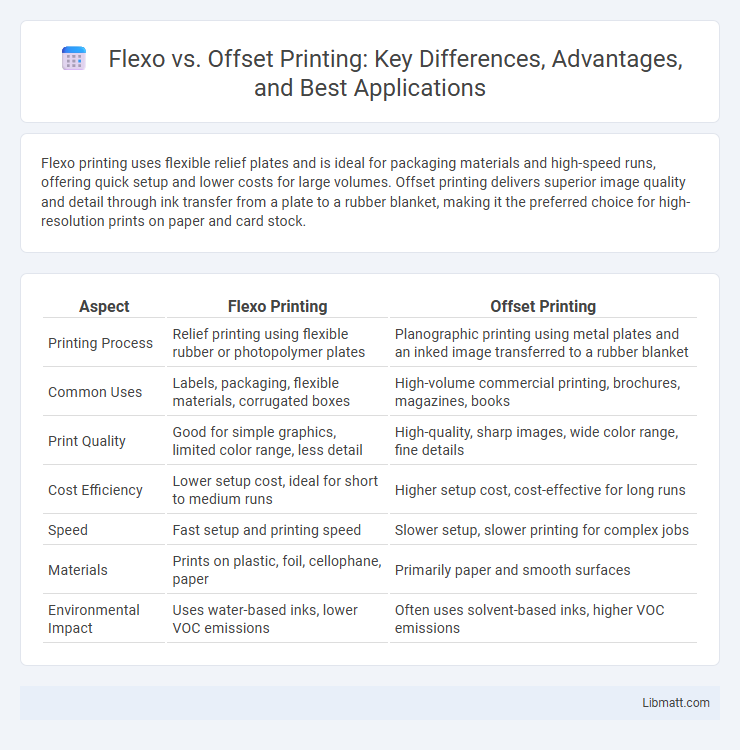

Flexo printing uses flexible relief plates and is ideal for packaging materials and high-speed runs, offering quick setup and lower costs for large volumes. Offset printing delivers superior image quality and detail through ink transfer from a plate to a rubber blanket, making it the preferred choice for high-resolution prints on paper and card stock.

Table of Comparison

| Aspect | Flexo Printing | Offset Printing |

|---|---|---|

| Printing Process | Relief printing using flexible rubber or photopolymer plates | Planographic printing using metal plates and an inked image transferred to a rubber blanket |

| Common Uses | Labels, packaging, flexible materials, corrugated boxes | High-volume commercial printing, brochures, magazines, books |

| Print Quality | Good for simple graphics, limited color range, less detail | High-quality, sharp images, wide color range, fine details |

| Cost Efficiency | Lower setup cost, ideal for short to medium runs | Higher setup cost, cost-effective for long runs |

| Speed | Fast setup and printing speed | Slower setup, slower printing for complex jobs |

| Materials | Prints on plastic, foil, cellophane, paper | Primarily paper and smooth surfaces |

| Environmental Impact | Uses water-based inks, lower VOC emissions | Often uses solvent-based inks, higher VOC emissions |

Introduction to Flexo and Offset Printing

Flexo and offset printing are two prominent methods in the printing industry, each offering unique advantages for different applications. Flexo printing uses flexible rubber or polymer plates and fast-drying inks, making it ideal for packaging, labels, and non-porous surfaces, while offset printing relies on lithographic plates transferring ink onto a rubber blanket and then paper, delivering high-quality images for commercial print jobs such as brochures and magazines. Your choice between flexo and offset printing will depend on factors like print volume, material type, and desired image quality.

Key Differences Between Flexo and Offset

Flexo printing uses flexible relief plates and fast-drying inks, making it ideal for packaging and labels on various substrates like plastic, foil, and paper. Offset printing employs flat, smooth plates and oil-based inks, delivering high-quality, detailed images best suited for large-volume print runs on paper stock. Key differences include plate material, ink type, substrate compatibility, and cost-effectiveness, with flexo excelling in speed and versatility, while offset offers superior image resolution and color fidelity.

How Flexographic Printing Works

Flexographic printing operates by using flexible relief plates made of rubber or photopolymer, which transfer ink onto various substrates through direct contact. The process involves an anilox roller that meters a precise amount of ink, ensuring consistent color density and sharp image reproduction on materials such as plastic, metallic films, and paper. This method excels in high-speed production runs and is widely used for packaging applications due to its adaptability to diverse surfaces and quick drying inks.

How Offset Printing Works

Offset printing transfers ink from a metal plate to a rubber blanket before applying it to the printing surface, ensuring sharp and consistent images. The process uses a series of rollers to press inked plates against paper, making it ideal for high-volume print runs with precise color reproduction. Your choice of offset printing guarantees high-quality output for detailed graphics and text, especially on flat, smooth surfaces.

Print Quality Comparison: Flexo vs Offset

Offset printing delivers superior print quality with higher resolution and finer detail, making it ideal for intricate designs and photographic images. Flexographic printing provides good quality but is better suited for simpler graphics and large runs on flexible packaging due to its ability to print on a variety of substrates. The choice depends on the balance between image clarity requirements and production efficiency.

Cost Analysis: Flexo vs Offset

Flexo printing generally offers lower setup costs compared to offset, making it more cost-effective for shorter print runs and flexible packaging. Offset printing involves higher initial expenses due to plate creation but becomes more economical for large volume jobs due to its faster production speed and superior image quality. Your choice between flexo vs offset should weigh the volume and complexity of the print project against the specific cost benefits each method provides.

Substrate Compatibility

Flexo printing excels in substrate compatibility, handling a wide range of materials including plastic films, foil, paper, and corrugated cardboard. Offset printing is primarily suited for flat, smooth surfaces such as coated paper and cardstock but struggles with non-standard or flexible substrates. Flexography's ability to print on diverse and non-porous substrates offers significant advantages for packaging and labels.

Environmental Impact: Flexo vs Offset

Flexographic printing uses water-based inks and produces less waste, making it more environmentally friendly compared to offset printing, which relies heavily on solvent-based inks and generates significant chemical waste. Flexo's efficient ink usage and faster drying time reduce energy consumption, whereas offset printing often requires additional drying processes that increase its carbon footprint. Choosing flexo printing can help your business lower its environmental impact while maintaining high-quality output.

Industry Applications and Use Cases

Flexo printing is widely used in packaging industries such as food, beverage, and pharmaceuticals due to its ability to print on diverse substrates like plastic, foil, and paper. Offset printing dominates in high-volume commercial printing for books, newspapers, and magazines, offering superior image quality and consistent color reproduction. Both methods serve distinct market needs, with flexo excelling in flexible packaging and offset preferred for detailed graphics and large print runs.

Choosing the Right Printing Method for Your Needs

Flexo printing excels in high-volume runs with fast drying times and works well on flexible packaging materials, making it ideal for large-scale projects. Offset printing provides superior image quality and color accuracy, preferred for detailed graphics and smaller print runs like brochures or business cards. Your decision should consider factors such as print quantity, material type, and desired image detail to select the most efficient and cost-effective method.

Flexo vs Offset Infographic

libmatt.com

libmatt.com