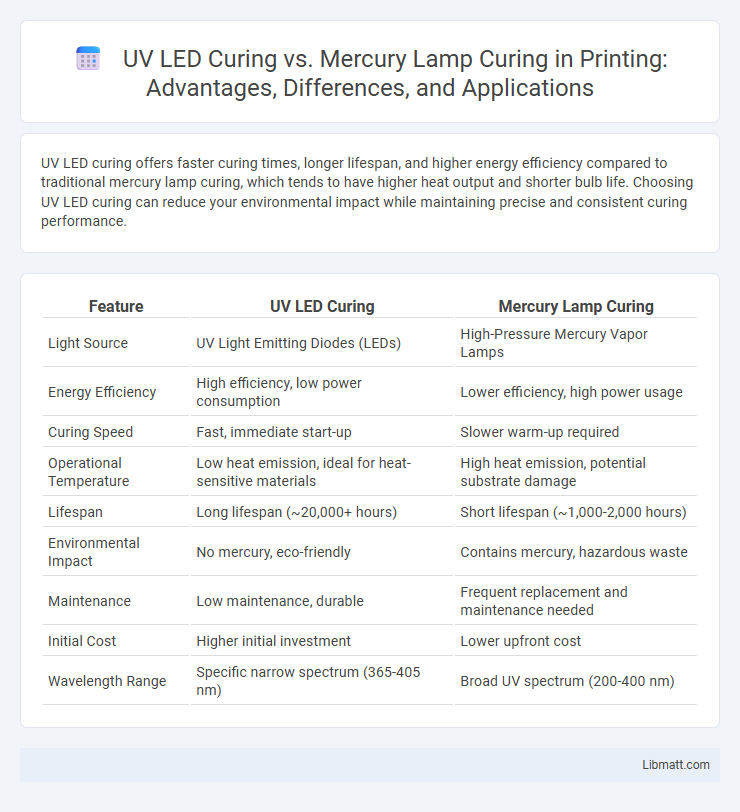

UV LED curing offers faster curing times, longer lifespan, and higher energy efficiency compared to traditional mercury lamp curing, which tends to have higher heat output and shorter bulb life. Choosing UV LED curing can reduce your environmental impact while maintaining precise and consistent curing performance.

Table of Comparison

| Feature | UV LED Curing | Mercury Lamp Curing |

|---|---|---|

| Light Source | UV Light Emitting Diodes (LEDs) | High-Pressure Mercury Vapor Lamps |

| Energy Efficiency | High efficiency, low power consumption | Lower efficiency, high power usage |

| Curing Speed | Fast, immediate start-up | Slower warm-up required |

| Operational Temperature | Low heat emission, ideal for heat-sensitive materials | High heat emission, potential substrate damage |

| Lifespan | Long lifespan (~20,000+ hours) | Short lifespan (~1,000-2,000 hours) |

| Environmental Impact | No mercury, eco-friendly | Contains mercury, hazardous waste |

| Maintenance | Low maintenance, durable | Frequent replacement and maintenance needed |

| Initial Cost | Higher initial investment | Lower upfront cost |

| Wavelength Range | Specific narrow spectrum (365-405 nm) | Broad UV spectrum (200-400 nm) |

Introduction to UV LED and Mercury Lamp Curing

UV LED curing uses light-emitting diodes to emit ultraviolet light, enabling faster curing times and lower energy consumption compared to traditional mercury lamp curing. Mercury lamps generate UV light through an electric arc in mercury vapor, offering broad-spectrum ultraviolet radiation but with higher heat output and shorter lifespan. Understanding these differences helps you choose the optimal curing method for applications in printing, adhesives, and coatings.

Technology Overview: UV LED vs Mercury Lamps

UV LED curing technology uses solid-state diodes that emit specific UV wavelengths, offering instant on/off capabilities and longer lifespan. Mercury lamps generate broad-spectrum UV light through gas discharge, requiring warm-up time and consuming more energy. Your choice impacts curing speed, energy efficiency, and maintenance due to these fundamental technological differences.

Energy Efficiency Comparison

UV LED curing offers significantly higher energy efficiency compared to mercury lamp curing, consuming up to 80% less power while delivering consistent UV output. Mercury lamps generate substantial heat and require warm-up time, leading to wasted energy, whereas UV LED systems operate instantly with minimal heat production. Your choice of UV LED curing can reduce operational costs and environmental impact due to lower energy consumption and longer lamp life.

Curing Speed and Performance

UV LED curing offers significantly faster curing speeds compared to traditional mercury lamp curing, enabling improved productivity in manufacturing processes. The consistent wavelength output of UV LEDs ensures precise and uniform curing performance, enhancing the quality and durability of cured materials. Your operations benefit from lower heat generation and immediate on/off capabilities, which contribute to energy savings and reduced maintenance costs.

Environmental Impact and Safety

UV LED curing significantly reduces environmental impact by eliminating mercury, a hazardous element found in traditional mercury lamps, and lowers energy consumption through higher electrical efficiency. UV LEDs generate minimal heat and emit no ozone, enhancing workplace safety by reducing exposure to toxic substances and thermal risks. The longer lifespan and instant on/off capability of UV LED systems minimize waste and limit harmful emissions compared to the disposal challenges posed by mercury lamps.

Operational Costs and Maintenance

UV LED curing systems offer significantly lower operational costs compared to mercury lamp curing due to their energy efficiency and longer lifespan, often exceeding 20,000 hours versus 1,000 to 2,000 hours for mercury lamps. Maintenance requirements for UV LED systems are minimal, as they generate less heat and do not contain fragile components like mercury lamps, which require frequent replacement and proper disposal. These factors contribute to reduced downtime and lower total cost of ownership in industrial curing applications.

Material Compatibility and Versatility

UV LED curing offers superior material compatibility by emitting a narrow spectrum of UV light, reducing heat stress and enabling safe curing of heat-sensitive and diverse substrates such as plastics, adhesives, and coatings. Mercury lamp curing produces a broad UV spectrum, which can cause substrate damage and limits use with temperature-sensitive materials. The versatility of UV LED systems allows precise control over wavelength and intensity, enhancing curing efficiency for a wider range of materials compared to the less adaptable mercury lamp technology.

Lifespan and Reliability

UV LED curing systems offer a significantly longer lifespan, typically exceeding 20,000 hours, compared to mercury lamp curing, which generally lasts around 1,000 to 2,000 hours. The enhanced reliability of UV LED technology reduces maintenance and replacement frequency, ensuring consistent performance and lower downtime. Your production efficiency benefits from the stable output and immediate start-up capability of UV LED curing, making it a more durable and dependable choice.

Industrial Applications and Use Cases

UV LED curing offers faster processing times and lower energy consumption compared to mercury lamp curing, making it ideal for high-volume industrial applications such as electronics manufacturing and automotive coatings. You benefit from UV LED's longer lifespan and reduced heat output, which enables precise curing on heat-sensitive materials in medical device production and flexible packaging. In contrast, mercury lamp curing remains preferred in industries requiring broad-spectrum UV wavelengths, such as printing and decorative coatings, for its proven efficacy on diverse substrates.

Future Trends in UV Curing Technology

UV LED curing technology is rapidly advancing, offering greater energy efficiency, longer lifespan, and reduced environmental impact compared to traditional mercury lamp curing. Emerging trends include the development of higher-intensity UV LED sources and improved wavelength specificity, enabling faster curing times and enhanced compatibility with diverse substrates. Industry demand for sustainable and cost-effective curing solutions drives ongoing innovation in UV LED systems, positioning them as the preferred choice for future applications in coatings, adhesives, and printing.

UV LED curing vs mercury lamp curing Infographic

libmatt.com

libmatt.com