An offset blanket is a rubber-covered fabric wrapped around the impression cylinder in offset printing, which transfers ink from the printing plate to paper, ensuring high-quality and consistent image reproduction. Your choice between an offset blanket and impression cylinder hinges on their roles: the blanket acts as the intermediary surface for ink transfer, while the impression cylinder applies pressure to achieve precise contact between the blanket and the substrate.

Table of Comparison

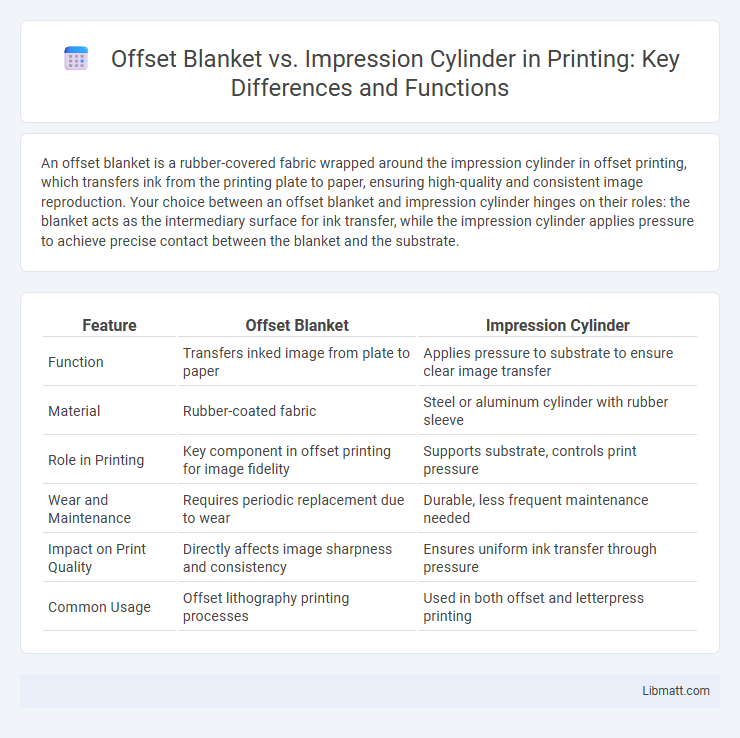

| Feature | Offset Blanket | Impression Cylinder |

|---|---|---|

| Function | Transfers inked image from plate to paper | Applies pressure to substrate to ensure clear image transfer |

| Material | Rubber-coated fabric | Steel or aluminum cylinder with rubber sleeve |

| Role in Printing | Key component in offset printing for image fidelity | Supports substrate, controls print pressure |

| Wear and Maintenance | Requires periodic replacement due to wear | Durable, less frequent maintenance needed |

| Impact on Print Quality | Directly affects image sharpness and consistency | Ensures uniform ink transfer through pressure |

| Common Usage | Offset lithography printing processes | Used in both offset and letterpress printing |

Introduction to Offset Blanket and Impression Cylinder

The offset blanket and impression cylinder are critical components in offset printing, each serving distinct functions that ensure high-quality image transfer. The offset blanket, a rubber-coated fabric wrapped around a cylinder, picks up ink from the plate cylinder and transfers it to the printing substrate with precision. The impression cylinder applies consistent pressure to the substrate, securing accurate contact between the blanket and paper to produce sharp, detailed prints essential for your printing projects.

What is an Offset Blanket?

An offset blanket is a key component in offset printing that transfers ink from the printing plate to the paper. It is made of multiple layers, including a rubber surface that provides flexibility and durability, enabling high-quality image reproduction. Your printing quality depends significantly on the condition and material of the offset blanket, as it ensures accurate and consistent ink distribution during the printing process.

What is an Impression Cylinder?

An impression cylinder is a key component in offset printing that provides precise pressure to transfer ink from the printing plate to the paper, ensuring sharp image quality. It works in tandem with the blanket cylinder, which carries the inked image, by pressing the substrate evenly against the blanket for optimal ink transfer. Understanding the role of the impression cylinder helps you achieve consistent, high-resolution prints in offset printing processes.

Key Functions in Printing Process

The offset blanket transfers ink from the plate to the printing surface by creating a smooth, flexible intermediary layer that ensures even ink distribution and high-quality image reproduction. The impression cylinder applies pressure to the substrate against the offset blanket, securing accurate registration and consistent print sharpness during the printing process. Your choice of offset blanket and impression cylinder directly impacts print clarity, color fidelity, and overall production efficiency.

Materials and Construction Differences

Offset blankets are typically made of multiple layers, including a compressible rubber surface bonded to a fabric or metal backing, providing durability and flexibility for high-quality ink transfer. Impression cylinders are usually constructed from solid metal, often steel or aluminum, designed to withstand significant pressure and maintain precise alignment during printing. Understanding these materials and construction differences can help You choose the right component for optimal printing performance and lifespan.

Print Quality Comparison

Offset blankets provide consistent, high-resolution print quality by evenly transferring ink from the plate to the substrate, minimizing surface imperfections and color variations. Impression cylinders apply uniform pressure during the printing process, which enhances detail sharpness and prevents distortion, crucial for complex graphics and fine text. Your choice between an offset blanket and an impression cylinder will impact the clarity, vibrancy, and overall precision of the final print output.

Durability and Maintenance

Offset blankets demonstrate high durability due to their multi-layered construction, which resists wear and mechanical stress during extended print runs. Impression cylinders, typically made of hardened steel, require minimal maintenance but can suffer from surface wear or damage that affects print quality over time. Proper maintenance routines, such as regular cleaning and timely inspections, are essential for both components to ensure consistent performance and longevity in printing operations.

Cost Implications

Offset blankets typically incur lower replacement costs compared to impression cylinders, making them a more budget-friendly choice for frequent maintenance. Impression cylinders involve higher initial investment and specialized machining, leading to increased overall expenses in press setup and repairs. Businesses must evaluate long-term operational budgets, considering that offset blankets offer cost savings through durability and ease of replacement.

Applications and Suitability

Offset blankets are primarily used in sheetfed and web offset printing, offering excellent ink transfer and image quality on various paper types, making them ideal for high-volume commercial printing and packaging applications. Impression cylinders provide the necessary pressure to ensure precise image transfer from the blanket to the substrate, crucial for maintaining print consistency on delicate or textured materials. The combination of offset blankets and impression cylinders ensures suitability for detailed graphics, fine text, and diverse substrates in newspaper, label, and book printing industries.

Choosing Between Offset Blanket and Impression Cylinder

Choosing between an offset blanket and an impression cylinder depends on the specific printing requirements and substrate type. The offset blanket provides cushioning that improves ink transfer and image quality on uneven surfaces, making it ideal for flexible materials. The impression cylinder applies consistent pressure, essential for precise registration and sharp images, especially on rigid substrates, helping your print project achieve the best results based on material and design complexity.

offset blanket vs impression cylinder Infographic

libmatt.com

libmatt.com