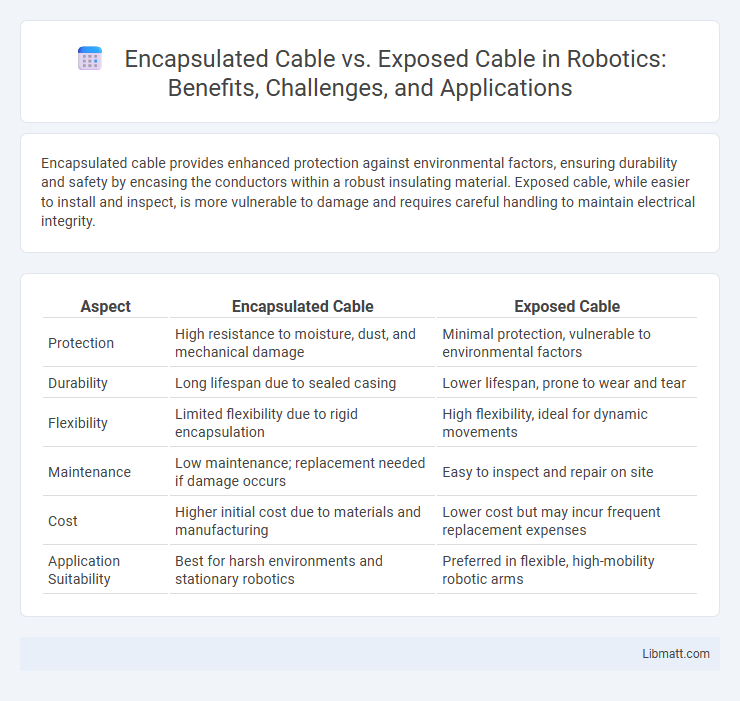

Encapsulated cable provides enhanced protection against environmental factors, ensuring durability and safety by encasing the conductors within a robust insulating material. Exposed cable, while easier to install and inspect, is more vulnerable to damage and requires careful handling to maintain electrical integrity.

Table of Comparison

| Aspect | Encapsulated Cable | Exposed Cable |

|---|---|---|

| Protection | High resistance to moisture, dust, and mechanical damage | Minimal protection, vulnerable to environmental factors |

| Durability | Long lifespan due to sealed casing | Lower lifespan, prone to wear and tear |

| Flexibility | Limited flexibility due to rigid encapsulation | High flexibility, ideal for dynamic movements |

| Maintenance | Low maintenance; replacement needed if damage occurs | Easy to inspect and repair on site |

| Cost | Higher initial cost due to materials and manufacturing | Lower cost but may incur frequent replacement expenses |

| Application Suitability | Best for harsh environments and stationary robotics | Preferred in flexible, high-mobility robotic arms |

Introduction to Cable Protection Methods

Encapsulated cables are enclosed within protective materials such as resin or plastic, providing enhanced resistance to moisture, chemicals, and mechanical damage, making them ideal for harsh environments. Exposed cables lack this outer protective layer, increasing vulnerability to environmental factors but allowing easier access for maintenance and modifications. Selecting between encapsulated and exposed cables depends on the application's durability requirements and maintenance considerations.

Definition of Encapsulated Cable

Encapsulated cable refers to electrical wiring that is completely covered by a protective insulating material, such as plastic or rubber, which shields the conductors from moisture, chemicals, and physical damage. This encapsulation enhances durability and safety, making it ideal for harsh environments where exposure to external elements is frequent. Your choice of encapsulated cable ensures long-lasting performance and reduced risk of electrical hazards.

Definition of Exposed Cable

Exposed cable refers to electrical wiring or cabling that is installed visibly on surfaces without protective coverings such as conduits or raceways, making the cables directly accessible and observable. This method is commonly used in environments where frequent maintenance or modifications are needed, or aesthetic considerations are secondary. However, exposed cables are more susceptible to physical damage, environmental factors, and safety hazards compared to encapsulated cable systems.

Key Differences Between Encapsulated and Exposed Cable

Encapsulated cables are protected by an outer insulating layer, offering superior resistance to environmental factors such as moisture, chemicals, and mechanical damage, whereas exposed cables lack this protective sheath and are more vulnerable to external hazards. Encapsulation enhances durability and safety in harsh industrial and outdoor settings, while exposed cables are typically used for indoor, controlled environments where ease of access and flexibility for maintenance are prioritized. The choice between encapsulated and exposed cables depends on application requirements including environmental exposure, safety standards, and installation complexity.

Advantages of Encapsulated Cable

Encapsulated cable offers superior protection against moisture, chemicals, and physical damage, ensuring longer lifespan and enhanced reliability in harsh environments. Its sealed design prevents corrosion and electrical faults, making it ideal for industrial and outdoor applications. By choosing encapsulated cable, you improve safety and reduce maintenance costs in your electrical installations.

Advantages of Exposed Cable

Exposed cables offer superior heat dissipation, reducing the risk of overheating and improving overall safety in electrical systems. They allow for easier inspection, maintenance, and fault detection, minimizing downtime and repair costs in industrial and commercial applications. The installation of exposed cables is often faster and more flexible, accommodating complex routing and modifications without the need for extensive enclosure adjustments.

Typical Applications for Each Cable Type

Encapsulated cables are commonly used in harsh environments such as underwater installations, industrial machinery, and outdoor electrical systems where protection from moisture, chemicals, and mechanical damage is critical. Exposed cables are typically found in indoor residential or commercial wiring, temporary setups, and areas where easy access and flexible routing are required. Selecting the appropriate cable type depends on factors like environmental exposure, durability needs, and installation complexity.

Safety Considerations and Compliance

Encapsulated cables provide superior safety by offering enhanced protection against moisture, chemicals, and mechanical damage, significantly reducing risks of electrical faults and fire hazards compared to exposed cables. Compliance with industry standards such as NEC (National Electrical Code) and IEC (International Electrotechnical Commission) often mandates encapsulated cables in hazardous or outdoor environments to ensure insulation integrity and operational safety. Exposed cables require stringent regular inspections and protective measures to meet safety regulations, whereas encapsulated cables generally facilitate easier compliance due to their robust protective encapsulation.

Cost Comparison and Installation Factors

Encapsulated cables typically incur higher upfront costs due to specialized materials and protective coatings designed to withstand harsh environments, whereas exposed cables offer a lower initial investment but may require more frequent maintenance and replacement. Installation of encapsulated cables demands careful handling and often longer labor time to ensure integrity and proper sealing, contrasting with exposed cables that allow faster, simpler installation but might need additional protective measures like conduits or trays. You should weigh the total cost of ownership, factoring in durability, environmental conditions, and long-term maintenance when deciding between encapsulated and exposed cable options.

Choosing the Right Cable Solution for Your Needs

Encapsulated cable offers enhanced protection against moisture, chemicals, and physical damage, making it ideal for harsh environments and industrial applications requiring long-term durability. Exposed cable provides easier access for inspection and maintenance, suitable for scenarios prioritizing flexibility and quick repairs. Selecting the right cable solution depends on environmental conditions, maintenance requirements, and budget considerations specific to your project.

Encapsulated Cable vs Exposed Cable Infographic

libmatt.com

libmatt.com