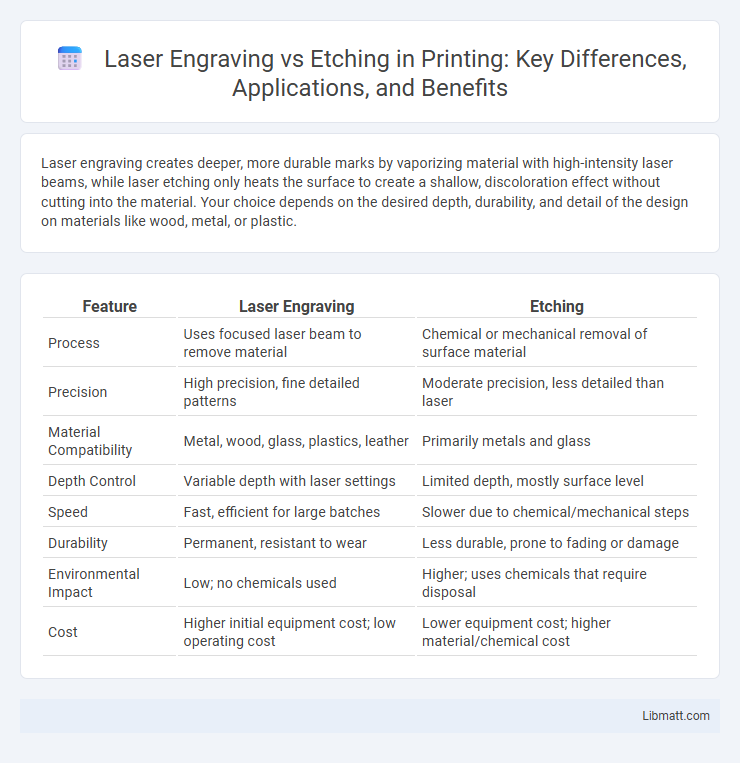

Laser engraving creates deeper, more durable marks by vaporizing material with high-intensity laser beams, while laser etching only heats the surface to create a shallow, discoloration effect without cutting into the material. Your choice depends on the desired depth, durability, and detail of the design on materials like wood, metal, or plastic.

Table of Comparison

| Feature | Laser Engraving | Etching |

|---|---|---|

| Process | Uses focused laser beam to remove material | Chemical or mechanical removal of surface material |

| Precision | High precision, fine detailed patterns | Moderate precision, less detailed than laser |

| Material Compatibility | Metal, wood, glass, plastics, leather | Primarily metals and glass |

| Depth Control | Variable depth with laser settings | Limited depth, mostly surface level |

| Speed | Fast, efficient for large batches | Slower due to chemical/mechanical steps |

| Durability | Permanent, resistant to wear | Less durable, prone to fading or damage |

| Environmental Impact | Low; no chemicals used | Higher; uses chemicals that require disposal |

| Cost | Higher initial equipment cost; low operating cost | Lower equipment cost; higher material/chemical cost |

Introduction to Laser Engraving and Etching

Laser engraving creates deep, precise marks by vaporizing material layers, producing durable and tactile designs ideal for detailed customization. Laser etching removes only a thin surface layer, resulting in subtle, fragile markings suited for delicate or decorative applications. Your choice between laser engraving and etching depends on desired design depth, material type, and longevity requirements.

What is Laser Engraving?

Laser engraving uses a high-powered laser beam to precisely remove material from a surface, creating deep, permanent marks or designs by vaporizing or melting the substrate. This process achieves three-dimensional depth and texture, making it ideal for detailed logos, serial numbers, and industrial parts. Common materials for laser engraving include wood, metal, glass, and plastic, where the laser's intensity and speed are adjusted for optimal results.

What is Laser Etching?

Laser etching is a precise process that uses laser beams to create shallow marks or designs on a material's surface without removing much material, resulting in a raised or slightly recessed pattern. Unlike laser engraving, which cuts deeper into the substrate, laser etching alters the material's surface at a microscopic level for finer detail and faster production. Your choice between laser engraving and etching depends on the desired depth and durability of the design, as well as the material being used.

Key Differences Between Engraving and Etching

Laser engraving removes material from the surface to create deep, precise designs, while laser etching alters the surface without cutting deeply, resulting in shallow, subtle marks. Engraving is ideal for intricate, permanent markings on hard materials like metal and glass, whereas etching suits delicate surfaces and faster production with less depth. The choice depends on desired durability, detail, and material compatibility, with engraving offering greater permanence and etching providing versatility.

Materials Suitable for Engraving vs. Etching

Laser engraving effectively processes a variety of materials including metals such as stainless steel and aluminum, plastics like acrylic and ABS, as well as wood, leather, and glass. Laser etching suits primarily metals with coatings or anodized surfaces, creating a surface-level mark without deep material removal, ideal for aluminum anodized parts, coated metals, and painted surfaces. The choice between engraving and etching hinges on the material's hardness and desired depth, with engraving providing deeper, permanent marks on a broader range of substrates.

Precision and Detail Comparison

Laser engraving delivers superior precision and intricate detail due to its ability to remove material layer by layer with high accuracy, producing deep, sharp designs. Laser etching, while also precise, typically affects only the surface by slightly altering its color or texture without cutting deeply, resulting in finer but less pronounced details. The choice between engraving and etching depends on the desired depth and detail, with engraving excelling in depth-driven precision and etching offering subtle surface detail enhancements.

Speed and Efficiency: Engraving vs. Etching

Laser engraving generally offers faster processing times than etching due to its ability to remove material more aggressively and create deeper, more precise markings in a single pass. Etching, which relies on surface-level chemical or laser alterations, tends to be slower because it requires multiple passes or longer exposure to achieve the desired design depth and detail. Efficiency is often higher with engraving for large-scale or complex projects, while etching suits applications needing subtle, shallow markings with finer detail.

Durability and Depth of Markings

Laser engraving creates deeper, more durable markings by vaporizing material to form permanent grooves, ensuring long-lasting visibility even under harsh conditions. Laser etching produces shallower, less aggressive marks by softening the surface without fully penetrating it, which may wear off more easily over time. The increased depth and precision of laser engraving make it ideal for industrial applications requiring high resistance to abrasion and fading.

Applications and Industries for Each Method

Laser engraving excels in creating precise and deep markings ideal for industrial parts, electronics, and medical devices, where durability and readability are critical. Laser etching is preferred in applications requiring shallow, high-contrast markings such as branding on glassware, jewelry, and promotional products, offering fast processing without material damage. Both techniques find extensive use in manufacturing, aerospace, automotive, and decorative arts, with engraving suited for functional components and etching for aesthetic or temporary markings.

Choosing the Right Process for Your Project

Laser engraving removes material to create a deep, permanent mark, ideal for intricate designs and durable finishes on metals, plastics, and wood. Etching uses a chemical or laser to alter the surface without cutting deeply, producing subtle, delicate patterns suited for decorative applications. Evaluate your project's material, detail level, and longevity requirements to choose the process that ensures your desired outcome.

Laser engraving vs etching Infographic

libmatt.com

libmatt.com