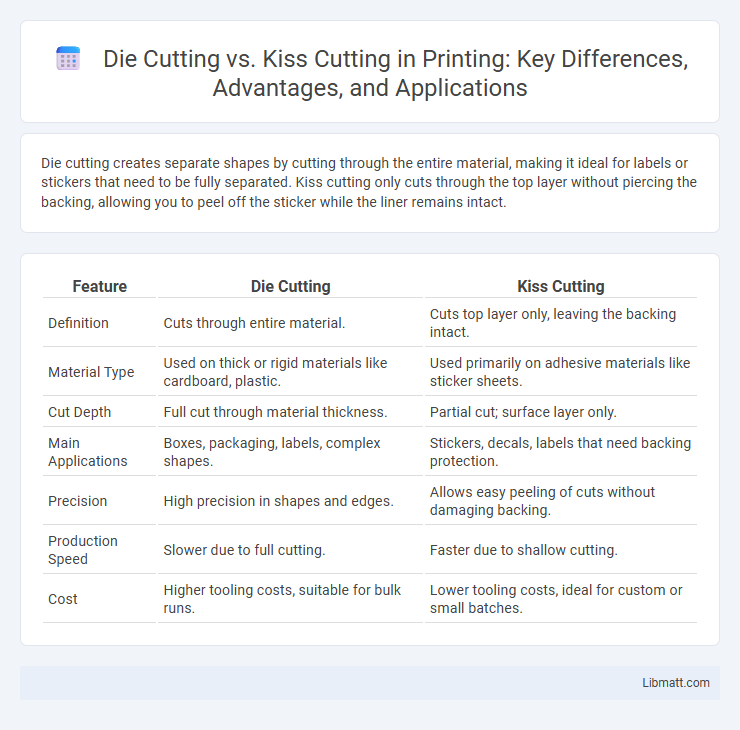

Die cutting creates separate shapes by cutting through the entire material, making it ideal for labels or stickers that need to be fully separated. Kiss cutting only cuts through the top layer without piercing the backing, allowing you to peel off the sticker while the liner remains intact.

Table of Comparison

| Feature | Die Cutting | Kiss Cutting |

|---|---|---|

| Definition | Cuts through entire material. | Cuts top layer only, leaving the backing intact. |

| Material Type | Used on thick or rigid materials like cardboard, plastic. | Used primarily on adhesive materials like sticker sheets. |

| Cut Depth | Full cut through material thickness. | Partial cut; surface layer only. |

| Main Applications | Boxes, packaging, labels, complex shapes. | Stickers, decals, labels that need backing protection. |

| Precision | High precision in shapes and edges. | Allows easy peeling of cuts without damaging backing. |

| Production Speed | Slower due to full cutting. | Faster due to shallow cutting. |

| Cost | Higher tooling costs, suitable for bulk runs. | Lower tooling costs, ideal for custom or small batches. |

Introduction to Die Cutting and Kiss Cutting

Die cutting involves cutting through the entire material to create precise shapes or designs, commonly used for labels, stickers, and packaging. Kiss cutting, on the other hand, cuts only through the top layer of a material, leaving the backing intact, allowing easy peeling without damaging the base. Both techniques utilize specialized dies and presses, but die cutting is ideal for standalone shapes while kiss cutting is preferred for sticker sheets and multiple label applications.

Understanding Die Cutting: Process and Applications

Die cutting involves using a sharp steel blade to cut through materials like paper, cardboard, vinyl, and fabric, creating precise shapes for packaging, labels, and promotional items. Kiss cutting, a sub-technique, cuts only the top layer of material while leaving the backing intact, ideal for stickers and decals. Understanding these processes helps you choose the right method for your project's design complexity and material type.

What is Kiss Cutting? Techniques Simplified

Kiss cutting involves slicing through the top layer of material, like vinyl or sticker paper, while leaving the backing intact for easy peeling, making it ideal for stickers and labels. This technique uses precision blades that cut only partially through the substrate compared to die cutting, which cuts entirely through all layers. Understanding kiss cutting helps you achieve clean, professional finishes for adhesive products without damaging the backing material.

Key Differences Between Die Cutting and Kiss Cutting

Die cutting involves cutting through the entire material, creating separate shapes, ideal for fully detached labels or stickers. Kiss cutting only pierces the top layer of a material without cutting through the backing, allowing stickers to stay attached to their liner for easy peel-off. Understanding these key differences helps you choose the right technique for precise customization and efficient label handling.

Material Compatibility: Die Cutting vs Kiss Cutting

Die cutting is compatible with a wide range of materials including thick cardstock, corrugated cardboard, and heavy plastics, allowing for intricate shapes and deep cuts. Kiss cutting, on the other hand, works best with thinner materials like vinyl, labels, and stickers, as it only cuts the top layer without piercing through the backing. Understanding the material compatibility of your project ensures precise cuts and optimal results with either die cutting or kiss cutting techniques.

Precision and Accuracy in Both Cutting Methods

Die cutting offers high precision and accuracy by using a custom-made steel die that ensures consistent, clean cuts through materials like cardstock, vinyl, and leather. Kiss cutting provides precise cuts as well, but it only slices through the top layer of material, preserving the backing for easy peeling, ideal for stickers and labels. Both methods rely on exact die design and proper machine calibration to maintain accuracy in intricate shapes and detailed designs.

Cost Comparison: Die Cutting vs Kiss Cutting

Die cutting generally incurs higher costs due to the need for custom steel rule dies and longer setup times, making it more suitable for large volume production runs. Kiss cutting, by contrast, uses less expensive tools and requires less downtime between runs, resulting in lower overall expenses for small to medium batch sizes. Businesses aiming to balance precision and budget often choose kiss cutting for intricate designs with reduced material waste.

Common Uses in Industry for Die and Kiss Cutting

Die cutting is widely used in industries requiring precise, full cuts such as packaging, labels, and custom-shaped materials for automotive or electronics components. Kiss cutting is common in sticker production, allowing the backing material to remain intact while the adhesive layer is cut, which is ideal for removable labels, decals, and tapes. Your choice between die cutting and kiss cutting depends on whether you need complete separation of the material or preservation of the backing for easy peeling and application.

Choosing the Right Cutting Method for Your Project

Choosing the right cutting method--die cutting or kiss cutting--depends on the project's material thickness, design complexity, and intended use. Die cutting provides clean, precise cuts through materials like cardstock and vinyl, ideal for stickers requiring full separation, while kiss cutting cuts through the top layer only, preserving the backing for easy peel-off applications. Analyzing production volume, budget, and adhesive type further ensures optimal results and durability for labels or custom shapes.

Conclusion: Which Cutting Method Should You Choose?

Choosing between die cutting and kiss cutting depends on the specific requirements of your project, such as material thickness and design complexity. Die cutting offers precise, clean cuts for thicker or more rigid materials, while kiss cutting is ideal for adhesive-backed products where the backing remains intact. Your decision should align with the final product's functionality, budget, and production speed to ensure optimal results.

Die cutting vs kiss cutting Infographic

libmatt.com

libmatt.com