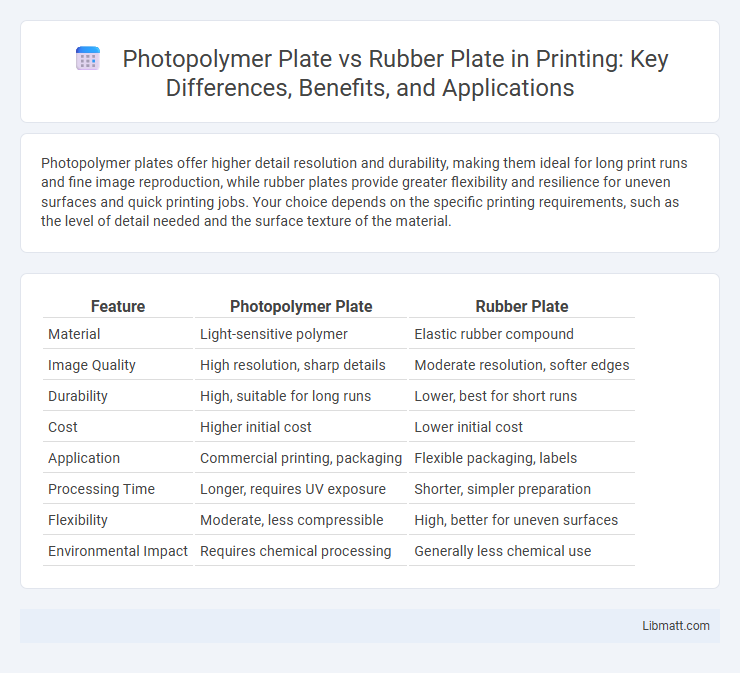

Photopolymer plates offer higher detail resolution and durability, making them ideal for long print runs and fine image reproduction, while rubber plates provide greater flexibility and resilience for uneven surfaces and quick printing jobs. Your choice depends on the specific printing requirements, such as the level of detail needed and the surface texture of the material.

Table of Comparison

| Feature | Photopolymer Plate | Rubber Plate |

|---|---|---|

| Material | Light-sensitive polymer | Elastic rubber compound |

| Image Quality | High resolution, sharp details | Moderate resolution, softer edges |

| Durability | High, suitable for long runs | Lower, best for short runs |

| Cost | Higher initial cost | Lower initial cost |

| Application | Commercial printing, packaging | Flexible packaging, labels |

| Processing Time | Longer, requires UV exposure | Shorter, simpler preparation |

| Flexibility | Moderate, less compressible | High, better for uneven surfaces |

| Environmental Impact | Requires chemical processing | Generally less chemical use |

Introduction to Photopolymer and Rubber Plates

Photopolymer plates are made from light-sensitive polymers that harden when exposed to UV light, enabling high-resolution image reproduction ideal for flexographic printing. Rubber plates consist of natural or synthetic rubber materials known for their durability and ability to print on rough or uneven surfaces, making them suitable for packaging and corrugated substrate applications. Both plate types serve distinct printing needs, with photopolymer plates favored for fine detail and rubber plates preferred for versatility and toughness.

Material Composition and Properties

Photopolymer plates consist of light-sensitive polymers that harden upon UV exposure, offering high-resolution image reproduction and excellent durability for long print runs. Rubber plates are made from natural or synthetic rubber, providing superior flexibility, chemical resistance, and suitability for textured or irregular surfaces. Your choice depends on the printing application, with photopolymer plates delivering precision and rubber plates excelling in versatility and resilience.

Production Process Overview

Photopolymer plates are produced through a digital exposure process where UV light hardens specific areas of the polymer, creating precise, high-resolution image plates ideal for detailed printing. Rubber plates are manufactured by molding or casting natural or synthetic rubber materials, offering flexibility and durability for various printing applications but with less fine detail compared to photopolymer. Your choice between these depends on the desired print quality and production requirements.

Image Reproduction Quality

Photopolymer plates deliver superior image reproduction quality with finer detail and higher resolution, making them ideal for intricate printing tasks. Rubber plates, while more durable and flexible, tend to produce less sharp images due to their softer surface, which can cause slight image distortion. Choosing photopolymer plates enhances your print clarity and precision, especially for high-quality graphic and text reproduction.

Durability and Lifespan

Photopolymer plates offer superior durability and a longer lifespan compared to rubber plates due to their enhanced resistance to abrasion, chemical exposure, and repeated press runs. Rubber plates, while flexible and cost-effective, wear out faster under high-pressure or high-volume printing conditions, resulting in frequent replacements. The durability of photopolymer plates makes them ideal for large-scale commercial printing where consistent quality and extended usage are crucial.

Cost Comparison

Photopolymer plates generally have a higher upfront cost due to advanced materials and technology, but they offer longer durability and consistent print quality, which reduces overall production expenses. Rubber plates are typically more affordable initially but tend to wear out faster, leading to increased replacement costs and potential downtime. Your choice should balance immediate budget constraints with long-term operational efficiency and maintenance expenses.

Environmental Impact

Photopolymer plates generate less waste and have reduced chemical runoff compared to rubber plates, making them more environmentally friendly for printing processes. Their longer lifespan and ability to be recycled minimize resource consumption and landfill contributions. Choosing photopolymer plates for your printing needs supports sustainable practices by lowering the ecological footprint associated with plate production and disposal.

Compatibility with Printing Inks

Photopolymer plates exhibit superior compatibility with a broad range of printing inks, including UV, solvent-based, and water-based inks, due to their chemical resistance and ink-repelling surface properties. In contrast, rubber plates are more suitable for oil-based and conventional inks but may absorb some solvents, affecting print quality over time. Selecting the appropriate plate depends on the printing ink's formulation and the desired print durability and clarity.

Application Suitability

Photopolymer plates offer superior resolution and are ideal for detailed printing applications such as packaging and flexographic labeling, where precision and fine tonal reproduction are critical. Rubber plates excel in applications requiring durability and resistance to abrasive inks, making them suitable for printing on rough or uneven surfaces like corrugated boxes and multi-substrate materials. Both plate types cater to specific industry needs, with photopolymers favored for high-quality graphics and rubber plates preferred for heavy-duty, long-run printing tasks.

Choosing the Right Plate for Your Print Job

Selecting between a photopolymer plate and a rubber plate depends on the specific print job needs, with photopolymer plates offering higher image resolution and better durability for detailed work and long runs. Rubber plates provide greater flexibility and are ideal for printing on uneven or textured surfaces, making them excellent for packaging and label printing. Understanding the substrate, print run length, and desired print quality is crucial to optimize performance and cost-effectiveness.

photopolymer plate vs rubber plate Infographic

libmatt.com

libmatt.com