Silk screen and mesh screen both refer to materials used in screen printing, with silk screen traditionally made from natural silk and mesh screen typically made from synthetic fibers like polyester offering greater durability and precision. Your choice depends on the level of detail required and the type of ink used, as mesh screens provide finer control for high-resolution prints compared to silk screens.

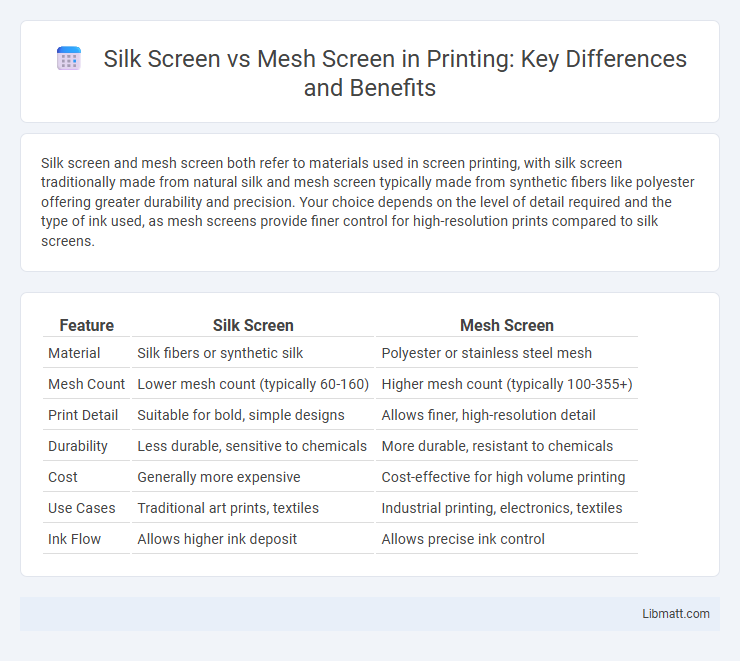

Table of Comparison

| Feature | Silk Screen | Mesh Screen |

|---|---|---|

| Material | Silk fibers or synthetic silk | Polyester or stainless steel mesh |

| Mesh Count | Lower mesh count (typically 60-160) | Higher mesh count (typically 100-355+) |

| Print Detail | Suitable for bold, simple designs | Allows finer, high-resolution detail |

| Durability | Less durable, sensitive to chemicals | More durable, resistant to chemicals |

| Cost | Generally more expensive | Cost-effective for high volume printing |

| Use Cases | Traditional art prints, textiles | Industrial printing, electronics, textiles |

| Ink Flow | Allows higher ink deposit | Allows precise ink control |

Introduction to Silk Screen and Mesh Screen

Silk screen and mesh screen are both essential tools in printing and filtration industries, with silk screen traditionally made from natural fibers and mesh screen typically constructed from synthetic materials like polyester or nylon. Silk screens offer fine texture and high durability, ideal for detailed artwork and precise printing applications, while mesh screens provide versatility in pore size and strength suited for industrial filtration or stenciling tasks. Your choice between silk and mesh screens depends on the required resolution, material strength, and specific application needs.

Defining Silk Screen Printing

Silk screen printing, also known as screen printing, involves pressing ink through a woven mesh stencil to create detailed and vibrant designs on various surfaces. The silk screen mesh determines the ink flow and resolution, with finer meshes producing sharper images. Compared to other mesh screens, silk screen printing provides durability and versatility for textiles, posters, and promotional materials.

Understanding Mesh Screen Technology

Mesh screen technology in silk screen printing uses a woven fabric made from materials like polyester or stainless steel to create a stencil that allows ink to pass through specific areas. The mesh count, indicating the number of threads per inch, directly affects the level of detail and ink deposit, with higher mesh counts producing finer detail and thinner ink layers. Different mesh materials and tensions contribute to durability, print clarity, and suitability for various substrates and ink types in the silk screen process.

Material Differences: Silk Screen vs Mesh Screen

Silk screens are traditionally made from natural silk fibers, providing a finer, smoother surface ideal for detailed, high-resolution printing. Mesh screens, typically constructed from synthetic materials like polyester or nylon, offer greater durability and resistance to wear, making them suitable for industrial and high-volume printing applications. The choice between silk and mesh screens depends on balancing the need for precision with longevity and cost-effectiveness in various printing projects.

Printing Quality Comparison

Silk screen printing typically offers finer detail and higher resolution, producing sharper images due to the thin and consistent silk threads. Mesh screens, often made from synthetic materials like polyester, provide versatile porosity, allowing for better ink flow and vibrant color saturation on various substrates. Overall, silk screens excel in precision, while mesh screens balance detail with durability and speed for diverse printing applications.

Durability and Longevity

Silk screen offers moderate durability but tends to wear out faster under heavy use due to its softer fibers, making it less ideal for long-term applications. Mesh screens, often made from synthetic materials like polyester or nylon, provide superior longevity and resistance to wear, maintaining clarity and structural integrity through repeated usage. Choosing mesh screen ensures your display or filtration system benefits from extended durability and consistent performance over time.

Cost Analysis

Silk screen printing generally incurs higher material costs due to the premium quality silk threads used, which offer superior detail and durability compared to mesh screens made from polyester or nylon. Mesh screens typically present a more cost-effective option, with lower initial investment and maintenance expenses, making them ideal for high-volume, budget-conscious projects. Cost efficiency is further influenced by project scale and intended print quality, with silk screens favored for intricate designs despite their higher upfront costs.

Common Applications

Silk screen is commonly used in printing intricate designs on textiles, posters, and promotional items due to its fine thread count and smooth texture. Mesh screen excels in industrial filtration, window screens, and insect protection because of its durable and breathable material. Your choice depends on whether you prioritize detailed graphic reproduction or functional airflow and protection.

Pros and Cons of Each Method

Silk screen printing offers excellent ink adhesion and vibrant color output, making it ideal for detailed designs, but it tends to be slower and less cost-effective for large runs compared to mesh screen printing. Mesh screen printing enables faster production rates and better ink flow control, suitable for high-volume printing, yet it may sacrifice some image sharpness and is limited with very fine details. Both methods require careful screen maintenance, with silk screens being more delicate and mesh screens more durable but prone to clogging.

Choosing the Right Screen for Your Needs

Selecting between silk screen and mesh screen depends on the printing project's detail and fabric type, where silk screens offer finer resolution ideal for intricate designs on smooth materials, while mesh screens provide durability and higher ink flow suitable for bold graphics on rough surfaces. Mesh count is critical; higher mesh counts yield finer detail but slower ink transfer, whereas lower mesh counts allow faster printing with thicker ink layers, impacting overall print quality. Understanding the material compatibility, design complexity, and production volume will guide you to the optimal screen choice for superior results.

Silk Screen vs Mesh Screen Infographic

libmatt.com

libmatt.com