Make-ready time refers to the preparation period required before starting a production run, including tasks like machine setup and material arrangement. Run time is the actual duration spent producing the items once the setup is complete, directly impacting your overall manufacturing efficiency.

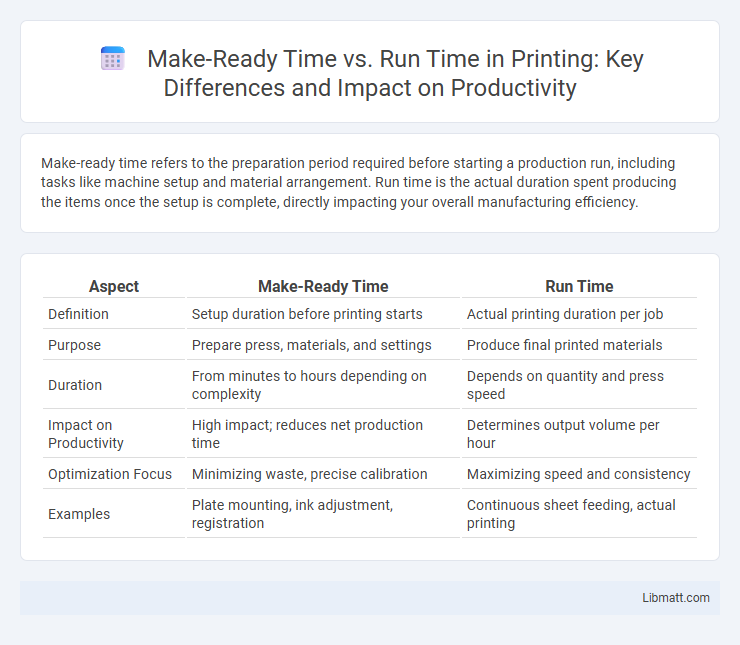

Table of Comparison

| Aspect | Make-Ready Time | Run Time |

|---|---|---|

| Definition | Setup duration before printing starts | Actual printing duration per job |

| Purpose | Prepare press, materials, and settings | Produce final printed materials |

| Duration | From minutes to hours depending on complexity | Depends on quantity and press speed |

| Impact on Productivity | High impact; reduces net production time | Determines output volume per hour |

| Optimization Focus | Minimizing waste, precise calibration | Maximizing speed and consistency |

| Examples | Plate mounting, ink adjustment, registration | Continuous sheet feeding, actual printing |

Understanding Make-Ready Time in Manufacturing

Make-ready time in manufacturing refers to the period required to prepare equipment and processes before production begins, including setup, calibration, and tool changes. This time directly impacts overall operational efficiency by dictating how quickly a machine can transition from idle to productive run time. Reducing make-ready time through streamlined workflows and standardized procedures enhances production capacity and minimizes downtime.

Defining Run Time: What It Means for Production

Run time refers to the actual duration your equipment operates to manufacture products, excluding preparation or downtime. This period directly impacts production output and efficiency, making it crucial for calculating throughput and meeting deadlines. Optimizing run time can reduce costs and improve overall manufacturing performance.

Key Differences Between Make-Ready Time and Run Time

Make-ready time refers to the preparation period required before production begins, involving tasks such as machine setup, calibration, and material loading. Run time is the duration during which actual production occurs, with machines actively processing materials to produce finished goods. Key differences include make-ready time being non-productive and setup-focused, while run time directly contributes to output and efficiency metrics.

The Impact of Make-Ready Time on Production Efficiency

Make-ready time, the period required to prepare equipment or machinery before production begins, significantly affects overall production efficiency by reducing available run time, the duration in which actual manufacturing occurs. Minimizing make-ready time through streamlined setup procedures and advanced automation directly enhances production throughput and decreases downtime. Efficient management of make-ready activities ensures maximum utilization of run time, leading to higher output and cost-effectiveness in manufacturing operations.

Measuring and Reducing Make-Ready Time

Measuring make-ready time involves tracking the duration required to prepare equipment or processes before actual production begins, providing insights into workflow efficiency. Reducing make-ready time often includes streamlining setup procedures, standardizing tasks, and implementing lean manufacturing principles to minimize downtime. Optimizing your manufacturing system by focusing on make-ready time directly enhances run time productivity and overall operational efficiency.

Maximizing Productivity During Run Time

Minimizing make-ready time directly enhances your ability to maximize productivity during run time by increasing the available operational hours for actual production. Efficient setups and quick transitions reduce downtime, allowing continuous workflow and higher output rates. Streamlining make-ready processes ensures that your equipment spends more time producing rather than idling, optimizing overall manufacturing efficiency.

Strategies to Balance Make-Ready and Run Time

Efficient scheduling and equipment maintenance are key strategies to balance make-ready time and run time, ensuring minimal downtime and maximizing production output. Implementing standardized setup procedures and investing in automation can reduce make-ready time without compromising run time efficiency. Your ability to monitor real-time data and adjust workflows accordingly enhances overall operational productivity.

Cost Implications: Make-Ready Time vs Run Time

Make-ready time directly impacts production costs by increasing labor and equipment idle expenses before actual manufacturing begins. Run time affects overall operational efficiency, with longer run times typically driving higher material usage and energy consumption costs. Balancing make-ready time and run time is crucial for minimizing total production expenses and optimizing cost-effectiveness in manufacturing processes.

Industry Examples: Managing Setup and Operation Times

In manufacturing industries such as automotive and electronics, minimizing make-ready time is crucial to boosting overall productivity by reducing machine idle periods during setup. Efficient run time management, especially in fast-paced sectors like packaging and textiles, maximizes output while maintaining quality standards. Companies implement lean manufacturing techniques and advanced scheduling software to balance setup and operation times, enhancing throughput and reducing production costs.

Optimizing Workflow: Best Practices for Make-Ready and Run Time

Optimizing workflow involves minimizing make-ready time by standardizing setup procedures and utilizing advanced scheduling software to reduce delays. Efficient management of run time focuses on maintaining consistent production speeds and immediate troubleshooting to prevent downtime. Maximizing your overall operational efficiency requires balancing these elements to ensure seamless transitions between jobs and sustained productivity.

make-ready time vs run time Infographic

libmatt.com

libmatt.com