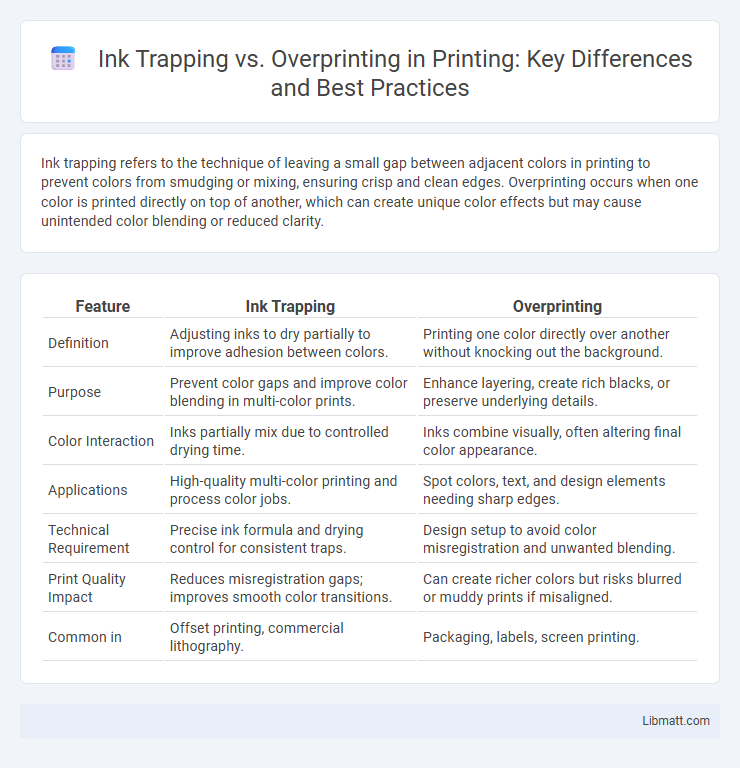

Ink trapping refers to the technique of leaving a small gap between adjacent colors in printing to prevent colors from smudging or mixing, ensuring crisp and clean edges. Overprinting occurs when one color is printed directly on top of another, which can create unique color effects but may cause unintended color blending or reduced clarity.

Table of Comparison

| Feature | Ink Trapping | Overprinting |

|---|---|---|

| Definition | Adjusting inks to dry partially to improve adhesion between colors. | Printing one color directly over another without knocking out the background. |

| Purpose | Prevent color gaps and improve color blending in multi-color prints. | Enhance layering, create rich blacks, or preserve underlying details. |

| Color Interaction | Inks partially mix due to controlled drying time. | Inks combine visually, often altering final color appearance. |

| Applications | High-quality multi-color printing and process color jobs. | Spot colors, text, and design elements needing sharp edges. |

| Technical Requirement | Precise ink formula and drying control for consistent traps. | Design setup to avoid color misregistration and unwanted blending. |

| Print Quality Impact | Reduces misregistration gaps; improves smooth color transitions. | Can create richer colors but risks blurred or muddy prints if misaligned. |

| Common in | Offset printing, commercial lithography. | Packaging, labels, screen printing. |

Understanding Ink Trapping: Basics and Importance

Ink trapping refers to the intentional overlapping of wet ink on a previously printed ink layer to ensure color accuracy and sharpness in printing processes, especially in offset and flexographic printing. Understanding the basics of ink trapping is crucial for minimizing issues like color shifts and blurred edges, thereby maintaining the integrity of printed materials. Proper ink trapping enhances print quality by compensating for ink spread and dot gain, leading to consistent and precise color reproduction.

Overprinting Explained: How It Works in Printing

Overprinting in printing involves layering one color of ink directly on top of another without knocking out the underlying color, ensuring smoother color transitions and preventing white gaps in registration. This technique is essential in processes like offset and screen printing to maintain image integrity, especially in areas with overlapping colors or fine details. Ink trapping, on the other hand, focuses on compensating for ink spread by slightly overlapping colors to avoid gaps, but overprinting specifically refers to the deliberate overlay of inks to blend colors and enhance print quality.

Key Differences Between Ink Trapping and Overprinting

Ink trapping involves creating small gaps between colors to prevent ink from mixing and ensure sharp edges during printing, whereas overprinting intentionally layers one color over another to produce rich color effects or avoid registration issues. Ink trapping is primarily a technical adjustment in press setup to improve print quality, while overprinting is a design choice used to achieve specific visual outcomes. Understanding the distinction helps optimize print accuracy and aesthetic results in multicolor printing processes.

When to Use Ink Trapping in Print Design

Ink trapping is essential when printing with multiple colors on slow-drying stocks or with high-speed presses to prevent colors from visually separating due to misregistration. Overprinting is suitable for layering colors without knocking out underlying inks, but ink trapping specifically compensates for ink spread and misalignment in your design, ensuring crisp, clean edges. You should use ink trapping in print design when precise color alignment is critical and your project involves complex overlapping elements or fine details.

Best Scenarios for Applying Overprinting

Overprinting is best suited for scenarios where precise color registration is critical, such as in text or fine line artwork, to avoid gaps caused by misalignment. It is ideal for printing spot colors or when layering dark inks over lighter backgrounds to enhance color richness and avoid unwanted knockouts. Overprinting simplifies the printing process in multi-color jobs by allowing inks to blend naturally on the paper, reducing the risk of white space or halos.

Print Quality: Impact of Ink Trapping vs Overprinting

Ink trapping ensures crisper, more accurate color reproduction by controlling the spread between adjacent inks, reducing blurring and dot gain for superior print quality. Overprinting can intensify colors and create unique effects but may lead to unintended color shifts and reduced sharpness where inks overlap. Your choice between ink trapping and overprinting directly affects the final visual precision and vibrancy of printed materials.

Common Challenges and Solutions in Ink Trapping

Ink trapping and overprinting often present challenges such as color shifts, registration errors, and ink bleed, which can compromise print quality. Effective solutions include precise calibration of printing presses, optimized trap widths tailored to ink properties, and digital proofing to anticipate and correct trapping issues before production. Advanced software tools that simulate ink behavior help designers adjust trap settings, minimizing overlaps and ensuring sharp, consistent color reproduction.

Avoiding Mistakes with Overprinting Techniques

Ink trapping and overprinting are essential techniques in print production to ensure color accuracy and sharpness. Avoiding mistakes with overprinting involves carefully managing the registration and ink density to prevent undesirable color shifts or muddy prints. Proper prepress checks and simulation tools help detect potential issues, ensuring smooth overlaps and maintaining the intended design quality.

Prepress Workflow: Integrating Trapping and Overprinting

In the prepress workflow, integrating trapping and overprinting enhances print quality by managing color overlaps and preventing gaps between adjacent colors. Trapping adjusts the edges of colors to create slight overlaps, compensating for misregistration during printing, while overprinting allows one color to be printed directly over another without knocking out the background. Effective coordination of trapping and overprinting processes within RIP software and color separation stages ensures accurate color reproduction and reduces print defects in complex color layouts.

Industry Standards and Best Practices for Print Results

Ink trapping ensures precise alignment and color blending by allowing wet ink to adhere to slightly dried ink during printing, following stringent industry standards such as ISO 12647 for color consistency. Overprinting, commonly used for complex images and special effects, requires careful application to prevent color distortion and achieve accurate reproduction in compliance with best practices outlined by the Ghent Workgroup specifications. Your print projects benefit from understanding these techniques to maintain sharpness, richness, and fidelity across multiple print runs.

ink trapping vs overprinting Infographic

libmatt.com

libmatt.com