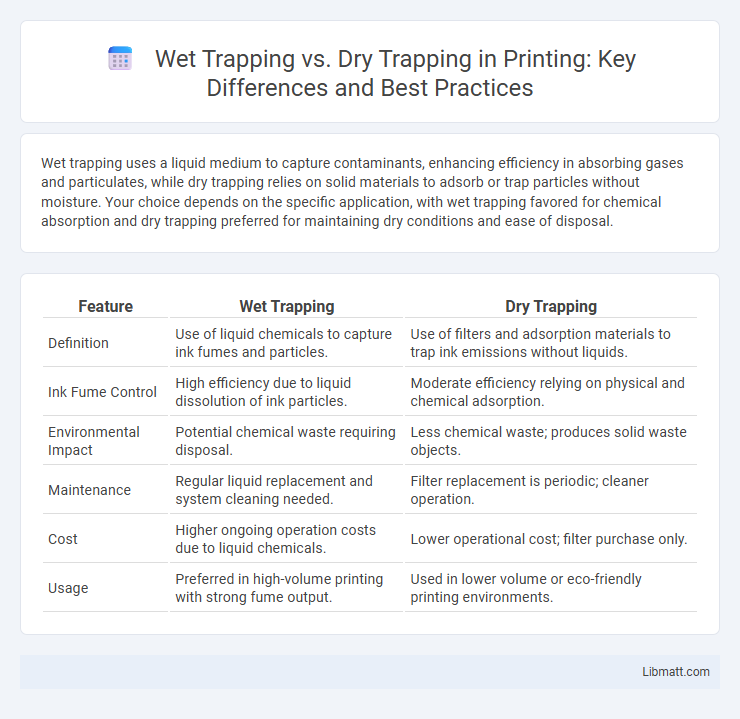

Wet trapping uses a liquid medium to capture contaminants, enhancing efficiency in absorbing gases and particulates, while dry trapping relies on solid materials to adsorb or trap particles without moisture. Your choice depends on the specific application, with wet trapping favored for chemical absorption and dry trapping preferred for maintaining dry conditions and ease of disposal.

Table of Comparison

| Feature | Wet Trapping | Dry Trapping |

|---|---|---|

| Definition | Use of liquid chemicals to capture ink fumes and particles. | Use of filters and adsorption materials to trap ink emissions without liquids. |

| Ink Fume Control | High efficiency due to liquid dissolution of ink particles. | Moderate efficiency relying on physical and chemical adsorption. |

| Environmental Impact | Potential chemical waste requiring disposal. | Less chemical waste; produces solid waste objects. |

| Maintenance | Regular liquid replacement and system cleaning needed. | Filter replacement is periodic; cleaner operation. |

| Cost | Higher ongoing operation costs due to liquid chemicals. | Lower operational cost; filter purchase only. |

| Usage | Preferred in high-volume printing with strong fume output. | Used in lower volume or eco-friendly printing environments. |

Introduction to Wet Trapping and Dry Trapping

Wet trapping uses a liquid medium to capture particles or contaminants, effectively trapping aerosols, dust, and chemical vapors in applications like industrial emissions control and laboratory fume hoods. Dry trapping relies on solid materials such as filters, adsorbents, or membranes to capture particles or gases without the use of liquids, making it ideal for air purification and filtration systems. Your choice between wet and dry trapping depends on factors like the type of contaminant, operational environment, and maintenance requirements.

Understanding the Fundamentals of Trapping Techniques

Wet trapping involves using liquid bait or moisture to attract and capture pests, enhancing effectiveness in environments where humidity or liquid presence is beneficial. Dry trapping relies on adhesive surfaces or mechanical devices without moisture, making it suitable for areas sensitive to wet conditions or contamination. Understanding these fundamental differences helps you select the appropriate trapping technique tailored to specific pest control needs and environmental factors.

Key Differences Between Wet Trapping and Dry Trapping

Wet trapping involves the use of liquid media to capture contaminants or particles, allowing for efficient removal of gases, vapors, or aerosols from industrial emissions. Dry trapping relies on solid materials, such as adsorbents or filters, to physically capture and retain pollutants without moisture, often preferred for collecting dry particulates or volatile organic compounds. Your choice between wet and dry trapping depends on factors like type of contaminants, operational environment, and specific capture efficiency required for emissions control.

Advantages of Wet Trapping Methods

Wet trapping methods offer superior efficiency in capturing airborne particles and gases by using a liquid medium to absorb contaminants directly from the air. This results in higher removal rates of fine particulates, toxic gases, and volatile organic compounds compared to dry trapping, improving air quality and operational safety. Your industrial or environmental applications benefit from reduced emissions and lower maintenance due to less clogging and easier waste disposal.

Benefits of Dry Trapping Approaches

Dry trapping offers significant benefits such as reduced maintenance and lower risk of corrosion compared to wet trapping. It efficiently captures contaminants without the use of liquids, minimizing disposal challenges and environmental impact. You can rely on dry trapping for improved system longevity and simplified operation in industrial and laboratory applications.

Common Applications of Wet and Dry Trapping

Wet trapping is commonly used in industrial processes involving exhaust gas treatment, chemical manufacturing, and air pollution control due to its efficiency in capturing soluble gases and particulate matter. Dry trapping finds frequent applications in laboratory settings, vacuum systems, and semiconductor fabrication where the removal of condensable vapors and fine particles without moisture is critical. Both methods serve essential roles in environmental monitoring, with wet traps excelling in scrubbing acidic gases and dry traps preferred for collecting non-condensable pollutants.

Efficiency and Effectiveness Comparison

Wet trapping uses liquid to capture contaminants, making it highly effective for trapping volatile organic compounds (VOCs) and gases with high solubility in liquids, leading to superior removal efficiency in humid environments. Dry trapping relies on solid adsorbents like activated carbon or silica gel, offering greater effectiveness in capturing particulates and non-polar compounds, but may have lower efficiency for water-soluble contaminants. Your choice between wet and dry trapping should consider the specific pollutants, environmental conditions, and desired removal efficiency to optimize overall treatment effectiveness.

Environmental and Safety Considerations

Wet trapping uses liquid solvents to capture contaminants, which can lead to hazardous waste disposal challenges and potential chemical spills, impacting environmental safety. Dry trapping avoids liquid chemicals, reducing risks of leaks and simplifying waste management but may generate dust or particulate matter requiring careful handling. Both methods necessitate proper ventilation and protective equipment to ensure worker safety and minimize environmental harm.

Factors to Consider When Choosing a Trapping Method

When choosing between wet trapping and dry trapping, factors such as the target species, environmental conditions, and ethical considerations play a critical role. Wet trapping is effective for aquatic or semi-aquatic animals and helps prevent escape, but requires proper water quality management to ensure animal welfare. Dry trapping allows for easier monitoring and handling of terrestrial animals, minimizing stress and injury risk, making it suitable for studies focusing on behavior or non-lethal sampling.

Conclusion: Selecting the Right Trapping Technique

Wet trapping offers efficient particle capture through liquid mediums, ideal for scenarios requiring high contamination control and easy sample extraction. Dry trapping excels in environments where moisture presence must be minimized, providing simpler maintenance and reduced corrosion risk. Choosing between wet and dry trapping depends on application-specific factors such as particle type, environmental conditions, and operation duration to optimize performance and cost-efficiency.

Wet trapping vs dry trapping Infographic

libmatt.com

libmatt.com