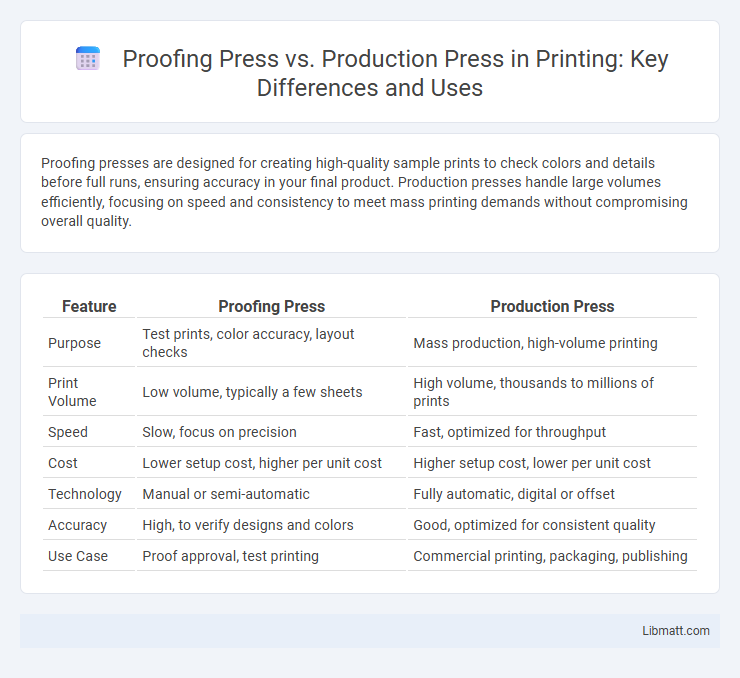

Proofing presses are designed for creating high-quality sample prints to check colors and details before full runs, ensuring accuracy in your final product. Production presses handle large volumes efficiently, focusing on speed and consistency to meet mass printing demands without compromising overall quality.

Table of Comparison

| Feature | Proofing Press | Production Press |

|---|---|---|

| Purpose | Test prints, color accuracy, layout checks | Mass production, high-volume printing |

| Print Volume | Low volume, typically a few sheets | High volume, thousands to millions of prints |

| Speed | Slow, focus on precision | Fast, optimized for throughput |

| Cost | Lower setup cost, higher per unit cost | Higher setup cost, lower per unit cost |

| Technology | Manual or semi-automatic | Fully automatic, digital or offset |

| Accuracy | High, to verify designs and colors | Good, optimized for consistent quality |

| Use Case | Proof approval, test printing | Commercial printing, packaging, publishing |

Introduction to Proofing Press and Production Press

A proofing press is designed for small-scale printing tasks, allowing you to create test prints or limited runs with high accuracy and detail, ensuring color and layout precision before mass production. A production press, on the other hand, is optimized for large-volume printing, offering faster speeds and greater efficiency to handle extensive print jobs with consistent quality. Understanding the differences between proofing and production presses helps you choose the right equipment for your specific printing needs and workflow requirements.

Key Differences Between Proofing and Production Presses

Proofing presses provide high-quality, small-batch prints for color accuracy verification and design evaluation, ensuring your final product meets standards before large-scale production. Production presses prioritize speed, volume, and cost-efficiency, handling continuous runs with consistent output for mass distribution. Key differences between proofing and production presses involve print volume, turnaround time, and precision in color matching.

Core Functions of Proofing Presses

Proofing presses serve the core function of producing high-quality test prints to evaluate color accuracy, layout, and image registration before full-scale production. They enable precise calibration and adjustments on a smaller scale to ensure that the final print run meets design specifications and reduces costly errors. Your use of proofing presses ultimately streamlines the production process by validating artwork under controlled conditions prior to committing to large quantities.

Main Purposes of Production Presses

Production presses are designed for high-volume printing tasks, delivering consistent quality and speed to meet large-scale commercial demands. Their main purposes include mass-producing brochures, magazines, packaging materials, and direct mail campaigns efficiently. Your business benefits from these presses by achieving faster turnaround times and maintaining uniform print quality across extensive runs.

Print Quality: Proofing vs. Production

Print quality in proofing presses is optimized for accuracy and color fidelity, simulating the final production output but on a smaller scale to detect errors early. Production presses deliver high-volume printing with consistent, robust output, prioritizing speed and efficiency while maintaining established quality standards. The proofing phase minimizes costly mistakes by ensuring the color calibration and image sharpness meet specifications before full-scale production begins.

Workflow Integration: Proofing and Production Presses

Proofing presses are designed for quick turnaround and color accuracy, enabling seamless workflow integration by providing accurate previews before full-scale production. Production presses excel in high-volume efficiency and consistent output, ensuring smooth integration into large-scale workflows for mass printing needs. Your print process benefits from combining a proofing press for precision checks with production presses for scalable, reliable outputs.

Cost Considerations

Proofing presses typically have lower initial costs and maintenance expenses compared to production presses, making them ideal for small-scale or prototype printing jobs. Production presses demand higher upfront investment and operational costs but offer greater efficiency and volume capacity, reducing per-unit costs over large print runs. Your choice depends on balancing budget constraints with the required print volume and quality precision.

Typical Applications and Use Cases

Proofing presses are primarily used for creating test prints and color proofs to evaluate design accuracy and color fidelity before mass production. Production presses are designed for high-volume printing jobs, ensuring consistent quality and efficiency for large-scale commercial printing such as packaging, brochures, and publications. Your choice depends on whether you require precise pre-press verification or efficient large-run production output.

Choosing the Right Press for Your Needs

Selecting between a proofing press and a production press depends on your printing volume and quality requirements. Proofing presses offer precise, small-batch prints ideal for testing and fine-tuning designs before full-scale production. Production presses maximize efficiency and speed for large runs, ensuring consistent output and cost-effective mass printing tailored to your business demands.

Future Trends in Press Technology

Future trends in press technology emphasize enhanced automation, digital integration, and sustainability in both proofing presses and production presses. Proofing presses are evolving to provide more accurate color matching and real-time adjustments using AI, ensuring precision before large-scale production. Your printing operations can benefit from production presses adopting advanced robotics and eco-friendly inks, increasing efficiency while reducing environmental impact.

Proofing press vs production press Infographic

libmatt.com

libmatt.com