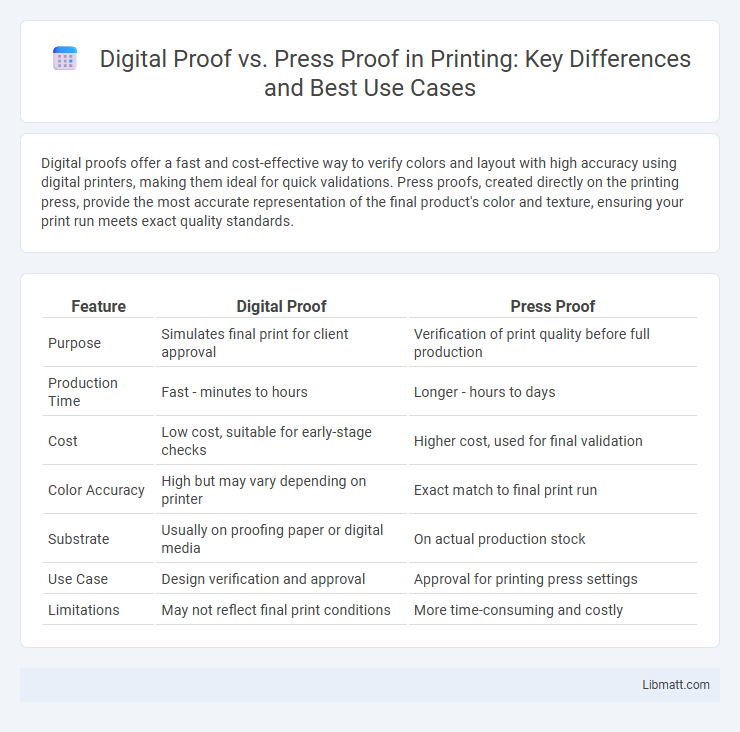

Digital proofs offer a fast and cost-effective way to verify colors and layout with high accuracy using digital printers, making them ideal for quick validations. Press proofs, created directly on the printing press, provide the most accurate representation of the final product's color and texture, ensuring your print run meets exact quality standards.

Table of Comparison

| Feature | Digital Proof | Press Proof |

|---|---|---|

| Purpose | Simulates final print for client approval | Verification of print quality before full production |

| Production Time | Fast - minutes to hours | Longer - hours to days |

| Cost | Low cost, suitable for early-stage checks | Higher cost, used for final validation |

| Color Accuracy | High but may vary depending on printer | Exact match to final print run |

| Substrate | Usually on proofing paper or digital media | On actual production stock |

| Use Case | Design verification and approval | Approval for printing press settings |

| Limitations | May not reflect final print conditions | More time-consuming and costly |

Introduction to Digital Proof and Press Proof

Digital proof is a preliminary version of a print job generated using digital printing technology, allowing for accurate color and layout verification before mass production. Press proof, produced directly on the printing press, serves as a final quality check, reflecting exact color, paper, and print conditions of the press run. Both proofs play crucial roles in ensuring print accuracy and consistency, with digital proofs offering speed and flexibility, and press proofs providing precise physical output validation.

Understanding Digital Proof: Key Features

Digital proof offers a precise, cost-effective method for verifying color accuracy and layout before mass printing, utilizing high-resolution inkjet or laser printers to simulate final output. Key features include rapid turnaround times, easy adjustments, and the ability to produce proofs on a variety of substrates, closely mimicking the end product. Your production process benefits from early detection of errors, ensuring consistency and reducing expensive reprints compared to traditional press proofs.

What is Press Proof? Core Characteristics

Press Proof is a high-fidelity, physical sample produced directly from printing press plates to accurately represent the final print run. It features precise color matching, paper type, and finishing techniques specific to the actual press used, ensuring your review reflects true production quality. This proofing method is essential for identifying potential errors and color discrepancies before large-scale printing begins.

Digital Proof vs Press Proof: Major Differences

Digital proof uses digital printing technology to create a quick, cost-effective sample that accurately represents colors and layout, while press proof is produced using the actual printing press for precise color matching and quality verification. Digital proofs are ideal for initial stages and client approvals, offering faster turnaround and lower costs, whereas press proofs ensure fidelity for final production by simulating the exact press conditions. Understanding these major differences helps optimize workflow efficiency and guarantee print accuracy in professional printing projects.

Cost Comparison: Digital vs Press Proof

Digital proof offers significant cost savings compared to press proof by eliminating the need for physical plates and extensive setup processes, making it ideal for small print runs or frequent revisions. Press proof involves higher expenses due to plate creation, press setup, and waste of materials, which increase overall production costs especially for large-scale projects. You can reduce proofing costs efficiently by opting for digital proofs that provide quicker turnaround times without compromising on accuracy.

Accuracy and Color Reproduction

Digital proof offers high accuracy and color reproduction by using inkjet or laser printers calibrated to specific color profiles, allowing precise simulation of final print colors. Press proof, produced directly on the actual press, ensures the most accurate color match and tonal range by replicating the exact printing conditions and substrates. Although digital proofs provide faster turnaround, press proofs remain the industry standard for final color approval due to superior fidelity and consistency.

Turnaround Time and Flexibility

Digital proofs offer significantly faster turnaround times compared to press proofs, enabling quicker review and approval cycles essential for tight deadlines. Your ability to make last-minute changes is enhanced with digital proofs, as they can be easily updated without the need to reset printing plates. Press proofs, while more accurate for color and print quality confirmation, require longer preparation and are less flexible for rapid adjustments.

Choosing the Right Proofing Method

Choosing the right proofing method depends on your project's accuracy requirements and budget constraints. Digital proof offers fast turnaround and cost-effectiveness with good color accuracy for most print jobs, while press proof provides the most precise representation by simulating the final printed output on the actual press. Your decision should balance the need for color fidelity and material texture against timing and expense to ensure the best print quality.

Common Applications in the Printing Industry

Digital proofs are commonly used for quick, cost-effective content verification and color accuracy checks in packaging design and short-run print jobs, enabling faster turnaround times. Press proofs serve as critical benchmarks for high-volume publications and commercial printing, ensuring precise color matching, resolution, and print quality before full-scale production. Both proofs play integral roles in quality control processes, with digital proofs facilitating early-stage corrections and press proofs validating final print output.

Future Trends in Proofing Technology

Digital proof technology is rapidly advancing with AI-driven color calibration and cloud-based collaboration platforms that enhance speed and accuracy in the prepress workflow. Press proofing remains essential for final validation, but innovations like high-resolution inkjet presses and real-time monitoring systems are narrowing the gap between digital and press outputs. Emerging trends emphasize sustainability and cost-efficiency while maintaining stringent color fidelity standards critical to brand consistency.

Digital Proof vs Press Proof Infographic

libmatt.com

libmatt.com