UV ink cures instantly under ultraviolet light, offering vibrant colors and excellent durability ideal for high-quality prints on various surfaces. LED ink, cured with energy-efficient LED lights, provides faster drying times and lower heat emissions, enhancing your print production with reduced environmental impact.

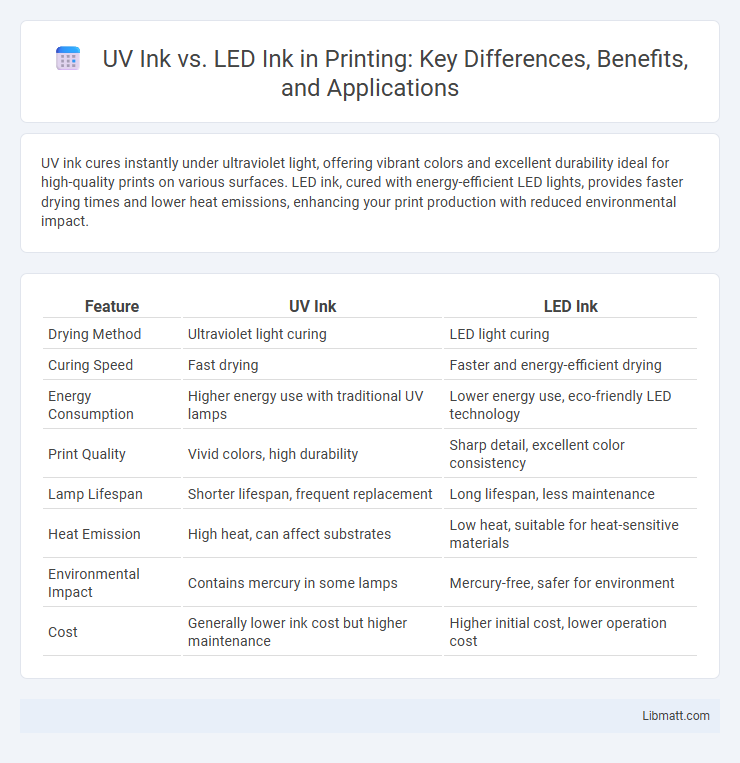

Table of Comparison

| Feature | UV Ink | LED Ink |

|---|---|---|

| Drying Method | Ultraviolet light curing | LED light curing |

| Curing Speed | Fast drying | Faster and energy-efficient drying |

| Energy Consumption | Higher energy use with traditional UV lamps | Lower energy use, eco-friendly LED technology |

| Print Quality | Vivid colors, high durability | Sharp detail, excellent color consistency |

| Lamp Lifespan | Shorter lifespan, frequent replacement | Long lifespan, less maintenance |

| Heat Emission | High heat, can affect substrates | Low heat, suitable for heat-sensitive materials |

| Environmental Impact | Contains mercury in some lamps | Mercury-free, safer for environment |

| Cost | Generally lower ink cost but higher maintenance | Higher initial cost, lower operation cost |

Introduction to UV Ink and LED Ink

UV ink cures instantly when exposed to ultraviolet light, offering vibrant colors, high durability, and resistance to fading, making it ideal for commercial printing and packaging. LED ink, a subtype of UV ink, is formulated specifically to cure under LED light sources, providing energy efficiency, longer lamp life, and lower heat generation compared to traditional UV inks. Both inks enhance print quality and turnaround times but differ primarily in curing technology and environmental impact.

How UV Ink Works

UV ink cures instantly when exposed to ultraviolet light, transforming from a liquid to a solid through a photopolymerization process. This rapid curing allows for high-quality prints with sharp details and vibrant colors on various substrates. You can achieve durable, scratch-resistant results ideal for commercial and industrial applications using UV ink technology.

How LED Ink Works

LED ink cures through exposure to specific wavelengths of LED light, triggering a photoinitiator in the ink to rapidly harden the material. This process generates less heat compared to traditional UV ink curing, reducing substrate damage and energy consumption. LED ink technology supports fast drying times and vibrant color retention, enhancing print durability and environmental sustainability.

Key Differences Between UV Ink and LED Ink

UV ink cures through exposure to ultraviolet light, offering rapid drying times and excellent adhesion on various substrates, while LED ink specifically requires LED light sources, which operate at different wavelengths and typically result in lower energy consumption and longer lamp life. UV ink formulations tend to be broader in compatibility with traditional UV lamps, whereas LED inks are specially designed for LED curing systems, influencing factors such as print durability and environmental impact. Understanding these key differences allows you to choose the optimal ink type for your printing process, balancing efficiency, quality, and cost.

Print Quality Comparison

UV ink offers superior print quality with vibrant colors and sharp details due to its rapid curing process, which prevents ink spread and ensures precise image reproduction. LED ink provides comparable color vibrancy but may exhibit slightly less sharpness on certain substrates because of the lower curing intensity. Choosing the right ink depends on your specific print quality requirements and the materials used.

Curing Process and Technology

UV ink cures through exposure to ultraviolet light, initiating a rapid photochemical reaction that instantly solidifies the ink layer. LED ink utilizes light-emitting diodes emitting specific wavelengths, typically around 395-405 nm, to trigger the curing process with greater energy efficiency and lower heat output. The LED curing technology offers longer-lasting light sources and precise wavelength control, resulting in faster drying times and reduced substrate damage compared to conventional UV curing systems.

Environmental Impact

UV ink and LED ink both offer environmentally friendly printing options due to their low VOC emissions and reduced energy consumption compared to traditional solvent-based inks. LED ink curing requires less energy and produces less heat, minimizing waste and lowering the carbon footprint associated with printing processes. Your choice between UV and LED inks can influence the sustainability of your print projects by reducing harmful emissions and conserving resources.

Cost Analysis: UV Ink vs LED Ink

UV ink generally incurs higher initial equipment costs but offers lower operational expenses due to faster curing times and reduced energy consumption, leading to cost savings over time. LED ink systems, while featuring a higher upfront cost for specialized LEDs, provide longer lamp lifespan and lower maintenance, which can reduce total cost of ownership for your printing operations. Evaluating both ink types requires assessing not only material expense but also energy efficiency, equipment durability, and workflow speed to determine the most cost-effective solution for your needs.

Applications and Industry Uses

UV ink excels in packaging, labels, and promotional products due to its fast curing and vibrant color output, making it ideal for high-quality commercial printing. LED ink is favored in industrial manufacturing and electronics because of its energy efficiency and compatibility with heat-sensitive materials. Both inks serve the automotive sector for durable graphics and the textiles industry for precise, long-lasting prints.

Choosing the Right Ink for Your Needs

UV ink cures instantly under ultraviolet light, offering vibrant colors and excellent adhesion on diverse materials, making it ideal for high-quality, durable prints. LED ink uses energy-efficient light-emitting diodes for curing, providing lower heat output and longer printer lifespan while maintaining color accuracy and quick drying times. Understanding the specifics of your printing environment and material compatibility ensures you select the right ink to optimize print performance and longevity.

UV ink vs LED ink Infographic

libmatt.com

libmatt.com