Four-color process printing uses a combination of cyan, magenta, yellow, and black inks to create a wide range of colors through layering, ideal for detailed images and photographs. Spot color printing applies premixed, specific ink colors for consistent, vibrant hues, often chosen for branding elements like logos where color precision is crucial.

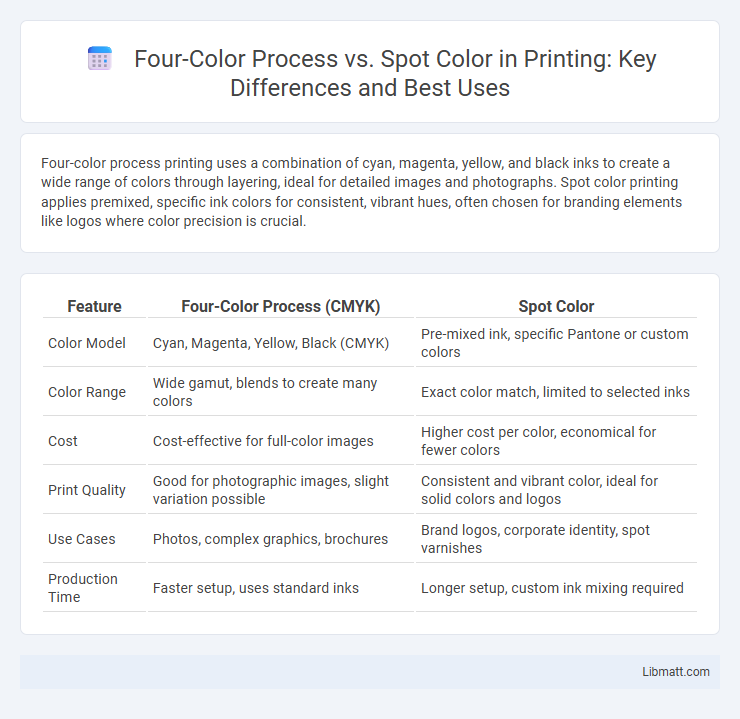

Table of Comparison

| Feature | Four-Color Process (CMYK) | Spot Color |

|---|---|---|

| Color Model | Cyan, Magenta, Yellow, Black (CMYK) | Pre-mixed ink, specific Pantone or custom colors |

| Color Range | Wide gamut, blends to create many colors | Exact color match, limited to selected inks |

| Cost | Cost-effective for full-color images | Higher cost per color, economical for fewer colors |

| Print Quality | Good for photographic images, slight variation possible | Consistent and vibrant color, ideal for solid colors and logos |

| Use Cases | Photos, complex graphics, brochures | Brand logos, corporate identity, spot varnishes |

| Production Time | Faster setup, uses standard inks | Longer setup, custom ink mixing required |

Introduction to Four-Color Process and Spot Color

The four-color process utilizes cyan, magenta, yellow, and black (CMYK) inks to create a wide spectrum of colors through varying ink densities, ideal for detailed and full-color images like photographs. Spot color involves using pre-mixed, specific inks such as Pantone colors to achieve precise, consistent hues that cannot be replicated accurately by CMYK printing, making it essential for brand logos and elements requiring exact color matching. Both methods serve unique purposes in print production, with four-color process offering versatility and spot color providing reliability in color fidelity.

Understanding Four-Color Process Printing

Four-color process printing uses cyan, magenta, yellow, and black (CMYK) inks to create a wide spectrum of colors through layering and blending, ideal for reproducing detailed images and photographs with smooth gradients. Spot color printing utilizes pre-mixed inks for precise color matching, often employed for brand colors, logos, or when exact color consistency is critical across multiple print runs. Understanding the differences is essential for choosing the right method based on project requirements, print quality, and cost efficiency.

What Is Spot Color Printing?

Spot color printing uses pre-mixed inks to produce specific, consistent colors that are not achievable with the four-color process (CMYK) printing, which combines cyan, magenta, yellow, and black inks. Your designs benefit from spot color printing when you require precise color matching, such as brand logos or corporate colors, ensuring vibrancy and accuracy. This method is particularly effective for limited color palettes and can reduce ink usage and costs compared to full-color printing.

Key Differences Between Four-Color and Spot Color

Four-color process uses cyan, magenta, yellow, and black inks to create a wide spectrum of colors through layering, ideal for full-color images and photographs. Spot color employs pre-mixed inks to produce precise, consistent hues, often used for branding or where exact color matching is critical. Key differences lie in color range capability, cost-efficiency for large runs, and color accuracy, with four-color suited for complex images and spot color favored for limited palettes and brand consistency.

Advantages of Four-Color Process

Four-color process printing uses cyan, magenta, yellow, and black inks to reproduce a wide spectrum of colors with high accuracy and detail, making it ideal for photographs and complex artwork. This method offers greater versatility and cost-efficiency for full-color printing jobs compared to spot color, which relies on pre-mixed inks and is limited in color range. Four-color process also streamlines production by reducing setup times and ink inventory, enhancing workflow efficiency for large print runs.

Benefits of Spot Color Printing

Spot color printing provides precise color consistency and vibrant hues unmatched by the four-color process, making it ideal for brand logos and corporate identity materials. It reduces ink usage and production costs for jobs requiring limited colors, improving efficiency and turnaround time. Spot colors also enhance print durability and ensure accurate color matching across various substrates, crucial for maintaining brand integrity.

Cost Comparison: Four-Color vs Spot Color

Four-color process printing typically incurs higher costs due to the complexity of mixing cyan, magenta, yellow, and black inks to achieve a full spectrum of colors, making it ideal for full-color images. Spot color printing uses pre-mixed inks, resulting in lower costs for designs with limited colors and ensuring color consistency across prints. Your choice impacts budget efficiency depending on the project's color requirements and print run size.

Best Use Cases for Four-Color Process

Four-color process printing excels in reproducing vibrant, detailed images with smooth gradients, making it ideal for photographic prints, marketing materials, and full-color brochures. It uses cyan, magenta, yellow, and black inks (CMYK) to create a wide spectrum of colors through layering. Spot color is better suited for projects requiring precise color matching or limited color palettes, such as logos or brand-specific designs.

When to Choose Spot Color Printing

Spot color printing is ideal when precise color matching is crucial, such as in brand logos or corporate materials requiring specific Pantone shades. It offers vibrant, consistent colors that are difficult to achieve with the four-color process, especially for solid areas of color. Choosing spot colors reduces the risk of color variation and can be more cost-effective for jobs with limited color requirements.

Conclusion: Selecting the Right Printing Method

Choosing between four-color process and spot color printing depends on your project's color complexity and brand consistency requirements. Four-color process excels in reproducing full-color images with gradient tones, ideal for detailed photographs and complex designs. Spot color offers precise color matching and cost-effectiveness for limited-color jobs, making it a strategic choice for logos and branded materials.

Four-color process vs spot color Infographic

libmatt.com

libmatt.com