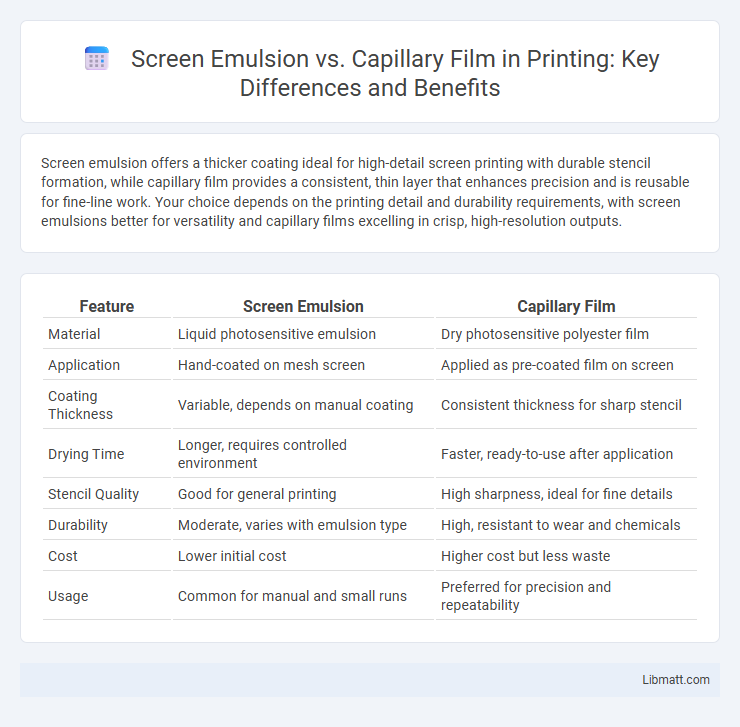

Screen emulsion offers a thicker coating ideal for high-detail screen printing with durable stencil formation, while capillary film provides a consistent, thin layer that enhances precision and is reusable for fine-line work. Your choice depends on the printing detail and durability requirements, with screen emulsions better for versatility and capillary films excelling in crisp, high-resolution outputs.

Table of Comparison

| Feature | Screen Emulsion | Capillary Film |

|---|---|---|

| Material | Liquid photosensitive emulsion | Dry photosensitive polyester film |

| Application | Hand-coated on mesh screen | Applied as pre-coated film on screen |

| Coating Thickness | Variable, depends on manual coating | Consistent thickness for sharp stencil |

| Drying Time | Longer, requires controlled environment | Faster, ready-to-use after application |

| Stencil Quality | Good for general printing | High sharpness, ideal for fine details |

| Durability | Moderate, varies with emulsion type | High, resistant to wear and chemicals |

| Cost | Lower initial cost | Higher cost but less waste |

| Usage | Common for manual and small runs | Preferred for precision and repeatability |

Introduction to Screen Emulsion and Capillary Film

Screen emulsion is a light-sensitive coating applied to mesh screens used in traditional screen printing, enabling precise image transfer by blocking ink in non-image areas. Capillary film consists of pre-coated, dry photopolymer films with uniform thickness, offering enhanced resolution and finer details in screen printing applications. Both materials are essential for stencil creation, but screen emulsion suits thicker, more durable prints while capillary film excels in high-definition, fine-line reproductions.

What is Screen Emulsion?

Screen emulsion is a light-sensitive liquid or gel applied to a mesh screen, used in screen printing to create stencil patterns. It hardens when exposed to UV light, allowing ink to pass through the unexposed areas and transfer the design onto various surfaces. Your choice between screen emulsion and capillary film depends on factors like durability, ease of use, and level of detail required.

What is Capillary Film?

Capillary film is a high-resolution photo-sensitive material used in screen printing to produce precise stencils. It consists of a thin, uniform layer of photosensitive polymer coated on a clear polyester film, enabling finer detail and sharper edges than traditional screen emulsions. This film is ideal for intricate designs and requires lamination or bonding to the mesh before exposure and washing.

Application Processes Compared

Screen emulsion offers flexibility for intricate designs with direct application onto mesh screens, ideal for custom or low-volume printing. Capillary film provides a uniform, precise layer allowing faster setup and consistent print quality, especially suited for high-volume or repeat jobs. Your choice impacts setup speed, detail accuracy, and overall production efficiency in screen printing workflows.

Durability and Detail Reproduction

Screen emulsion offers excellent durability, standing up well to multiple print runs and harsh cleaning processes, making it ideal for long-term use. Capillary film provides superior detail reproduction with its uniform thickness, enabling finer lines and sharper images on screens. Your choice depends on whether you prioritize the longevity of prints or the precision of intricate designs.

Image Quality and Resolution

Screen emulsion offers high image quality with fine detail reproduction, but capillary film provides superior resolution due to its uniform thickness and smoother surface. Capillary film minimizes dot gain and enhances line sharpness, making it ideal for intricate designs and precise graphics. The consistent coating of capillary film ensures clearer and more accurate image edges compared to traditional screen emulsions.

Cost Comparison: Emulsion vs Capillary Film

Screen emulsion generally offers a lower initial cost compared to capillary film due to its liquid form and the ability to coat screens in-house, reducing material expenses. Capillary film incurs higher upfront costs from pre-coated polyester films but provides consistent thickness and greater detail control, which can lower labor and exposure time expenses in large runs. Evaluating total costs involves balancing emulsion's affordability for small batches against capillary film's efficiency and quality benefits for high-volume or intricate screen printing projects.

Common Uses and Ideal Situations

Screen emulsion is commonly used for manual screen printing processes, ideal for detailed and multi-color designs on textiles and promotional materials where flexibility and ease of use are essential. Capillary film excels in high-precision industrial printing, providing consistent thickness and sharp image resolution, making it suitable for electronics, graphic arts, and fine art reproduction. Both materials serve specific applications based on production scale, detail requirement, and substrate type, optimizing print quality and durability.

Pros and Cons: Side-by-Side Comparison

Screen emulsion offers flexibility in custom thickness adjustments and cost-effectiveness for small to medium runs, but it requires longer drying times and can be messy during application. Capillary film provides consistent uniform thickness and faster setup with cleaner application, ideal for high-precision and high-volume printing, though it tends to be more expensive and less adaptable to varying mesh tensions. Both methods impact the final print quality based on the complexity of the design and production scale, making the choice dependent on specific project requirements.

Conclusion: Choosing the Best Method for Your Needs

Screen emulsion offers versatility and ease of use, making it ideal for small to medium production runs with detailed artwork, while capillary film provides sharper image resolution and consistency suited for high-volume commercial printing. Your decision should consider factors such as production scale, image detail, and budget constraints to maximize efficiency and print quality. Selecting the best method ultimately depends on aligning these key parameters with your specific printing requirements.

screen emulsion vs capillary film Infographic

libmatt.com

libmatt.com