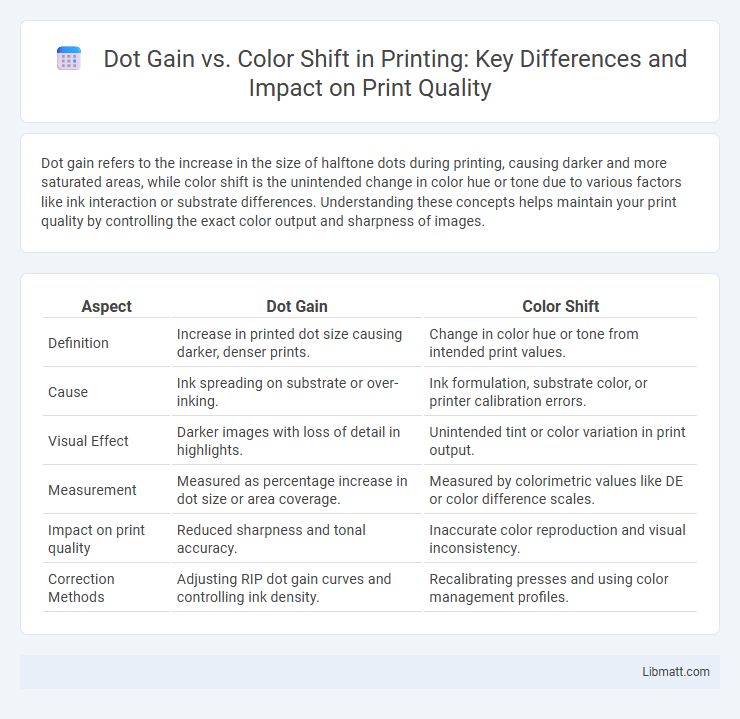

Dot gain refers to the increase in the size of halftone dots during printing, causing darker and more saturated areas, while color shift is the unintended change in color hue or tone due to various factors like ink interaction or substrate differences. Understanding these concepts helps maintain your print quality by controlling the exact color output and sharpness of images.

Table of Comparison

| Aspect | Dot Gain | Color Shift |

|---|---|---|

| Definition | Increase in printed dot size causing darker, denser prints. | Change in color hue or tone from intended print values. |

| Cause | Ink spreading on substrate or over-inking. | Ink formulation, substrate color, or printer calibration errors. |

| Visual Effect | Darker images with loss of detail in highlights. | Unintended tint or color variation in print output. |

| Measurement | Measured as percentage increase in dot size or area coverage. | Measured by colorimetric values like DE or color difference scales. |

| Impact on print quality | Reduced sharpness and tonal accuracy. | Inaccurate color reproduction and visual inconsistency. |

| Correction Methods | Adjusting RIP dot gain curves and controlling ink density. | Recalibrating presses and using color management profiles. |

Understanding Dot Gain: Definition and Causes

Dot gain refers to the increase in size of halftone dots during the printing process, causing printed images to appear darker and less sharp than intended. It occurs due to factors such as ink spread, paper absorption, and press pressure, which affect the final output color density. Understanding dot gain helps you anticipate and adjust for color shifts, ensuring accurate reproduction of your designed colors.

What is Color Shift? Key Concepts Explained

Color shift refers to the unwanted alteration in color appearance during the printing process, often caused by factors like dot gain, ink absorption, or drying inconsistencies. It impacts the accuracy of the final image by changing the intended hues, saturation, or brightness, making precise color management essential. Understanding how dot gain affects color shift helps you control the printing output for consistent and predictable results.

Dot Gain in Different Printing Processes

Dot gain varies significantly across printing processes, with flexography often exhibiting higher dot gain due to its porous substrates and anilox roller characteristics, while offset lithography typically maintains tighter dot gain control thanks to its smoother plates and paper. Digital printing processes like inkjet and laser show minimal dot gain but can experience color shift caused by ink absorption and drying inconsistencies. Understanding your specific printing method is crucial for managing dot gain effects and minimizing unwanted color shifts to ensure accurate color reproduction.

Factors Influencing Color Shift in Printing

Factors influencing color shift in printing include ink absorption rates, paper type, and environmental conditions such as temperature and humidity. Dot gain, which refers to the increase in dot size during printing, plays a crucial role by altering color density and sharpness, thereby causing perceptible shifts in color accuracy. Precise control of press settings and consistent substrate quality are essential to minimize these variations and achieve predictable color outcomes.

Dot Gain vs. Color Shift: Key Differences

Dot gain refers to the increase in the size of halftone dots during printing, causing darker and muddier images. Color shift occurs when hues change unintentionally, affecting the overall color accuracy and vibrancy of your prints. Understanding dot gain versus color shift is essential for optimizing print quality and achieving precise color reproduction.

How Dot Gain Affects Print Color Accuracy

Dot gain directly impacts print color accuracy by causing printed dots to spread beyond their intended size, leading to darker and more saturated colors than expected. This increase in dot size alters ink density and reduces tonal detail, making color reproduction less precise and consistent. Understanding dot gain is crucial for calibrating your printing process to maintain accurate color matching and high-quality output.

Managing Color Shift: Best Practices

Managing color shift effectively requires precise control over dot gain during the printing process, as excessive dot gain can cause unwanted color shifts and muddy image quality. Implementing ICC profiles tailored to your specific press and substrate helps maintain color consistency by compensating for dot gain variations. Regular calibration and consistent monitoring of press conditions ensure your prints stay true to the intended colors, minimizing shifts and enhancing overall visual accuracy.

Measurement Tools for Dot Gain and Color Shift

Measurement tools for dot gain include densitometers and spectrophotometers that analyze print samples by quantifying the dot area coverage versus the intended design, providing precise percentage values of dot gain. Color shift measurement relies on spectrophotometers and colorimeters to detect deviations in color coordinates (such as CIELAB values) between the original digital file and the printed output, ensuring accurate color reproduction. Advanced software solutions integrate these tools, offering comprehensive analysis and real-time monitoring to maintain print quality and consistency.

Preventing Dot Gain and Color Shift in Print Production

Preventing dot gain and color shift in print production involves precise control of ink density and substrate selection to maintain accurate color reproduction. Calibrating your press regularly and using color management systems helps minimize variations caused by environmental conditions and material inconsistencies. Optimizing these factors ensures your prints retain sharpness, vibrancy, and true color fidelity.

Choosing the Right Materials to Minimize Print Issues

Selecting high-quality paper and compatible inks directly impacts dot gain and color shift during printing, ensuring sharper images and accurate color reproduction. Coated papers reduce dot gain by preventing ink spread, while pigment-based inks enhance color stability and minimize shifts over time. Proper material choices tailored to the printing process help maintain consistency and achieve precise, vibrant results.

dot gain vs color shift Infographic

libmatt.com

libmatt.com