High opacity white paint provides a denser, more solid coverage that effectively hides underlying surfaces, making it ideal for projects requiring a crisp, bright finish. Standard white offers a more translucent effect, allowing some texture and color beneath to subtly show through, which can enhance depth in your designs.

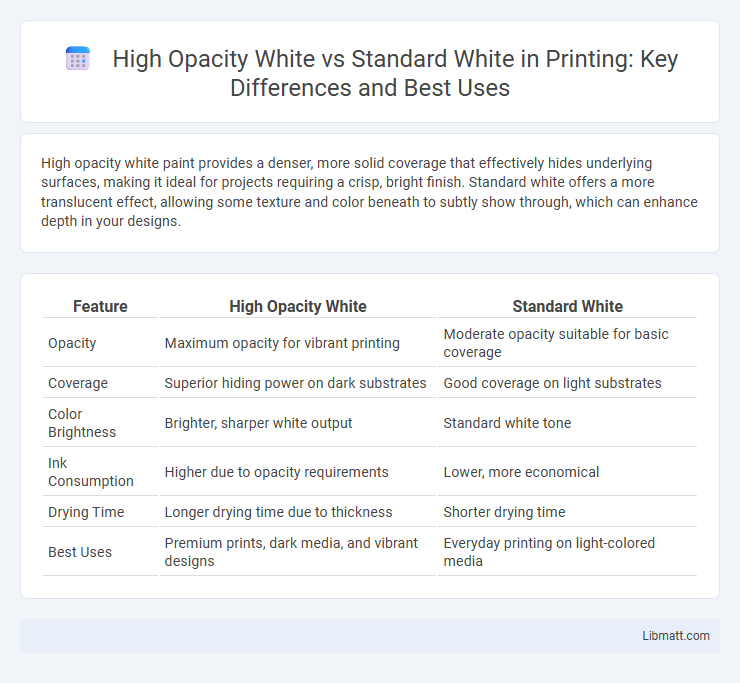

Table of Comparison

| Feature | High Opacity White | Standard White |

|---|---|---|

| Opacity | Maximum opacity for vibrant printing | Moderate opacity suitable for basic coverage |

| Coverage | Superior hiding power on dark substrates | Good coverage on light substrates |

| Color Brightness | Brighter, sharper white output | Standard white tone |

| Ink Consumption | Higher due to opacity requirements | Lower, more economical |

| Drying Time | Longer drying time due to thickness | Shorter drying time |

| Best Uses | Premium prints, dark media, and vibrant designs | Everyday printing on light-colored media |

Introduction to White Printing Inks

High opacity white printing inks deliver superior coverage and brightness by effectively masking underlying colors and surfaces, making them ideal for vibrant designs on both dark and transparent materials. Standard white inks provide moderate opacity, suitable for lighter-colored substrates where less coverage is needed to achieve clean prints. Understanding the difference helps you select the right white ink for sharp, vivid prints that meet your project's visual impact requirements.

What is High Opacity White?

High Opacity White is a specialized ink designed to provide superior coverage and brightness compared to standard white ink, making it ideal for printing on dark or transparent surfaces. It features a higher pigment concentration, resulting in a more solid and opaque finish that prevents underlying colors or backgrounds from showing through. Commonly used in screen printing and digital printing, High Opacity White enhances the vibrancy and durability of printed designs.

Defining Standard White Ink

Standard white ink is commonly used in printing to provide a basic opaque white layer, ensuring colors printed on top appear vibrant and true to their design. High opacity white ink contains a greater concentration of titanium dioxide pigments, resulting in a denser, more solid white that effectively covers dark or colored substrates. This enhanced opacity makes high opacity white ink ideal for applications requiring a crisp, bright white background or high contrast printing on various materials.

Key Differences Between High Opacity and Standard White

High opacity white paint offers superior coverage and hides underlying surfaces more effectively than standard white, making it ideal for projects requiring intense color vibrancy and uniformity. Standard white typically provides a lighter, more translucent finish that may require multiple coats to achieve the same level of opacity. The key difference lies in pigment concentration, with high opacity whites containing higher pigment levels for enhanced durability and coverage.

Applications of High Opacity White

High opacity white is essential for applications requiring superior coverage on dark or colored surfaces, such as labeling, packaging, and signage where vivid contrast and readability are critical. Its enhanced pigment density ensures durability and resistance to fading, making it ideal for industrial printing, textiles, and automotive finishes. Your projects benefit from high opacity white when premium visual impact and long-lasting performance are priorities.

Optimal Uses for Standard White

Standard white offers excellent translucency, making it ideal for applications requiring a balance of brightness and subtlety, such as crafting, printing, and lightweight packaging. Its moderate opacity allows for layering effects and vibrant color overlays without obscuring underlying materials. You can rely on standard white for projects that benefit from a clean, crisp appearance while maintaining some transparency.

Print Quality Comparison

High opacity white ink provides superior print quality by delivering denser coverage and better hiding power compared to standard white, ensuring vibrant and more consistent colors on dark or colored substrates. This enhanced opacity minimizes background show-through and improves color contrast, resulting in sharper, more vivid prints. Standard white ink may appear translucent and less uniform, often requiring multiple layers to achieve similar effects, which can increase production time and costs.

Cost Considerations

High opacity white paint generally costs more than standard white due to its specialized pigments and enhanced coverage properties that reduce the number of coats needed. While the initial investment is higher, high opacity white can save you money in the long run by minimizing paint consumption and labor costs. Choosing between the two depends on your budget and the importance of efficiency in your project.

Choosing the Right White Ink for Your Project

High opacity white ink offers superior coverage on dark or non-porous materials, ensuring vibrant, solid designs without underlying color bleed-through. Standard white ink provides adequate translucency for lighter backgrounds, making it suitable for projects where slight substrate visibility enhances the design's aesthetic. Selecting between high opacity and standard white depends on substrate color and material type, print method, and desired vibrancy for optimal visual impact.

Final Thoughts: High Opacity White vs Standard White

High opacity white inks deliver superior coverage and brightness compared to standard white, resulting in more vibrant prints on dark or transparent materials. Your choice should align with the substrate and desired print quality, as high opacity white minimizes show-through and provides a more solid, professional finish. Opting for high opacity white enhances durability and sharpness, especially in detailed or layered designs.

high opacity white vs standard white Infographic

libmatt.com

libmatt.com