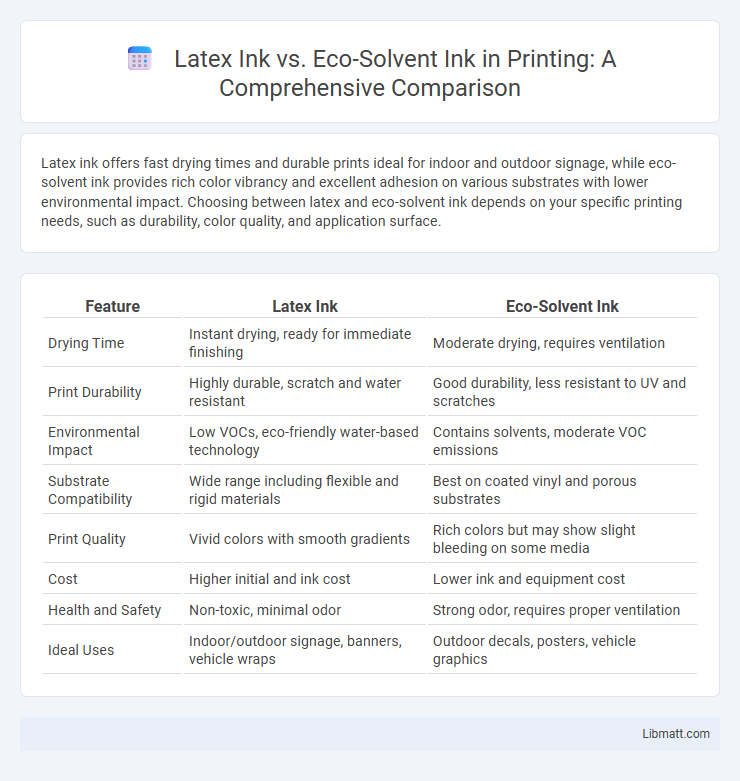

Latex ink offers fast drying times and durable prints ideal for indoor and outdoor signage, while eco-solvent ink provides rich color vibrancy and excellent adhesion on various substrates with lower environmental impact. Choosing between latex and eco-solvent ink depends on your specific printing needs, such as durability, color quality, and application surface.

Table of Comparison

| Feature | Latex Ink | Eco-Solvent Ink |

|---|---|---|

| Drying Time | Instant drying, ready for immediate finishing | Moderate drying, requires ventilation |

| Print Durability | Highly durable, scratch and water resistant | Good durability, less resistant to UV and scratches |

| Environmental Impact | Low VOCs, eco-friendly water-based technology | Contains solvents, moderate VOC emissions |

| Substrate Compatibility | Wide range including flexible and rigid materials | Best on coated vinyl and porous substrates |

| Print Quality | Vivid colors with smooth gradients | Rich colors but may show slight bleeding on some media |

| Cost | Higher initial and ink cost | Lower ink and equipment cost |

| Health and Safety | Non-toxic, minimal odor | Strong odor, requires proper ventilation |

| Ideal Uses | Indoor/outdoor signage, banners, vehicle wraps | Outdoor decals, posters, vehicle graphics |

Introduction to Latex and Eco-Solvent Inks

Latex ink utilizes water-based polymer dispersion, delivering vibrant, durable prints with quick drying times, making it ideal for indoor and outdoor applications. Eco-solvent ink contains mild solvents that dissolve the pigment, offering excellent color vibrancy and resistance on coated and uncoated media, favored in signage and vehicle wraps. Both inks emphasize environmental safety, with latex ink producing low odor and eco-solvent ink minimizing volatile organic compounds (VOCs).

Chemical Composition and Properties

Latex ink consists of water-based polymers combined with pigments and additives, creating a flexible, durable print that resists scratching and environmental exposure. Eco-solvent ink incorporates modified solvents and resins that dissolve pigments, enhancing adhesion and producing vibrant colors on vinyl and coated materials. Latex ink dries quickly through heat, making it odorless and eco-friendlier, while eco-solvent ink evaporates solvents during curing, offering robust outdoor durability but with moderate VOC emissions.

Print Quality and Color Vibrancy

Latex ink offers high print quality with sharp details and smooth gradients, suitable for indoor and outdoor applications due to its water resistance and durability. Eco-solvent ink produces vibrant, rich colors with excellent color saturation and subtle tonal variations, ideal for photo-realistic prints and long-lasting outdoor signage. Both inks provide impressive print quality, but eco-solvent ink typically surpasses latex in color vibrancy, especially on coated media.

Substrate Compatibility

Latex ink offers versatile substrate compatibility, performing well on a wide range of materials including vinyl, textiles, and coated papers, making it ideal for diverse printing applications. Eco-solvent ink excels particularly on coated and uncoated vinyl, banners, and canvas, providing durable prints with excellent outdoor resistance. Your choice depends on the specific substrate requirements, with latex ink delivering flexibility and eco-solvent ink offering specialized adhesion and longevity on select surfaces.

Environmental Impact and Safety

Latex ink contains water-based polymers that produce fewer volatile organic compounds (VOCs) compared to eco-solvent ink, making it a safer choice for indoor air quality and reducing environmental pollution. Eco-solvent ink, while offering durability and vibrant colors, releases higher levels of VOCs and requires proper ventilation and protective measures during use to minimize health risks. The biodegradability of latex ink and its lower hazardous waste generation contribute to its overall environmentally friendly profile, whereas eco-solvent ink disposal must be managed carefully to avoid soil and water contamination.

Durability and Outdoor Performance

Latex ink offers excellent durability with UV and scratch resistance, making it suitable for outdoor applications exposed to harsh weather conditions. Eco-solvent ink provides strong color vibrancy and water resistance but may require lamination for extended outdoor use to prevent fading and damage. Overall, latex ink outperforms eco-solvent ink in long-term outdoor performance due to its superior resistance to environmental factors.

Drying Time and Production Efficiency

Latex ink features rapid drying times due to its water-based formulation, enabling immediate handling and faster production cycles. Eco-solvent ink, while offering superior print durability, requires longer drying periods that can slow down workflow and reduce overall production efficiency. Choosing latex ink can enhance Your output speed and support high-volume printing demands with minimal downtime.

Maintenance Requirements

Latex ink requires minimal maintenance due to its water-based formula, which reduces nozzle clogging and simplifies cleaning procedures. Eco-solvent ink demands more frequent printhead cleaning and careful handling to prevent clogging caused by its solvent-based composition. Your choice impacts the time and effort spent on routine upkeep, with latex ink offering a more user-friendly maintenance experience.

Cost Comparison and Return on Investment

Latex ink typically involves higher upfront costs due to specialized printers and ink cartridges but offers long-term savings through faster drying times and lower maintenance expenses, enhancing your return on investment. Eco-solvent ink printers generally have lower initial costs, yet ongoing expenses can accumulate from slower print speeds, frequent cleaning, and solvent disposal requirements. Assessing total cost of ownership and production efficiency is crucial for maximizing profitability between latex and eco-solvent ink solutions.

Best Use Cases and Industry Applications

Latex ink excels in outdoor signage, vehicle wraps, and banners due to its durability, water resistance, and vibrant color output, making it ideal for advertising and retail displays. Eco-solvent ink is preferred for indoor applications like wall graphics, decals, and window clings because of its low odor, environmental friendliness, and compatibility with a variety of substrates such as vinyl and canvas. Your choice depends on specific industry needs: latex is favored in large-format printing for long-lasting outdoor use, while eco-solvent suits detailed indoor graphics requiring eco-conscious production.

Latex ink vs eco-solvent ink Infographic

libmatt.com

libmatt.com