Polyester plates offer excellent chemical resistance and flexibility, making them ideal for applications requiring durability and lightweight materials. Aluminum plates provide superior strength, heat dissipation, and corrosion resistance, making them suitable for heavy-duty uses where structural support is crucial for your projects.

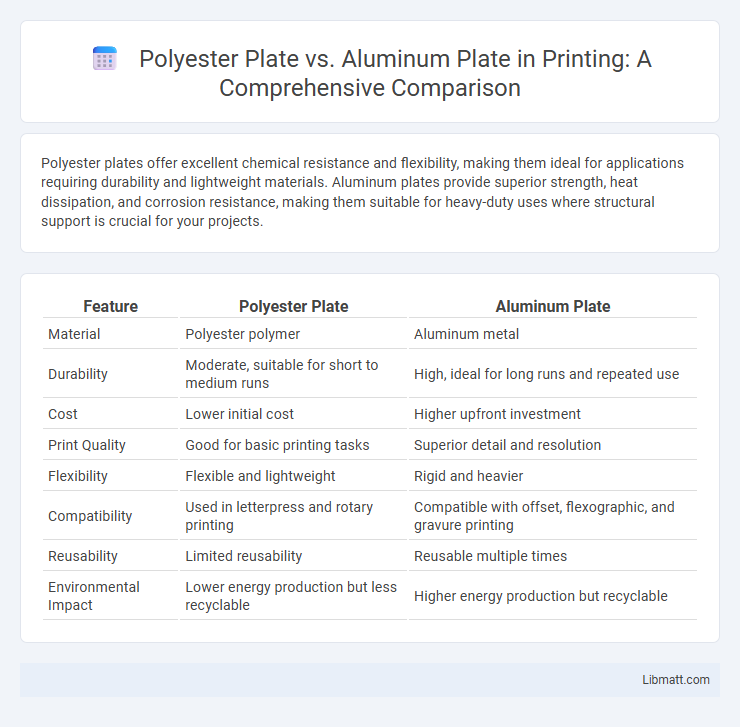

Table of Comparison

| Feature | Polyester Plate | Aluminum Plate |

|---|---|---|

| Material | Polyester polymer | Aluminum metal |

| Durability | Moderate, suitable for short to medium runs | High, ideal for long runs and repeated use |

| Cost | Lower initial cost | Higher upfront investment |

| Print Quality | Good for basic printing tasks | Superior detail and resolution |

| Flexibility | Flexible and lightweight | Rigid and heavier |

| Compatibility | Used in letterpress and rotary printing | Compatible with offset, flexographic, and gravure printing |

| Reusability | Limited reusability | Reusable multiple times |

| Environmental Impact | Lower energy production but less recyclable | Higher energy production but recyclable |

Introduction to Printing Plates

Polyester plates offer lightweight, cost-effective solutions for short-run printing projects with flexible durability, while aluminum plates provide high precision and longevity suitable for high-volume commercial printing. The choice between polyester and aluminum printing plates impacts image quality, plate life, and overall print consistency. Understanding your printing needs helps determine the optimal plate material to maximize efficiency and output quality.

What is a Polyester Plate?

A polyester plate is a durable printing plate made from a synthetic polymer known for its flexibility and resistance to chemicals. This type of plate offers excellent dimensional stability and is commonly used in flexographic printing processes for packaging and labels. Polyester plates provide cost-effective, high-quality printing solutions, making them a suitable choice for your versatile printing needs.

What is an Aluminum Plate?

An aluminum plate is a flat, thick sheet made from aluminum alloy, known for its lightweight, corrosion resistance, and high strength-to-weight ratio. Commonly used in aerospace, automotive, and construction industries, aluminum plates offer excellent durability and heat conductivity compared to polyester plates. Your choice depends on the application's requirements for rigidity, weight, and environmental exposure.

Key Differences Between Polyester and Aluminum Plates

Polyester plates offer lightweight flexibility and resistance to chemicals, making them ideal for printing applications requiring durability and ease of handling, while aluminum plates deliver superior rigidity, heat resistance, and long-term stability suited for high-precision engraving and industrial use. You'll find polyester plates absorb less moisture, reducing distortion, whereas aluminum plates provide enhanced thermal conductivity and durability for demanding mechanical environments. Choosing between polyester and aluminum plates depends on your specific needs for strength, weight, and environmental resistance in your project.

Cost Comparison: Polyester vs Aluminum Plates

Polyester plates generally offer a lower cost compared to aluminum plates, making them an economical choice for budget-sensitive projects. Aluminum plates, while more expensive, provide superior durability and heat resistance, which can result in cost savings over time through longer lifespan and reduced replacement frequency. You should consider both initial investment and long-term value when comparing the cost-effectiveness of polyester versus aluminum plates.

Durability and Longevity

Polyester plates exhibit notable durability due to their resistance to corrosion, moisture, and chemicals, making them ideal for environments with exposure to harsh elements. Aluminum plates offer superior longevity through excellent strength-to-weight ratio, high resistance to corrosion, and ability to withstand extreme temperatures without warping or weakening. Both materials deliver long-term performance, but aluminum plates often provide enhanced structural durability in demanding industrial applications.

Print Quality and Resolution

Polyester plates offer higher print quality and resolution due to their smooth surface, which allows for finer details and sharper images, making them ideal for intricate designs and high-definition printing. Aluminum plates provide excellent durability and heat resistance but may slightly compromise on the ultra-fine resolution compared to polyester plates. Your choice depends on whether you prioritize exceptional detail precision or long-lasting, robust printing performance.

Suitability for Different Printing Applications

Polyester plates excel in flexographic printing due to their flexibility, making them ideal for packaging and label production on various substrates. Aluminum plates offer superior durability and precision, preferred in high-volume offset and gravure printing for detailed image reproduction. Choosing between polyester and aluminum depends on the printing technology, substrate type, and production scale, ensuring optimal print quality and cost-effectiveness.

Environmental Impact and Recycling

Polyester plates have a lower environmental impact due to their lighter weight and energy-efficient production compared to aluminum plates, which require intensive mining and smelting processes that release greenhouse gases. Recycling aluminum plates is highly efficient, with up to 95% of energy saved compared to primary production, whereas polyester plates pose challenges due to limited recycling facilities and the release of microplastics when degraded. The choice between polyester and aluminum plates depends on balancing lightweight sustainability with recycling infrastructure and potential environmental pollutants.

Choosing the Right Plate for Your Print Needs

Polyester plates offer exceptional durability, chemical resistance, and consistent image quality, making them ideal for high-volume flexographic printing with detailed graphics. Aluminum plates provide superior precision, excellent thermal stability, and are preferred for long runs or applications requiring fine lines and sharp images. Selecting the right plate depends on print volume, image detail, substrate compatibility, and budget considerations to ensure optimal performance and cost-efficiency in your printing projects.

Polyester Plate vs Aluminum Plate Infographic

libmatt.com

libmatt.com