Inline folding occurs directly within the current workflow or interface, allowing You to fold data or code in real-time without interrupting your tasks. Offline folding processes the information separately, often in the background or after initial input, improving efficiency by handling large amounts of data without immediate user interaction.

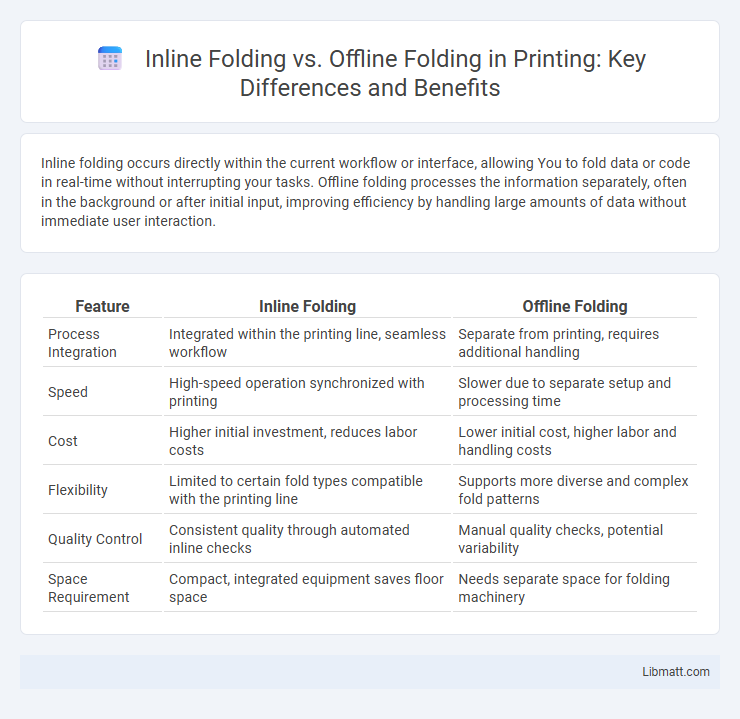

Table of Comparison

| Feature | Inline Folding | Offline Folding |

|---|---|---|

| Process Integration | Integrated within the printing line, seamless workflow | Separate from printing, requires additional handling |

| Speed | High-speed operation synchronized with printing | Slower due to separate setup and processing time |

| Cost | Higher initial investment, reduces labor costs | Lower initial cost, higher labor and handling costs |

| Flexibility | Limited to certain fold types compatible with the printing line | Supports more diverse and complex fold patterns |

| Quality Control | Consistent quality through automated inline checks | Manual quality checks, potential variability |

| Space Requirement | Compact, integrated equipment saves floor space | Needs separate space for folding machinery |

Introduction to Folding Techniques

Inline folding integrates the folding process directly within the production line, enhancing efficiency by minimizing handling and reducing cycle time. Offline folding operates separately from the main production, allowing for specialized attention to folding quality but potentially increasing overall processing time. Your choice between inline and offline folding depends on priorities such as speed, precision, and workflow integration in manufacturing or packaging applications.

What is Inline Folding?

Inline folding is a process where proteins or polymers fold into their functional three-dimensional structure during synthesis, typically occurring simultaneously with chain elongation on the ribosome or within the cell. This co-translational folding helps reduce misfolding and aggregation by allowing segments to adopt native conformations as they are produced. Understanding inline folding can improve your strategies for designing efficient protein expression and enhancing functional yield in biotechnological applications.

What is Offline Folding?

Offline folding refers to the process of simplifying protein structures using computational methods performed prior to experimental analysis, allowing researchers to predict protein conformations without real-time data input. This technique relies on algorithms and simulations run on pre-existing datasets, enabling efficient exploration of protein folding pathways and energy landscapes. Offline folding contrasts with inline folding, which occurs concurrently with experimental procedures, making offline methods crucial for in-depth structural prediction and virtual screening.

Key Differences Between Inline and Offline Folding

Inline folding integrates the folding process directly within the printing workflow, enabling immediate manipulation of printed sheets, whereas offline folding operates as a separate, post-printing process often requiring additional handling. Inline folding enhances efficiency and reduces production time by streamlining tasks, while offline folding offers greater flexibility with specialized folding types and larger equipment. The choice between inline and offline folding impacts overall productivity, cost, and the complexity of print finishing operations.

Advantages of Inline Folding

Inline folding offers significant advantages such as higher efficiency and faster production speeds by integrating folding directly into the printing process. This method reduces material handling and minimizes human error, leading to improved accuracy and consistent output quality. It also enhances workflow optimization by consolidating multiple steps into a seamless operation, reducing overall operational costs.

Advantages of Offline Folding

Offline folding offers significant advantages including the ability to perform complex computations without continuous internet access, ensuring data privacy and security by processing information locally. It reduces dependency on cloud servers, minimizing latency and potential downtime issues commonly associated with online services. Offline folding also enables resource optimization by leveraging local hardware capabilities, which can lead to faster and more efficient task completion compared to inline folding methods.

Limitations of Inline Folding

Inline folding is limited by its dependency on the immediate availability of folding patterns during the simulation process, which can lead to slower performance and reduced scalability for large protein sequences. This method often struggles with accurately predicting complex tertiary structures due to restricted computational resources and real-time data constraints. Offline folding bypasses these limitations by utilizing extensive pre-calculated data, enabling more precise and efficient modeling of protein folding pathways.

Limitations of Offline Folding

Offline folding restricts your ability to view real-time code changes, causing delays in debugging and development. It lacks the dynamic interaction that inline folding offers, limiting visibility into nested structures and making code navigation cumbersome. These limitations reduce productivity and complicate the understanding of complex code segments.

Choosing the Right Folding Method

Choosing the right folding method depends on your production needs, budget, and desired product finish. Inline folding integrates directly into the printing process, enabling faster turnaround and reduced labor costs, ideal for high-volume runs requiring consistent quality. Offline folding offers greater flexibility for diverse folding styles and smaller batches but may increase handling time and operational costs.

Future Trends in Folding Technology

Future trends in folding technology emphasize increased automation and integration of inline folding systems within production lines to enhance speed and precision. Offline folding machines continue to evolve with advanced robotics and AI-driven quality control for specialized, small-batch applications. Emerging innovations include smart sensors and IoT connectivity, enabling real-time monitoring and adaptive adjustments to optimize both inline and offline folding processes.

Inline folding vs offline folding Infographic

libmatt.com

libmatt.com