Spot color delivers precise, consistent hues by using pre-mixed inks in printing, ideal for brand logos requiring exact color matching. Process color, created through layering cyan, magenta, yellow, and black inks, offers a wider color range and is best for full-color images and photographs.

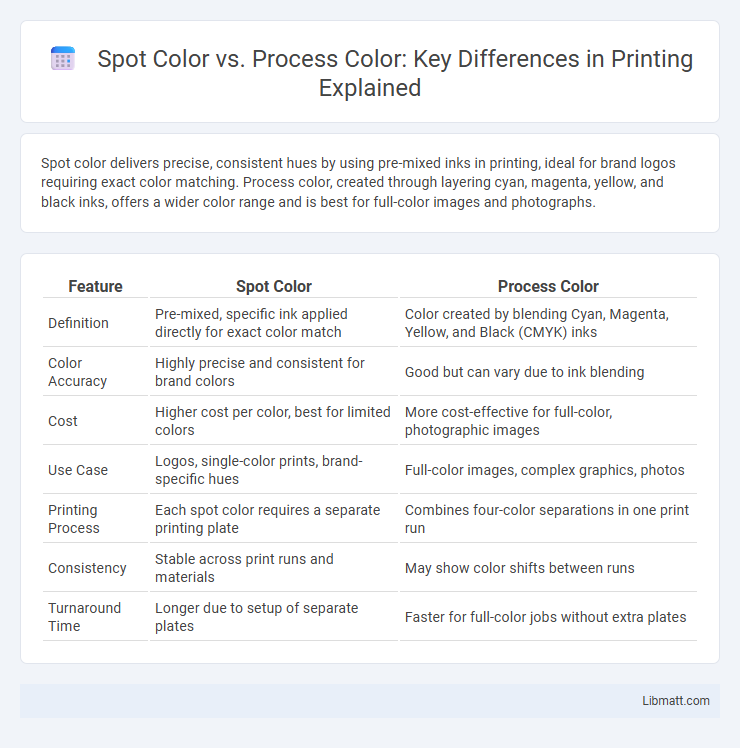

Table of Comparison

| Feature | Spot Color | Process Color |

|---|---|---|

| Definition | Pre-mixed, specific ink applied directly for exact color match | Color created by blending Cyan, Magenta, Yellow, and Black (CMYK) inks |

| Color Accuracy | Highly precise and consistent for brand colors | Good but can vary due to ink blending |

| Cost | Higher cost per color, best for limited colors | More cost-effective for full-color, photographic images |

| Use Case | Logos, single-color prints, brand-specific hues | Full-color images, complex graphics, photos |

| Printing Process | Each spot color requires a separate printing plate | Combines four-color separations in one print run |

| Consistency | Stable across print runs and materials | May show color shifts between runs |

| Turnaround Time | Longer due to setup of separate plates | Faster for full-color jobs without extra plates |

Introduction to Spot Color and Process Color

Spot color refers to a specific, pre-mixed ink applied during printing to achieve consistent and precise color matching, often used for logos and brand colors. Process color relies on the four-color CMYK model--cyan, magenta, yellow, and black--layered to produce a wide range of colors through halftone printing. Understanding the distinction between spot color and process color is essential for selecting the appropriate printing method based on color accuracy and budget requirements.

Understanding Spot Color: Definition and Uses

Spot color refers to a specific, pre-mixed ink used in printing to achieve consistent and precise hues that are difficult to replicate with standard process colors. It is commonly used for brand logos, packaging, and designs requiring exact color matching, ensuring uniformity across various print runs. Spot colors are especially valuable in situations where color accuracy and vibrancy are critical, such as in corporate branding and premium product labels.

What Is Process Color? A Detailed Overview

Process color refers to a color printing method that uses four primary ink colors--cyan, magenta, yellow, and black (CMYK)--to create a wide spectrum of colors by overlapping varying percentages of these inks. This technique is essential for producing detailed images and vibrant designs in magazines, brochures, and packaging where accurate color reproduction is critical. When choosing between spot color and process color, your decision hinges on the need for precise color matching versus broad color range flexibility.

Key Differences Between Spot Color and Process Color

Spot color uses pre-mixed inks applied individually to ensure precise, consistent hues, ideal for brand colors requiring exact replication. Process color relies on the CMYK color model, layering cyan, magenta, yellow, and black inks to produce a wide gamut of colors through halftone dots. Spot color excels in solid, vibrant shades with minimal variation, while process color enables complex gradients and full-color images but may vary slightly between prints.

Advantages of Spot Color Printing

Spot color printing offers precise color matching using pre-mixed inks, ensuring consistent and vibrant hues ideal for brand logos and corporate identities. It reduces ink usage and drying time compared to process color printing, enhancing production efficiency and cost-effectiveness for short runs. Spot colors provide superior opacity on various substrates, delivering sharp and bold visuals that stand out on packaging and promotional materials.

Benefits of Using Process Color in Design

Process color in design offers the advantage of reproducing a wide spectrum of colors through the CMYK color model, enabling vibrant and precise color gradients that spot color cannot achieve. This method is cost-effective for projects requiring multiple hues since it uses a combination of four inks, reducing the need for custom-mixed pigments. Process color ensures consistent color reproduction across different print runs, making it ideal for complex images like photographs and detailed graphics.

When to Choose Spot Color Over Process Color

Spot color is ideal for projects requiring precise color matching, such as brand logos and corporate identity materials, where color consistency is crucial. It is preferred for limited color palettes, special inks like metallic or fluorescent, and when printing on non-white or colored substrates. Selecting spot color over process color ensures vibrant, solid colors without the risk of color variation inherent in CMYK process printing.

Common Applications of Spot and Process Colors

Spot colors are widely used in branding, packaging, and logos requiring precise color matching and consistency across print runs. Process colors excel in full-color images, such as photographs and detailed illustrations, where a broad spectrum of shades is needed through CMYK color mixing. When selecting colors for Your project, consider spot colors for vibrant, exact hues and process colors for complex, multi-colored designs.

Cost Considerations: Spot vs Process Color

Spot color printing typically incurs lower costs for short runs or projects requiring precise color matching, as it uses pre-mixed inks that reduce setup time and ink waste. Process color printing, relying on CMYK inks, is more cost-effective for full-color images and high-volume production due to its ability to produce a wide color range without additional ink plates. Understanding your project's color needs and volume can help you choose the most economical option between spot color and process color printing.

Choosing the Right Color Method for Your Project

Choosing the right color method for your project significantly impacts the final print quality and cost-effectiveness. Spot colors use pre-mixed inks that ensure consistent, vibrant hues ideal for logos and brand-specific colors, while process colors rely on CMYK printing to create a wide range of shades through layering. Evaluating your project's color precision, budget constraints, and printing volume helps determine whether spot or process color best suits your needs.

Spot Color vs Process Color Infographic

libmatt.com

libmatt.com