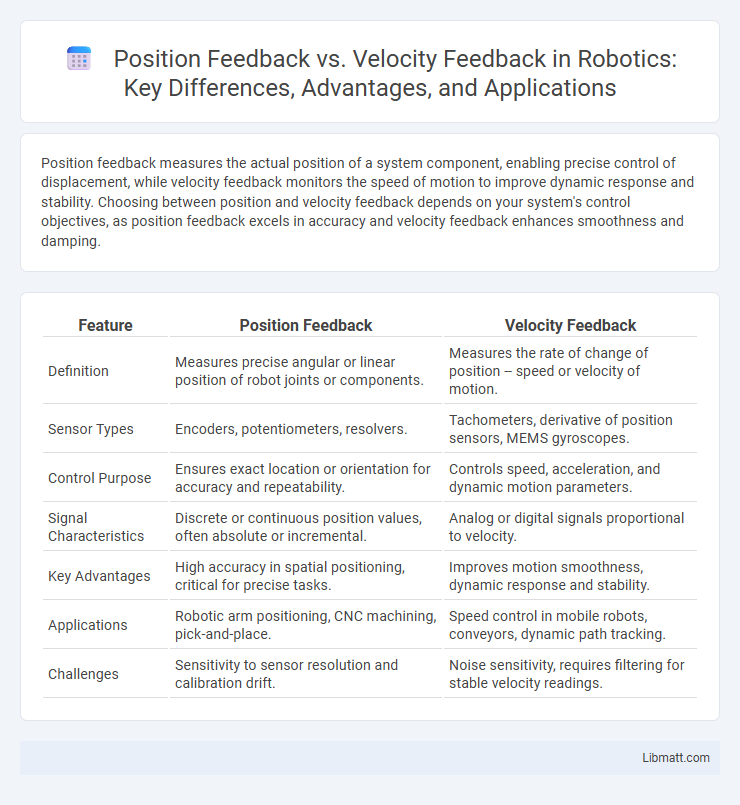

Position feedback measures the actual position of a system component, enabling precise control of displacement, while velocity feedback monitors the speed of motion to improve dynamic response and stability. Choosing between position and velocity feedback depends on your system's control objectives, as position feedback excels in accuracy and velocity feedback enhances smoothness and damping.

Table of Comparison

| Feature | Position Feedback | Velocity Feedback |

|---|---|---|

| Definition | Measures precise angular or linear position of robot joints or components. | Measures the rate of change of position -- speed or velocity of motion. |

| Sensor Types | Encoders, potentiometers, resolvers. | Tachometers, derivative of position sensors, MEMS gyroscopes. |

| Control Purpose | Ensures exact location or orientation for accuracy and repeatability. | Controls speed, acceleration, and dynamic motion parameters. |

| Signal Characteristics | Discrete or continuous position values, often absolute or incremental. | Analog or digital signals proportional to velocity. |

| Key Advantages | High accuracy in spatial positioning, critical for precise tasks. | Improves motion smoothness, dynamic response and stability. |

| Applications | Robotic arm positioning, CNC machining, pick-and-place. | Speed control in mobile robots, conveyors, dynamic path tracking. |

| Challenges | Sensitivity to sensor resolution and calibration drift. | Noise sensitivity, requires filtering for stable velocity readings. |

Introduction to Feedback Control Systems

Position feedback and velocity feedback are fundamental components in feedback control systems that regulate motion by continuously measuring and adjusting system variables. Position feedback provides real-time data on the exact location of a moving part, essential for precise control in robotics and CNC machines, while velocity feedback monitors the speed and direction, crucial for maintaining stability and smooth motion in motor drives. Your choice between position and velocity feedback impacts system responsiveness and accuracy, determining overall control performance based on application requirements.

Defining Position Feedback

Position feedback measures the exact location or displacement of a system component relative to a reference point, providing precise data essential for control accuracy. It enables systems to correct errors by continuously comparing the actual position against the desired position, ensuring minimal deviation in applications such as robotics and CNC machines. Position feedback relies on sensors like encoders or potentiometers to deliver real-time positional information critical for maintaining control stability and performance.

Understanding Velocity Feedback

Velocity feedback measures the rate of change of position over time, providing real-time information on how fast a system moves rather than its absolute position. This feedback type is essential in control systems for improving dynamic response, reducing overshoot, and enhancing system stability by adjusting control actions based on speed variations. Unlike position feedback, which tracks precise location, velocity feedback offers critical data for smooth acceleration and deceleration in applications such as robotics, motor control, and aerospace navigation.

Key Differences Between Position and Velocity Feedback

Position feedback measures the actual angular or linear displacement of a system, providing precise information on the exact location of a mechanical component. Velocity feedback captures the speed and direction of motion, essential for controlling dynamic responses and damping oscillations in control systems. Key differences include that position feedback offers a static reference point vital for accurate positioning, while velocity feedback enables real-time monitoring of motion to improve stability and responsiveness.

Advantages of Position Feedback

Position feedback provides precise control by continuously monitoring the exact location of a system component, enabling accurate and stable operation. It reduces steady-state error and improves the system's ability to maintain a desired position under varying loads. Your control system benefits from enhanced accuracy and reliability, making position feedback ideal for applications requiring precise movement and positioning.

Benefits of Velocity Feedback

Velocity feedback enhances system stability by reducing overshoot and oscillations, leading to smoother dynamic response in control systems. It improves disturbance rejection and enables faster error correction, which is crucial for applications requiring precise speed regulation and responsive control. In contrast to position feedback, velocity feedback provides real-time information on motion changes, facilitating better damping and increased robustness in feedback loops.

Application Examples: Position vs Velocity Feedback

Position feedback is essential in applications requiring precise control of an object's location, such as CNC machines, robotic arms, and elevator systems, where maintaining exact positioning is critical. Velocity feedback is commonly utilized in motor speed control, conveyor belts, and automotive cruise control systems to regulate and stabilize motion speed. Your choice between position and velocity feedback depends on whether accuracy in displacement or consistency in speed is the primary control objective.

Impact on System Stability and Performance

Position feedback provides accurate control of system output by minimizing steady-state errors, enhancing precision and stability in applications requiring exact positioning. Velocity feedback improves system damping and responsiveness, reducing overshoot and oscillations to boost dynamic performance and robustness. Combining both feedback types often results in optimal stability and performance by balancing precision and rapid response in your control system.

Choosing the Right Feedback Type for Your Application

Selecting between position feedback and velocity feedback depends on the control requirements of your system: position feedback offers precise control of the absolute or relative position, ideal for applications demanding accurate placement and trajectory tracking; velocity feedback provides real-time speed data crucial for dynamic control scenarios, such as maintaining consistent motor speed or damping oscillations. Systems requiring stability and smooth motion benefit from velocity feedback integrated with position feedback to enhance performance and responsiveness. Evaluating the application's need for accuracy, speed control, and system complexity ensures the optimal feedback type improves overall control and efficiency.

Summary and Best Practices

Position feedback provides precise information about the exact location of a system component, while velocity feedback measures the speed of movement, enabling smoother and more responsive control. Best practices recommend combining both feedback types to optimize system performance, with position feedback ensuring accuracy and velocity feedback enhancing dynamic response. Incorporate your system's specific requirements to balance the trade-offs between stability and responsiveness effectively.

Position feedback vs Velocity feedback Infographic

libmatt.com

libmatt.com