impacting detailed image reproduction and long-term production costs. Flexo's eco-friendly water-based inks and quick setup times make it ideal for packaging applications, but it may not match rotogravure's superior color consistency and fine detail precision.

Pros and Cons of Rotogravure Printing

Rotogravure printing offers exceptional image quality, consistent ink transfer, and the ability to produce long print runs with minimal downtime, making it ideal for high-volume packaging and wallpaper production. However, the process involves high initial cylinder costs and longer setup times, which can be less cost-effective for short runs or frequently changing designs. Your choice should weigh rotogravure's durability and detail against its upfront investment and flexibility limitations compared to other printing methods.

Flexo vs Rotogravure Infographic

libmatt.com

libmatt.com