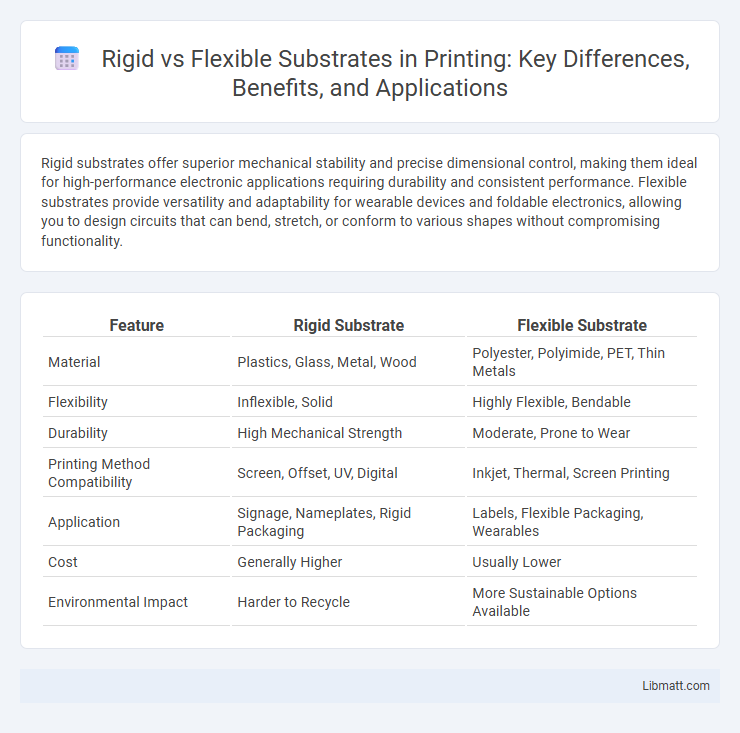

Rigid substrates offer superior mechanical stability and precise dimensional control, making them ideal for high-performance electronic applications requiring durability and consistent performance. Flexible substrates provide versatility and adaptability for wearable devices and foldable electronics, allowing you to design circuits that can bend, stretch, or conform to various shapes without compromising functionality.

Table of Comparison

| Feature | Rigid Substrate | Flexible Substrate |

|---|---|---|

| Material | Plastics, Glass, Metal, Wood | Polyester, Polyimide, PET, Thin Metals |

| Flexibility | Inflexible, Solid | Highly Flexible, Bendable |

| Durability | High Mechanical Strength | Moderate, Prone to Wear |

| Printing Method Compatibility | Screen, Offset, UV, Digital | Inkjet, Thermal, Screen Printing |

| Application | Signage, Nameplates, Rigid Packaging | Labels, Flexible Packaging, Wearables |

| Cost | Generally Higher | Usually Lower |

| Environmental Impact | Harder to Recycle | More Sustainable Options Available |

Introduction to Rigid and Flexible Substrates

Rigid substrates, commonly used in traditional electronics, provide a stable and durable platform ideal for high-performance applications requiring structural integrity, such as printed circuit boards (PCBs) made from materials like FR4 or ceramic. Flexible substrates, crafted from materials like polyimide or PET, enable lightweight, bendable designs that conform to various shapes, making them suitable for wearable technology and flexible displays. Your choice between rigid and flexible substrates depends on the specific mechanical and functional requirements of your electronic device.

Key Differences Between Rigid and Flexible Substrates

Rigid substrates, typically made of materials like FR4 or ceramic, provide a stable, durable base ideal for high-density electronic circuits due to their excellent mechanical strength and thermal resistance. Flexible substrates, often composed of polyimide or polyester films, offer enhanced pliability, allowing them to bend, fold, or conform to irregular surfaces, which is crucial for wearable devices and compact electronics. Your choice between these substrates depends on the application's mechanical requirements, thermal management needs, and space constraints.

Material Composition of Rigid Substrates

Rigid substrates, commonly composed of materials like FR4 (fiberglass epoxy resin), ceramics, and metals, provide a stable and durable base for electronic circuits due to their high mechanical strength and thermal resistance. These substrates offer excellent dimensional stability, ensuring precise component placement and long-term performance in harsh environments. Your choice of rigid substrate material directly impacts the circuit board's reliability, electrical insulation, and heat dissipation capabilities.

Material Composition of Flexible Substrates

Flexible substrates are typically composed of polymer-based materials such as polyimide (PI), polyethylene terephthalate (PET), and polyethylene naphthalate (PEN), which provide high mechanical flexibility and thermal stability. These materials offer excellent dielectric properties and resistance to moisture, making them ideal for applications in flexible electronics and wearable devices. The choice of polymer composition significantly influences the substrate's flexibility, durability, and compatibility with various fabrication processes compared to rigid substrates like glass or silicon.

Manufacturing Processes for Rigid vs Flexible Substrates

Manufacturing processes for rigid substrates typically involve high-temperature lamination, etching, and drilling on materials like FR-4 fiberglass, ensuring precise mechanical stability and electrical performance. Flexible substrates use lower-temperature processes such as roll-to-roll printing and laser cutting on polyimide or PET films to maintain flexibility while integrating conductive traces. Each method demands tailored equipment and process controls optimized for substrate thickness, thermal tolerance, and final application requirements like wearable electronics or automotive sensors.

Performance Characteristics and Durability

Rigid substrates offer superior structural integrity and consistent electrical performance, making them ideal for high-frequency applications requiring minimal signal loss. Flexible substrates provide enhanced durability through bendability and impact resistance, serving well in wearable electronics and dynamic environments. Your choice depends on balancing performance needs with mechanical flexibility for long-term reliability.

Common Applications in Electronics and Industry

Rigid substrates, commonly made from materials like FR4 or ceramic, are widely used in printed circuit boards (PCBs) for consumer electronics, automotive control systems, and industrial machinery due to their durability and thermal stability. Flexible substrates, often composed of polyimide or polyester films, enable the production of bendable and foldable devices found in wearable electronics, flexible displays, and medical sensors. Both substrate types are integral to advancing electronics manufacturing by balancing rigidity for structural support and flexibility for design innovation in various industrial applications.

Cost Comparison: Rigid vs Flexible Substrates

Rigid substrates generally have lower production costs due to established manufacturing processes and stable material availability, making them more economical for high-volume applications. Flexible substrates, while typically more expensive due to specialized materials like polyimide and complex fabrication techniques, offer advantages in lightweight and versatile design applications. Cost differences widen with scale, as rigid substrates benefit from economies of scale, whereas flexible substrates incur higher initial costs but add value in space-constrained and dynamic environments.

Advantages and Limitations of Each Substrate

Rigid substrates offer high mechanical stability and excellent dimensional accuracy, making them ideal for applications requiring precise component placement and durability, such as in aerospace and automotive electronics. However, their inflexibility and higher weight limit their use in wearable devices and foldable electronics. Flexible substrates provide lightweight, bendable properties essential for flexible displays and wearable sensors but face challenges in thermal management, mechanical robustness, and complex manufacturing processes.

Future Trends in Substrate Technology

Future trends in substrate technology emphasize the rise of flexible substrates, driven by the demand for lightweight, bendable, and wearable electronics. Innovations in materials such as polyimide, PET, and ultra-thin glass enable improved durability and performance in flexible substrates compared to traditional rigid substrates made from FR4 or ceramic. Your product designs will benefit from these advancements, offering enhanced customization and integration for next-generation electronic devices.

Rigid Substrate vs Flexible Substrate Infographic

libmatt.com

libmatt.com