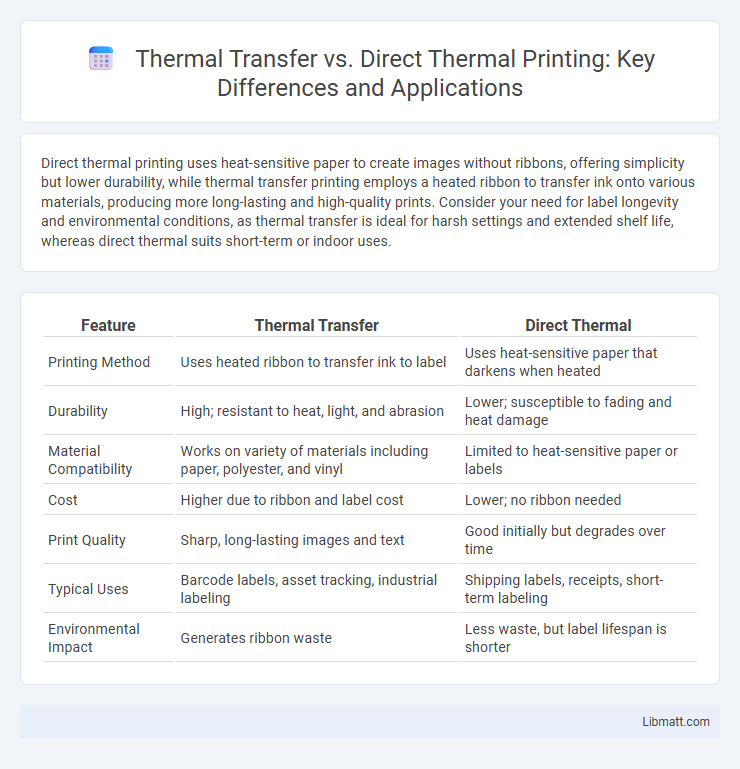

Direct thermal printing uses heat-sensitive paper to create images without ribbons, offering simplicity but lower durability, while thermal transfer printing employs a heated ribbon to transfer ink onto various materials, producing more long-lasting and high-quality prints. Consider your need for label longevity and environmental conditions, as thermal transfer is ideal for harsh settings and extended shelf life, whereas direct thermal suits short-term or indoor uses.

Table of Comparison

| Feature | Thermal Transfer | Direct Thermal |

|---|---|---|

| Printing Method | Uses heated ribbon to transfer ink to label | Uses heat-sensitive paper that darkens when heated |

| Durability | High; resistant to heat, light, and abrasion | Lower; susceptible to fading and heat damage |

| Material Compatibility | Works on variety of materials including paper, polyester, and vinyl | Limited to heat-sensitive paper or labels |

| Cost | Higher due to ribbon and label cost | Lower; no ribbon needed |

| Print Quality | Sharp, long-lasting images and text | Good initially but degrades over time |

| Typical Uses | Barcode labels, asset tracking, industrial labeling | Shipping labels, receipts, short-term labeling |

| Environmental Impact | Generates ribbon waste | Less waste, but label lifespan is shorter |

Introduction to Thermal Transfer and Direct Thermal Printing

Thermal transfer printing uses heat to melt ink from a ribbon onto a label, producing durable and long-lasting prints ideal for barcode labels and product identification. Direct thermal printing relies on heat-sensitive paper that blackens when heated, offering a cost-effective solution for short-term applications like shipping labels and receipts. Your choice between these methods depends on the required print longevity and environmental conditions.

How Thermal Transfer Printing Works

Thermal transfer printing uses a heated ribbon to transfer ink onto labels or tags, producing durable, high-quality images ideal for long-lasting applications. The heat melts the ink from the ribbon onto the substrate, resulting in sharp and smudge-resistant prints suitable for harsh environments. Your choice between thermal transfer and direct thermal depends on the label's intended lifespan and exposure conditions.

How Direct Thermal Printing Works

Direct thermal printing uses heat-sensitive paper that darkens when exposed to the printhead's heat, eliminating the need for ink, toner, or ribbons. The printhead selectively heats specific areas of the thermal paper to create images or text, making it ideal for short-term labeling like receipts or shipping labels. You get a simple, low-maintenance printing solution, but the prints may fade over time when exposed to heat or light.

Key Differences Between Thermal Transfer and Direct Thermal

Thermal transfer printing uses a ribbon to transfer ink onto labels, providing durable, long-lasting prints ideal for outdoor and industrial applications, while direct thermal printing heats specially coated paper, offering cost-effective, simplified printing but with shorter label lifespan. Direct thermal is preferred for short-term uses like shipping labels, whereas thermal transfer supports high-quality, fade-resistant barcodes essential for asset tracking and product identification. Your choice depends on print durability requirements and environmental exposure.

Advantages of Thermal Transfer Printing

Thermal transfer printing offers superior durability and resistance to heat, chemicals, and abrasion compared to direct thermal printing, making it ideal for long-lasting labels. It supports a broader range of materials such as synthetic films and textiles, enhancing versatility in industrial and commercial applications. This method delivers higher print quality and sharper barcode readability, ensuring reliable scanning and data accuracy.

Advantages of Direct Thermal Printing

Direct thermal printing offers distinct advantages such as eliminating the need for ink, toner, or ribbons, which reduces overall consumable costs and maintenance complexity. Its simplicity allows for faster, quieter operation ideal for high-speed or on-demand label printing in logistics, retail, and healthcare. You benefit from sharp, clear labels suitable for short-term use, making it perfect for shipping labels, receipts, and asset tags.

Limitations of Thermal Transfer Printing

Thermal transfer printing faces limitations such as the requirement for consumable ribbons, which increase operational costs and create waste. Print durability may decline on flexible or heat-sensitive materials, limiting substrate options compared to direct thermal printing. Additionally, thermal transfer printers tend to have slower print speeds and higher maintenance needs due to ribbon handling components.

Limitations of Direct Thermal Printing

Direct thermal printing faces limitations including sensitivity to heat and light, causing labels to fade or darken over time. It is unsuitable for long-term applications where durability and resistance to abrasion, chemicals, or outdoor exposure are required. Shelf life of direct thermal prints generally lasts only a few months, making thermal transfer printing preferable for extended label longevity.

Ideal Applications for Each Printing Method

Thermal transfer printing excels in creating durable, long-lasting labels suitable for outdoor use, asset tagging, and product identification due to its resistance to heat, chemicals, and abrasion. Direct thermal printing is ideal for short-term applications like shipping labels, receipts, and event tickets, where high-quality, cost-effective prints are needed without the use of ribbons. Each method optimizes print longevity and quality based on the specific environmental conditions and label lifespan requirements.

Choosing the Right Technology for Your Labeling Needs

Thermal transfer printing uses a ribbon to transfer ink onto labels, providing durability and resistance to heat, moisture, and chemicals, making it ideal for long-lasting labels in harsh environments. Direct thermal printing eliminates the need for ribbons by using heat-sensitive paper, offering a cost-effective solution for short-term labeling, such as shipping or retail tags. Choosing the right technology depends on your label longevity requirements, exposure conditions, and budget, ensuring optimal performance for your specific application.

Thermal transfer vs direct thermal Infographic

libmatt.com

libmatt.com