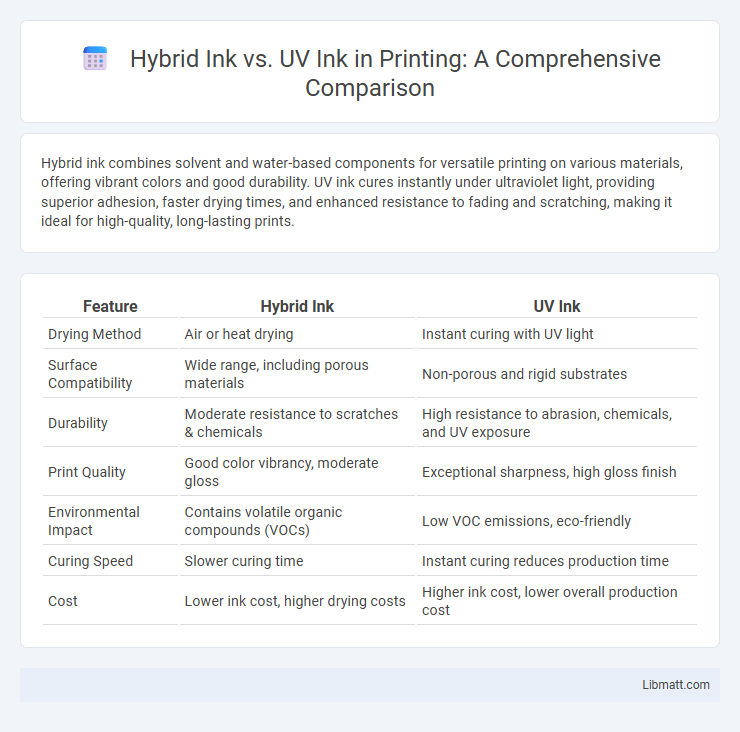

Hybrid ink combines solvent and water-based components for versatile printing on various materials, offering vibrant colors and good durability. UV ink cures instantly under ultraviolet light, providing superior adhesion, faster drying times, and enhanced resistance to fading and scratching, making it ideal for high-quality, long-lasting prints.

Table of Comparison

| Feature | Hybrid Ink | UV Ink |

|---|---|---|

| Drying Method | Air or heat drying | Instant curing with UV light |

| Surface Compatibility | Wide range, including porous materials | Non-porous and rigid substrates |

| Durability | Moderate resistance to scratches & chemicals | High resistance to abrasion, chemicals, and UV exposure |

| Print Quality | Good color vibrancy, moderate gloss | Exceptional sharpness, high gloss finish |

| Environmental Impact | Contains volatile organic compounds (VOCs) | Low VOC emissions, eco-friendly |

| Curing Speed | Slower curing time | Instant curing reduces production time |

| Cost | Lower ink cost, higher drying costs | Higher ink cost, lower overall production cost |

Introduction to Hybrid Ink and UV Ink

Hybrid ink combines the benefits of solvent and water-based inks, offering vibrant colors with enhanced durability and faster drying times, ideal for versatile printing applications. UV ink cures instantly when exposed to ultraviolet light, providing superior adhesion, resistance to fading, and environmental advantages due to low VOC emissions. Choosing between hybrid and UV ink depends on your project requirements, including substrate type, durability expectations, and environmental considerations.

Key Differences Between Hybrid Ink and UV Ink

Hybrid ink combines solvent and water-based components, providing vibrant colors with faster drying times and greater flexibility on various surfaces. UV ink cures instantly using ultraviolet light, resulting in superior durability, scratch resistance, and eco-friendly properties due to low VOC emissions. Understanding these key differences helps you choose the ideal ink type for your specific printing needs and substrate compatibility.

How Hybrid Ink Works

Hybrid ink combines the fast-drying properties of solvent-based inks with the vibrant colors of UV-curable inks, enabling efficient and high-quality printing on diverse materials. It works by curing through both solvent evaporation and UV light exposure, ensuring strong adhesion and enhanced durability on surfaces like plastics, glass, and metals. Your printing projects benefit from reduced drying times and improved resistance to scratches and chemicals.

How UV Ink Works

UV ink works by using ultraviolet light to instantly cure and dry the ink on the substrate's surface, creating a durable and vibrant print. This process involves photoinitiators in the ink that react to UV light, causing rapid polymerization and solidification without the need for heat. Your printed materials benefit from enhanced scratch resistance and color stability due to the ink's immediate hardening.

Print Quality Comparison: Hybrid vs UV Ink

Hybrid ink offers vibrant colors and smooth gradients, ideal for high-resolution prints on flexible materials, while UV ink delivers sharper details and faster curing on rigid surfaces, ensuring durability and scratch resistance. Your choice depends on the substrate and project requirements, with hybrid ink excelling in flexibility and UV ink providing superior precision and longevity. Both inks maintain excellent print quality, but UV ink often outperforms in environments demanding quick drying and robust finishes.

Applications and Use Cases

Hybrid ink combines the flexibility of solvent-based inks with the vibrancy of UV inks, making it ideal for outdoor signage and flexible packaging due to its superior adhesion on diverse materials like vinyl and polyethylene. UV ink cures instantly under ultraviolet light, providing excellent durability and resistance to fading, commonly used in high-quality commercial printing, electronics labeling, and promotional products. Both inks serve distinct applications where hybrid ink excels in versatility and UV ink in fast curing and detailed print quality.

Durability and Longevity

Hybrid ink combines solvent and water-based components, offering enhanced flexibility and resistance to fading, scratches, and environmental factors, thus providing durable print results suitable for various surfaces. UV ink cures instantly under ultraviolet light, creating a hard, resilient coating that delivers exceptional longevity, superior resistance to abrasion, and excellent color retention even in harsh outdoor conditions. Compared to UV ink, hybrid ink provides moderate durability with better adaptability, while UV ink excels in long-term wear and outdoor durability for industrial and commercial applications.

Cost Considerations

Hybrid ink offers a cost-effective solution by combining solvent and UV technologies, reducing the need for expensive curing equipment and minimizing material waste. UV ink typically involves higher upfront costs due to specialized curing lamps and maintenance, but it provides faster drying times and enhanced durability, which may justify the investment for high-volume production. Your choice depends on balancing initial expenses with long-term operational efficiency and application requirements.

Environmental Impact

Hybrid ink combines conventional solvent-based components with UV-curable monomers, resulting in lower volatile organic compound (VOC) emissions compared to traditional solvent inks but higher than pure UV inks. UV ink utilizes ultraviolet light for instant curing, producing minimal VOC emissions and generating less hazardous waste, making it more environmentally friendly. The reduced environmental impact of UV ink supports sustainability efforts by lowering air pollution and minimizing landfill contamination.

Choosing the Right Ink for Your Printing Needs

Hybrid ink combines the durability and fast drying properties of solvent-based inks with the vibrant colors and environmental benefits of water-based inks, making it suitable for both indoor and outdoor printing applications. UV ink cures instantly under ultraviolet light, providing exceptional sharpness, resistance to fading, and adhesion to a wide range of surfaces, ideal for high-quality, long-lasting prints. Your choice depends on your printing needs: opt for hybrid ink for versatility and eco-friendliness, or UV ink when demanding durability and superior print quality.

Hybrid Ink vs UV Ink Infographic

libmatt.com

libmatt.com