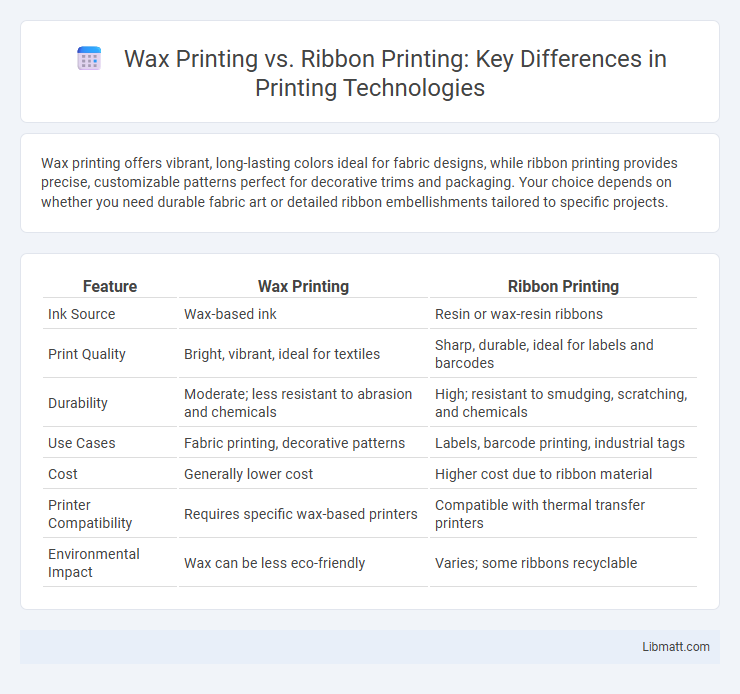

Wax printing offers vibrant, long-lasting colors ideal for fabric designs, while ribbon printing provides precise, customizable patterns perfect for decorative trims and packaging. Your choice depends on whether you need durable fabric art or detailed ribbon embellishments tailored to specific projects.

Table of Comparison

| Feature | Wax Printing | Ribbon Printing |

|---|---|---|

| Ink Source | Wax-based ink | Resin or wax-resin ribbons |

| Print Quality | Bright, vibrant, ideal for textiles | Sharp, durable, ideal for labels and barcodes |

| Durability | Moderate; less resistant to abrasion and chemicals | High; resistant to smudging, scratching, and chemicals |

| Use Cases | Fabric printing, decorative patterns | Labels, barcode printing, industrial tags |

| Cost | Generally lower cost | Higher cost due to ribbon material |

| Printer Compatibility | Requires specific wax-based printers | Compatible with thermal transfer printers |

| Environmental Impact | Wax can be less eco-friendly | Varies; some ribbons recyclable |

Introduction to Wax Printing and Ribbon Printing

Wax printing uses molten wax applied to fabric to create vibrant, intricate designs, ideal for traditional and contemporary textiles. Ribbon printing involves transferring dye or ink onto narrow fabric strips, often used for labels, trims, or decorative accents. Understanding these distinct techniques helps you choose the best method for your custom fabric projects.

Core Principles of Wax Printing

Wax printing utilizes a resist-dyeing technique where melted wax creates patterns on fabric, preventing dye from penetrating those areas and resulting in vibrant, multi-colored designs. This method depends on the precise application of wax, which solidifies and acts as a protective barrier during the dyeing process. The core principle lies in the interplay between wax as a dye inhibitor and fabric absorption, producing intricate, durable patterns distinctive to wax prints.

Core Principles of Ribbon Printing

Ribbon printing utilizes a thermal transfer process where heat from the printhead melts ink from a ribbon, transferring it onto the substrate for sharp and durable images. This method ensures high precision and vibrant color reproduction, particularly on various materials such as textiles, plastics, and paper. The core principle relies on controlled heat application and ribbon composition to achieve consistent, high-quality prints with superior resistance to smudging and fading compared to wax printing.

Material Compatibility: Wax vs. Ribbon

Wax printing excels with natural fabrics such as cotton and silk, where the wax adheres well and creates vibrant, long-lasting colors. Ribbon printing, on the other hand, is more versatile with synthetic materials like polyester, allowing for sharp designs without cracking or peeling. Understanding the material compatibility helps you choose the best printing method to enhance durability and visual appeal.

Print Quality Comparison

Wax printing delivers vibrant colors with sharp edges and smooth gradients, making it ideal for high-resolution textile designs, while ribbon printing often produces less detailed images with visible banding due to limited ink saturation. The durability of wax prints is superior, resisting fading and cracking over time compared to ribbon prints, which can degrade faster under frequent washing or exposure to sunlight. Overall, wax printing provides higher print quality and longevity, especially for fabrics demanding intricate patterns and vivid color retention.

Durability and Resistance Factors

Wax printing offers superior durability due to its thick, wax-based ink that resists cracking and fading over time, making it ideal for textiles exposed to frequent washing and heavy use. Ribbon printing, while providing sharp and vibrant designs, tends to be less resistant to abrasion and may wear off more quickly under constant friction or harsh environmental conditions. Your choice depends on the need for long-lasting, resilient prints versus detailed, vibrant visuals.

Cost Analysis: Wax Printing vs. Ribbon Printing

Wax printing generally incurs lower upfront costs due to cheaper printing materials and simpler equipment, making it ideal for budget-conscious projects. Ribbon printing, while more expensive initially because of specialized ribbons and thermal transfer printers, offers superior durability and color vibrancy, potentially reducing long-term replacement expenses. Your choice should weigh immediate budget constraints against expected print longevity and quality needs.

Typical Applications and Industries

Wax printing dominates textile industries for vibrant and durable fabric designs, commonly used in African clothing, home decor, and fashion apparel. Ribbon printing excels in branding and promotional sectors, ideal for custom packaging, event decorations, and corporate giveaways due to its precision and versatility. Both printing methods serve niche markets, with wax printing favored for traditional textiles and ribbon printing preferred for personalized, small-scale print projects.

Environmental Impact and Sustainability

Wax printing generates less waste as it uses biodegradable wax and natural dyes, making it a more environmentally friendly option compared to ribbon printing, which often relies on synthetic ribbons that contribute to plastic pollution. The sustainability of wax printing is enhanced by its use of renewable materials and minimal energy consumption during production. Your choice of wax printing supports eco-conscious practices by reducing harmful chemicals and promoting recyclable components.

Choosing the Right Printing Method

Wax printing offers vibrant, durable designs ideal for textile applications requiring bold colors and long-lasting patterns, while ribbon printing excels in producing intricate, sharp details on narrow, flexible materials often used for labels and decorative trims. Selecting the right printing method depends on the project's material type, desired print quality, and application purpose, with wax printing favoring fabric-heavy tasks and ribbon printing suited for fine detail on ribbons. Cost efficiency and production volume also influence the choice, as wax printing may be more economical for bulk textile prints, whereas ribbon printing supports customized, small-scale decorative runs.

Wax printing vs ribbon printing Infographic

libmatt.com

libmatt.com