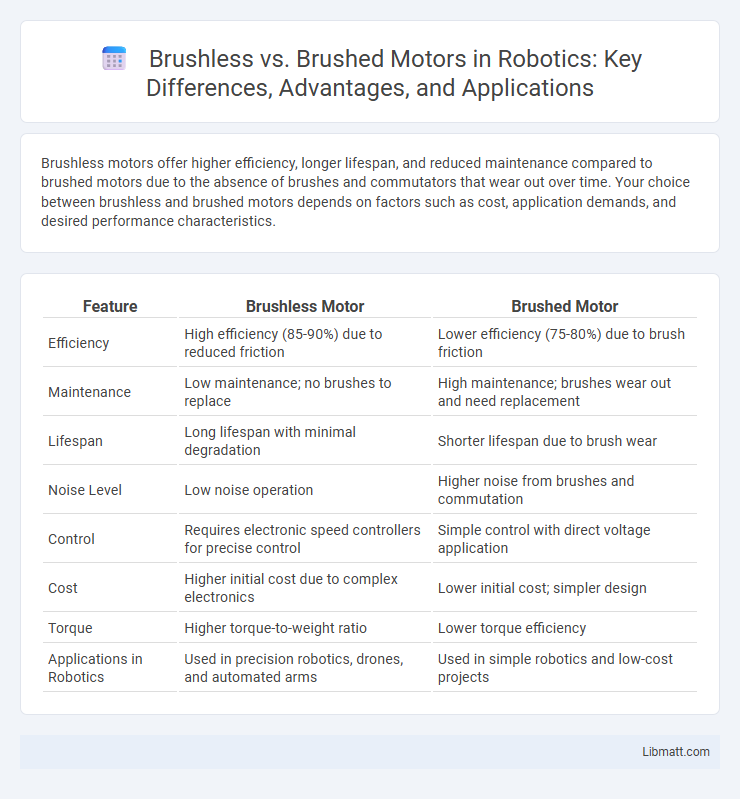

Brushless motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed motors due to the absence of brushes and commutators that wear out over time. Your choice between brushless and brushed motors depends on factors such as cost, application demands, and desired performance characteristics.

Table of Comparison

| Feature | Brushless Motor | Brushed Motor |

|---|---|---|

| Efficiency | High efficiency (85-90%) due to reduced friction | Lower efficiency (75-80%) due to brush friction |

| Maintenance | Low maintenance; no brushes to replace | High maintenance; brushes wear out and need replacement |

| Lifespan | Long lifespan with minimal degradation | Shorter lifespan due to brush wear |

| Noise Level | Low noise operation | Higher noise from brushes and commutation |

| Control | Requires electronic speed controllers for precise control | Simple control with direct voltage application |

| Cost | Higher initial cost due to complex electronics | Lower initial cost; simpler design |

| Torque | Higher torque-to-weight ratio | Lower torque efficiency |

| Applications in Robotics | Used in precision robotics, drones, and automated arms | Used in simple robotics and low-cost projects |

Introduction to Brushless and Brushed Motors

Brushless motors utilize electronic commutation and permanent magnets, offering higher efficiency and longer lifespan compared to brushed motors. Brushed motors rely on mechanical brushes and a commutator to deliver current to the rotor, resulting in more maintenance and wear over time. The absence of brushes in brushless motors reduces friction and electrical noise, making them ideal for precision and high-performance applications.

How Brushed Motors Work

Brushed motors operate by using carbon brushes that make physical contact with a rotating commutator to deliver current to the motor windings, creating a magnetic field that causes the rotor to spin. This contact switches the current direction, allowing continuous rotation and producing torque. While simple and cost-effective, the friction between brushes and commutator causes wear and limits efficiency compared to brushless motors.

How Brushless Motors Work

Brushless motors operate using electronic commutation instead of mechanical brushes, where a controller energizes stator coils in a specific sequence to create a rotating magnetic field. This rotating field interacts with permanent magnets attached to the rotor, causing it to spin without direct electrical contact. The absence of brushes reduces friction, increases efficiency, and extends the motor's lifespan compared to brushed motors.

Key Differences Between Brushless and Brushed Motors

Brushless motors use electronic commutation, eliminating brushes and reducing maintenance, whereas brushed motors rely on physical brushes for commutation, leading to wear and tear. Brushless motors offer higher efficiency, longer lifespan, and quieter operation compared to brushed motors, which are simpler and typically cost less. The absence of brushes in brushless motors enables better speed control and heat dissipation, making them ideal for high-performance applications.

Efficiency Comparison: Brushless vs Brushed

Brushless motors offer significantly higher efficiency than brushed motors due to the absence of frictional losses from brushes and commutators, leading to reduced energy consumption and longer operational lifespan. The electronic commutation system in brushless motors ensures precise control and minimal power loss, often achieving efficiency ratings above 85%, whereas brushed motors typically operate around 75%. This improved efficiency translates into better performance, lower heat generation, and increased reliability in applications ranging from electric vehicles to industrial machinery.

Durability and Maintenance Requirements

Brushless motors offer significantly higher durability compared to brushed motors due to the absence of brushes, which eliminates wear and tear associated with friction. Maintenance requirements for brushless motors are minimal, as they do not require periodic brush replacements or commutator cleaning, unlike brushed motors that need frequent upkeep to ensure optimal performance. The longer lifespan and reduced maintenance costs make brushless motors ideal for applications demanding reliability and continuous operation.

Performance and Power Output

Brushless motors deliver higher performance and power output compared to brushed motors due to their efficient electronic commutation and reduced friction. Your applications benefit from improved torque, longer lifespan, and better heat dissipation, enabling sustained high-speed operation. Brushless motors also provide more precise control, resulting in enhanced overall efficiency and reliability in demanding environments.

Cost Analysis: Initial and Long-term Expenses

Brushless motors have a higher initial cost due to complex design and electronic controllers, but they offer lower long-term expenses through increased efficiency, minimal maintenance, and longer lifespan. Brushed motors feature lower upfront prices but incur higher maintenance costs and frequent replacements of brushes and commutators. Over time, brushless motors provide better cost-effectiveness despite the steeper initial investment.

Applications: Where Each Motor Type Excels

Brushless motors excel in applications requiring high efficiency, reliability, and low maintenance, such as drones, electric vehicles, and computer cooling systems, due to their superior torque-to-weight ratio and longer lifespan. Brushed motors perform well in cost-sensitive, simple applications like household appliances, power tools, and toys, where initial affordability and straightforward control are crucial. The choice between brushless and brushed motors largely depends on the specific operational demands and budget constraints of the application.

Choosing the Right Motor for Your Needs

Brushless motors offer higher efficiency, longer lifespan, and lower maintenance compared to brushed motors, making them ideal for applications requiring precision and durability such as drones and electric vehicles. Brushed motors provide a cost-effective solution suitable for simpler, low-speed tasks like household appliances and power tools. Evaluating factors like torque requirements, operational environment, and budget helps determine whether the advanced performance of brushless motors or the affordability of brushed motors aligns better with specific project needs.

Brushless Motor vs Brushed Motor Infographic

libmatt.com

libmatt.com