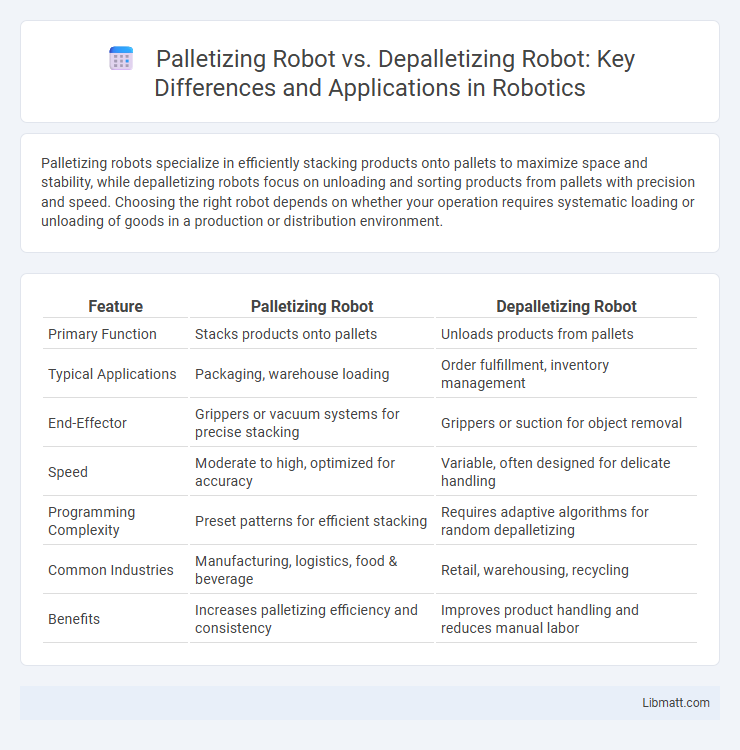

Palletizing robots specialize in efficiently stacking products onto pallets to maximize space and stability, while depalletizing robots focus on unloading and sorting products from pallets with precision and speed. Choosing the right robot depends on whether your operation requires systematic loading or unloading of goods in a production or distribution environment.

Table of Comparison

| Feature | Palletizing Robot | Depalletizing Robot |

|---|---|---|

| Primary Function | Stacks products onto pallets | Unloads products from pallets |

| Typical Applications | Packaging, warehouse loading | Order fulfillment, inventory management |

| End-Effector | Grippers or vacuum systems for precise stacking | Grippers or suction for object removal |

| Speed | Moderate to high, optimized for accuracy | Variable, often designed for delicate handling |

| Programming Complexity | Preset patterns for efficient stacking | Requires adaptive algorithms for random depalletizing |

| Common Industries | Manufacturing, logistics, food & beverage | Retail, warehousing, recycling |

| Benefits | Increases palletizing efficiency and consistency | Improves product handling and reduces manual labor |

Introduction to Palletizing and Depalletizing Robots

Palletizing robots automate the process of stacking products onto pallets, improving efficiency and precision in packaging and shipping operations. Depalletizing robots specialize in the reverse task, removing items from pallets for sorting, inspection, or repackaging, enhancing flexibility in warehouse and manufacturing environments. Understanding the roles of palletizing and depalletizing robots helps optimize your material handling system for faster turnaround and reduced labor costs.

Key Functions: Palletizing vs Depalletizing

Palletizing robots specialize in arranging products or packages onto pallets in a precise and efficient manner, optimizing storage and transportation. Depalletizing robots focus on unloading items from pallets, ensuring smooth unpacking and preparing goods for subsequent processing or distribution. Your choice depends on whether you need automated stacking or unstacking to streamline your warehouse operations.

Core Technologies Behind Both Robots

Palletizing robots utilize advanced vision systems and precise robotic arms to efficiently stack products onto pallets, optimizing space and ensuring stability. Depalletizing robots rely on machine learning algorithms and adaptive grippers to identify, decouple, and sort varied items from pallets with minimal human intervention. Both robots integrate real-time sensing and automation software to enhance speed, accuracy, and flexibility in warehouse logistics.

Benefits of Palletizing Robots

Palletizing robots offer significant benefits including increased speed, accuracy, and consistency in stacking products, which enhances overall warehouse productivity. These robots reduce labor costs and minimize workplace injuries by automating heavy lifting tasks, ensuring your operations run smoothly and safely. Investing in palletizing robots optimizes space utilization and supports seamless integration with existing logistics systems for improved supply chain efficiency.

Advantages of Depalletizing Robots

Depalletizing robots offer significant advantages in automating the unloading of products from pallets, reducing labor costs and minimizing human error in repetitive tasks. These robots enhance operational efficiency by handling various product sizes and shapes with precision, improving throughput in warehouses and distribution centers. Their flexibility in adapting to different pallet configurations and robust safety features also contribute to safer and more consistent depalletizing processes.

Typical Applications in Various Industries

Palletizing robots are commonly utilized in industries such as food and beverage, pharmaceuticals, and manufacturing for stacking products like cartons, bags, and boxes onto pallets efficiently. Depalletizing robots are essential in logistics, warehousing, and retail sectors for unloading and sorting goods from pallets, streamlining inbound goods handling. Both technologies enhance automation in supply chains by improving speed, accuracy, and reducing labor costs across diverse industrial applications.

Flexibility and Customization Capabilities

Palletizing robots offer high flexibility and customization capabilities, allowing adjustments in stacking patterns, load sizes, and pallet types to accommodate diverse production needs. Depalletizing robots excel in handling various container formats and package shapes, equipped with adaptable grippers and vision systems to efficiently reverse the palletizing process. Both robot types can be tailored with programmable software and modular end-effectors to optimize performance for specific operational requirements.

Speed, Accuracy, and Efficiency Comparison

Palletizing robots excel in speed, often handling up to 1500 cycles per hour with precise placement to maximize stack stability, while depalletizing robots prioritize accuracy to safely disassemble complex load patterns at around 900 cycles per hour. Efficiency in palletizing robots is driven by their ability to optimize space utilization and minimize downtime through consistent, repeatable motions. Your choice depends on whether you need rapid, systematic stacking or precise, adaptive unloading to enhance overall operational flow.

Integration with Warehouse Automation Systems

Palletizing robots efficiently automate the stacking of products onto pallets, streamlining the outbound logistics process by seamlessly integrating with warehouse automation systems like conveyor belts and inventory management software. Depalletizing robots specialize in unloading products from pallets, enhancing inbound sorting and quality control while syncing with automated storage and retrieval systems (ASRS) to optimize space utilization. Your warehouse benefits from improved operational flow and reduced labor costs when these robots are precisely integrated into your overall automation framework.

Future Trends in Robotic Material Handling

Palletizing robots are advancing with enhanced AI-driven precision and speed, enabling automated stacking of goods for efficient storage and shipping. Depalletizing robots are evolving to handle diverse, irregularly shaped items using sophisticated vision systems and adaptive grippers, optimizing your warehouse productivity. The future of robotic material handling integrates collaborative robots (cobots) that seamlessly work alongside humans, increasing flexibility and scalability in logistics operations.

Palletizing robot vs Depalletizing robot Infographic

libmatt.com

libmatt.com