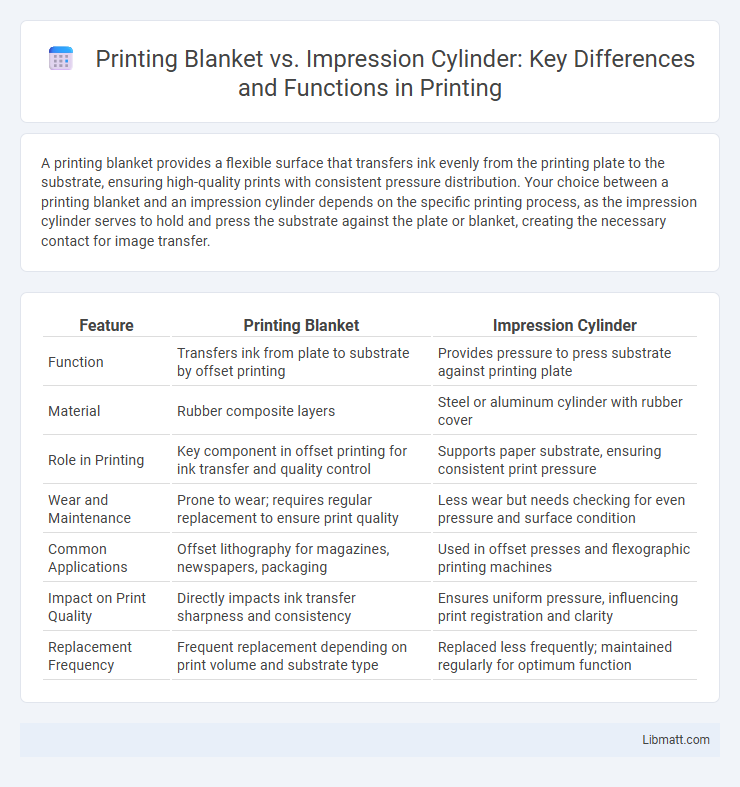

A printing blanket provides a flexible surface that transfers ink evenly from the printing plate to the substrate, ensuring high-quality prints with consistent pressure distribution. Your choice between a printing blanket and an impression cylinder depends on the specific printing process, as the impression cylinder serves to hold and press the substrate against the plate or blanket, creating the necessary contact for image transfer.

Table of Comparison

| Feature | Printing Blanket | Impression Cylinder |

|---|---|---|

| Function | Transfers ink from plate to substrate by offset printing | Provides pressure to press substrate against printing plate |

| Material | Rubber composite layers | Steel or aluminum cylinder with rubber cover |

| Role in Printing | Key component in offset printing for ink transfer and quality control | Supports paper substrate, ensuring consistent print pressure |

| Wear and Maintenance | Prone to wear; requires regular replacement to ensure print quality | Less wear but needs checking for even pressure and surface condition |

| Common Applications | Offset lithography for magazines, newspapers, packaging | Used in offset presses and flexographic printing machines |

| Impact on Print Quality | Directly impacts ink transfer sharpness and consistency | Ensures uniform pressure, influencing print registration and clarity |

| Replacement Frequency | Frequent replacement depending on print volume and substrate type | Replaced less frequently; maintained regularly for optimum function |

Introduction to Printing Blankets and Impression Cylinders

Printing blankets and impression cylinders are essential components in offset printing, each serving distinct functions to ensure print quality. Printing blankets provide a flexible surface that transfers ink from the plate to the paper, absorbing pressure to produce sharp images. Impression cylinders press the paper against the printing blanket, controlling registration and pressure to maintain precise print alignment.

Key Functions: Printing Blanket vs Impression Cylinder

Printing blankets provide a cushioned surface that ensures even transfer of ink from the printing plate to the substrate, enhancing image quality and reducing surface defects. Impression cylinders apply consistent pressure to hold the substrate firmly against the printing plate or blanket, ensuring precise ink transfer and registration during the printing process. Together, the printing blanket and impression cylinder play crucial roles in offset printing by balancing ink distribution and pressure application for high-quality prints.

Material Composition and Durability

Printing blankets are typically made from layers of rubber and fabric, providing excellent flexibility and resilience for consistent print quality, while impression cylinders are constructed from metal, usually steel or aluminum, offering robust structural support and durability. The rubber composition of printing blankets allows them to absorb pressure and accommodate surface irregularities, enhancing print detail and longevity. Your choice depends on balancing the blanket's adaptability with the cylinder's strength to ensure optimal performance in printing operations.

Role in Offset Printing Process

The printing blanket plays a critical role in the offset printing process by transferring the inked image from the plate cylinder to the paper, ensuring even pressure and high-quality prints. The impression cylinder provides the necessary support by pressing the substrate firmly against the printing blanket, facilitating precise image transfer. Your understanding of these components helps optimize print quality and maintain machine efficiency.

Surface Characteristics and Print Quality

The printing blanket features a soft, compressible surface that allows ink to transfer smoothly onto various substrates, resulting in consistent and high-quality prints. In contrast, the impression cylinder has a hard, rigid surface designed to apply uniform pressure during the printing process, which helps maintain precise image definition but may offer less cushioning impact. Your choice between a printing blanket and an impression cylinder will directly affect the surface texture and sharpness of the final print.

Common Issues and Maintenance Needs

Printing blankets often face common issues such as wear and tear, delamination, and contamination from ink or adhesives, requiring regular cleaning and timely replacement to maintain print quality. Impression cylinders frequently suffer from surface damage, ink buildup, and mechanical misalignment, necessitating routine inspection, precise calibration, and cleaning to ensure accurate pressure distribution and consistent impressions. Proper maintenance schedules for both components are crucial in preventing downtime and preserving the overall efficiency of the printing process.

Cost Implications and Replacement Frequency

Printing blankets generally offer lower initial costs and are replaced more frequently due to wear and tear, impacting ongoing maintenance expenses. Impression cylinders, though having a higher upfront investment, tend to have longer lifespans and less frequent replacements, reducing downtime and long-term costs. Your choice between the two should consider both the immediate budget and the anticipated frequency of part replacement for optimal cost-efficiency.

Impact on Ink Transfer Efficiency

Printing blankets provide a flexible surface that evenly distributes pressure, enhancing ink transfer efficiency by reducing ink starvation and ensuring uniform coverage on the substrate. Impression cylinders, while offering rigid support, can cause less consistent contact, potentially leading to uneven ink transfer and increased maintenance requirements. Optimizing the combination of a high-quality printing blanket with a well-maintained impression cylinder significantly improves overall printing quality and ink transfer efficiency.

Technological Advancements and Innovations

Printing blankets have evolved with advanced rubber compounds and enhanced compressibility, improving ink transfer precision and durability in modern flexographic and offset presses. Impression cylinders have incorporated innovative materials such as lightweight alloys and precision-engineered surfaces to ensure consistent pressure distribution and minimize mechanical wear during high-speed printing. These technological advancements collectively enhance print quality, reduce downtime, and increase overall efficiency in contemporary printing processes.

Choosing Between Printing Blanket and Impression Cylinder

Choosing between a printing blanket and an impression cylinder depends on your specific printing needs and equipment compatibility. Printing blankets offer flexibility for offset presses by providing a cushioned surface that ensures high-quality image transfer and reduces wear on plates. Impression cylinders, essential in flexographic and gravure printing, apply uniform pressure for consistent print quality on various substrates, making them ideal for high-speed, large-volume production.

Printing blanket vs impression cylinder Infographic

libmatt.com

libmatt.com