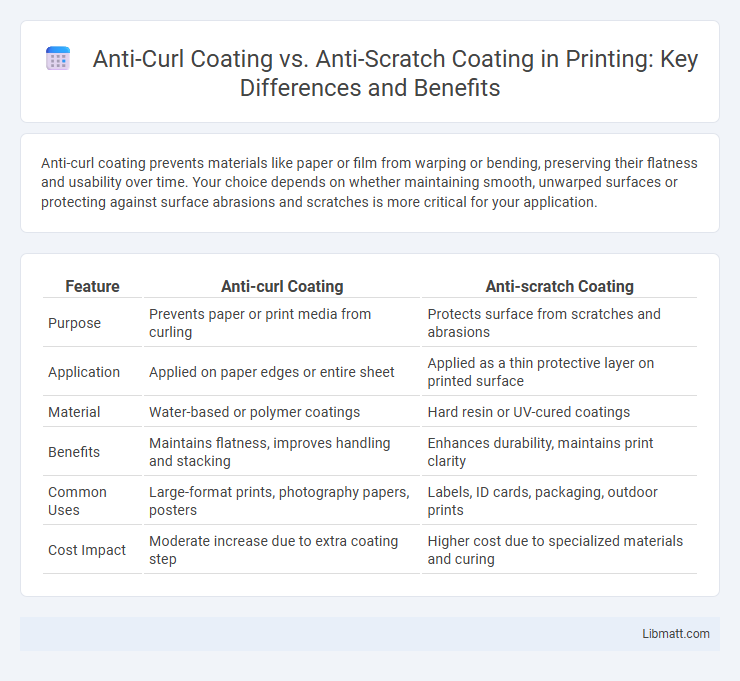

Anti-curl coating prevents materials like paper or film from warping or bending, preserving their flatness and usability over time. Your choice depends on whether maintaining smooth, unwarped surfaces or protecting against surface abrasions and scratches is more critical for your application.

Table of Comparison

| Feature | Anti-curl Coating | Anti-scratch Coating |

|---|---|---|

| Purpose | Prevents paper or print media from curling | Protects surface from scratches and abrasions |

| Application | Applied on paper edges or entire sheet | Applied as a thin protective layer on printed surface |

| Material | Water-based or polymer coatings | Hard resin or UV-cured coatings |

| Benefits | Maintains flatness, improves handling and stacking | Enhances durability, maintains print clarity |

| Common Uses | Large-format prints, photography papers, posters | Labels, ID cards, packaging, outdoor prints |

| Cost Impact | Moderate increase due to extra coating step | Higher cost due to specialized materials and curing |

Introduction to Optical Coatings: Anti-curl vs Anti-scratch

Optical coatings enhance lens durability and performance by targeting different surface issues; anti-curl coatings prevent warping and deformation caused by environmental stress, maintaining lens shape and optical clarity. Anti-scratch coatings, composed of hard, abrasion-resistant materials, protect lenses from physical damage and extend the lifespan of eyewear or optical devices. Selecting between anti-curl and anti-scratch coatings depends on whether the primary concern is structural integrity or scratch resistance in various applications.

What is Anti-curl Coating?

Anti-curl coating is a specialized surface treatment applied to materials like paper or film to prevent edges from curling due to moisture, temperature changes, or handling. This coating maintains the flatness and usability of your product, ensuring it stays smooth and easy to handle during printing or packaging processes. Unlike anti-scratch coatings, which protect surfaces from abrasions and physical damage, anti-curl coatings primarily focus on preserving the structural integrity of sheets and films.

What is Anti-scratch Coating?

Anti-scratch coating is a protective layer applied to surfaces such as lenses, screens, or furniture to increase resistance against scratches and abrasions, preserving clarity and appearance. This coating enhances durability by preventing everyday wear and tear caused by contact with hard or sharp objects. Your devices and eyewear benefit from anti-scratch coatings by maintaining functionality and aesthetic quality over time.

Key Differences Between Anti-curl and Anti-scratch Coatings

Anti-curl coatings primarily prevent the curling or warping of printed materials caused by moisture or heat, maintaining flatness and structural integrity. In contrast, anti-scratch coatings are designed to resist surface abrasions and physical damage, thereby preserving the visual quality and durability of printed surfaces. The key difference lies in their protective functions: anti-curl coatings control dimensional stability, while anti-scratch coatings enhance surface resistance.

Material Composition and Application Methods

Anti-curl coating typically incorporates flexible polymers like polyurethane or silicone to prevent edge lifting and warping in materials such as paper, textiles, or films, applied through roll-to-roll processes or spray coating for uniform elasticity. Anti-scratch coating consists of hard, transparent materials like silica or diamond-like carbon (DLC) applied via methods such as chemical vapor deposition (CVD) or dip coating to enhance surface durability by resisting abrasions. Your choice depends on whether you need protection against physical warping or surface scratches, influencing the selection of coating composition and precise application technique.

Benefits of Using Anti-curl Coating

Anti-curl coating effectively prevents the warping and curling of materials such as paper, film, and synthetic substrates during processing, ensuring dimensional stability and consistent flatness. This coating enhances print quality by maintaining a smooth surface, reducing misfeeds and jams in high-speed printing and converting equipment. Implementing anti-curl coating extends the lifespan of materials and decreases waste, resulting in cost savings and improved efficiency in manufacturing and printing operations.

Advantages of Anti-scratch Coating

Anti-scratch coating significantly enhances the durability and longevity of your device screens or lenses by providing a robust protective layer that resists everyday abrasions and scuffs. This coating maintains clarity and visual quality while reducing the likelihood of permanent damage from sharp objects or rough handling. Compared to anti-curl coatings, anti-scratch coatings offer superior surface protection, ensuring your items remain in pristine condition over extended use.

Ideal Use Cases: Anti-curl vs Anti-scratch

Anti-curl coating is ideal for applications requiring flatness and wrinkle prevention in printed materials, such as posters and photos, ensuring your prints remain smooth and professional-looking. Anti-scratch coating excels in high-contact surfaces prone to abrasion, like smartphone screens and eyewear lenses, providing durable protection against scratches and scuffs. Selecting between these coatings depends on whether your priority is maintaining surface integrity from curling or guarding against physical damage.

Cost Considerations and Longevity

Anti-curl coatings generally offer a more cost-effective solution compared to anti-scratch coatings, making them suitable for budget-conscious applications that require curl resistance. Anti-scratch coatings tend to have higher production costs due to advanced materials and durability enhancements, but they provide superior longevity by protecting surfaces from abrasion and wear over extended use. Evaluating long-term maintenance expenses and replacement frequency is essential when choosing between anti-curl and anti-scratch coatings for optimal cost-efficiency and performance lifespan.

Choosing the Right Coating for Your Needs

Selecting the right coating depends on the primary surface challenge: anti-curl coatings prevent the edges of materials such as paper, film, or composites from warping or curling due to moisture or heat exposure, whereas anti-scratch coatings enhance surface durability by resisting abrasion and surface damage. For products prone to edge deformation in humid or thermal environments, anti-curl coatings maintain flatness and structural integrity. If the application involves frequent handling or contact with abrasive surfaces, prioritizing anti-scratch coatings ensures longevity and preserves aesthetic quality.

Anti-curl Coating vs Anti-scratch Coating Infographic

libmatt.com

libmatt.com