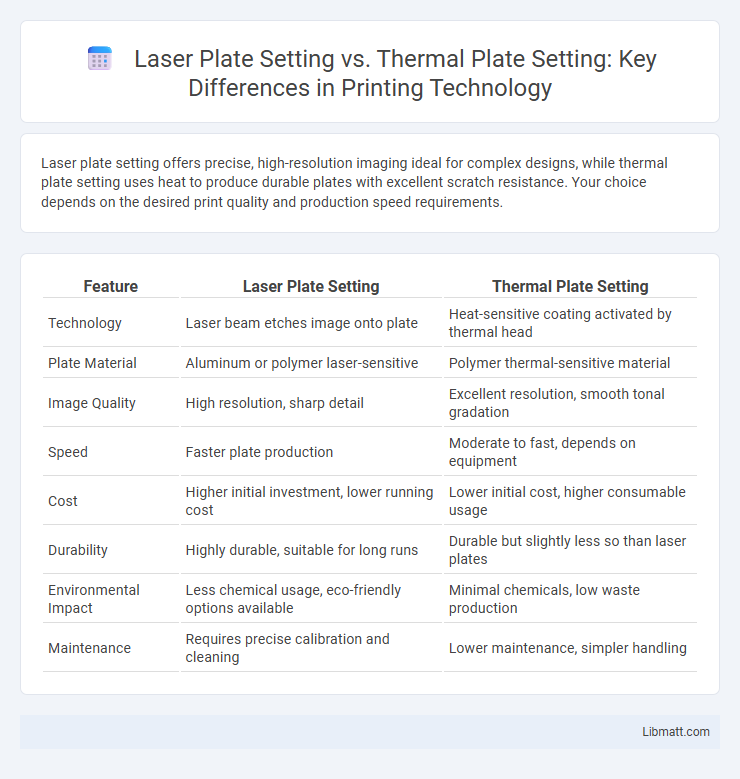

Laser plate setting offers precise, high-resolution imaging ideal for complex designs, while thermal plate setting uses heat to produce durable plates with excellent scratch resistance. Your choice depends on the desired print quality and production speed requirements.

Table of Comparison

| Feature | Laser Plate Setting | Thermal Plate Setting |

|---|---|---|

| Technology | Laser beam etches image onto plate | Heat-sensitive coating activated by thermal head |

| Plate Material | Aluminum or polymer laser-sensitive | Polymer thermal-sensitive material |

| Image Quality | High resolution, sharp detail | Excellent resolution, smooth tonal gradation |

| Speed | Faster plate production | Moderate to fast, depends on equipment |

| Cost | Higher initial investment, lower running cost | Lower initial cost, higher consumable usage |

| Durability | Highly durable, suitable for long runs | Durable but slightly less so than laser plates |

| Environmental Impact | Less chemical usage, eco-friendly options available | Minimal chemicals, low waste production |

| Maintenance | Requires precise calibration and cleaning | Lower maintenance, simpler handling |

Introduction to Plate Setting Technologies

Laser plate setting technology utilizes precise laser beams to image digital files directly onto printing plates, offering enhanced accuracy and faster processing times. Thermal plate setting employs heat-sensitive plates activated by infrared lasers, providing excellent durability and consistent image quality for high-volume printing operations. Your choice between these technologies depends on factors such as print run length, resolution requirements, and production speed, with laser systems often favored for their precision and thermal plates valued for robustness.

Overview of Laser Plate Setting

Laser plate setting employs digital technology to expose printing plates with high precision using laser beams, enhancing image quality and registration accuracy compared to traditional thermal plate setting. This method eliminates the need for chemical processing, reducing environmental impact and streamlining production workflows. Laser plate setting supports faster turnaround times and is compatible with various plate materials, making it ideal for high-volume, high-resolution printing applications.

Overview of Thermal Plate Setting

Thermal plate setting utilizes infrared lasers to create high-quality printing plates by exposing a photosensitive layer beneath an aluminum surface, resulting in precise, durable images for offset printing. This method offers faster processing times and improved consistency compared to traditional laser plate setting, enhancing productivity in commercial printing environments. Your choice of thermal plate setting can lead to more efficient workflows and higher fidelity in print production.

Key Differences Between Laser and Thermal Plate Setting

Laser plate setting uses a laser beam to directly image digital files onto the printing plate, offering high precision and faster processing times. Thermal plate setting employs heat-sensitive plates exposed to thermal printer heads, providing superior durability and resistance to environmental factors. The key differences include the imaging technology used, speed of plate production, and plate longevity in various printing environments.

Image Quality and Resolution Comparison

Laser plate setting delivers superior image quality and higher resolution compared to thermal plate setting due to its precise and stable laser technology, enabling finer detail reproduction and more consistent dot shapes. Thermal plate setting offers good quality but often shows slightly lower resolution and less sharpness because the heat-based imaging process can cause minor dot gain and variability. For applications demanding high fidelity and intricate image detail, laser plates provide a clear advantage in maintaining crisp, accurate printing output.

Speed and Productivity Analysis

Laser plate setting offers significantly faster turnaround times compared to thermal plate setting, enabling higher productivity in printing workflows. This technology reduces plate exposure and processing times, allowing your operations to handle larger volumes with quicker job completion. Thermal plate setting, while reliable, generally requires longer processing cycles, which can limit overall speed and throughput in high-demand environments.

Cost Efficiency: Laser vs Thermal

Laser plate setting offers higher cost efficiency through faster imaging speeds and reduced chemical usage, lowering overall production expenses. Thermal plate setting, while often providing superior durability and image quality, tends to involve higher initial equipment costs and increased energy consumption. Your choice depends on balancing upfront investment against long-term operational savings and print quality requirements.

Environmental Impact and Sustainability

Laser plate setting significantly reduces environmental impact by eliminating the need for chemical processing and decreasing water consumption compared to traditional thermal plate setting. It offers enhanced sustainability through lower energy usage and reduced generation of hazardous waste, contributing to eco-friendly printing operations. This shift supports compliance with stringent environmental regulations and promotes long-term ecological responsibility in the printing industry.

Best Applications for Each Technology

Laser plate setting excels in high-resolution printing demands such as fine art reproductions and detailed packaging labels, offering precise image quality and sharpness. Thermal plate setting suits large-scale commercial printing projects like newspapers and magazines, providing durability and fast processing speeds ideal for high-volume runs. Your choice depends on whether you prioritize intricate detail or rapid output efficiency.

Choosing the Right Plate Setting Method

Choosing the right plate setting method depends on the specific requirements of the printing job and the type of printing press used. Laser plate setting offers high precision and faster turnaround, making it ideal for short-run and high-resolution printing, while thermal plate setting provides superior durability and consistency for long-run commercial printing. Evaluating factors such as production volume, image quality demands, and budget constraints ensures optimal performance and cost-efficiency in plate making.

Laser plate setting vs thermal plate setting Infographic

libmatt.com

libmatt.com