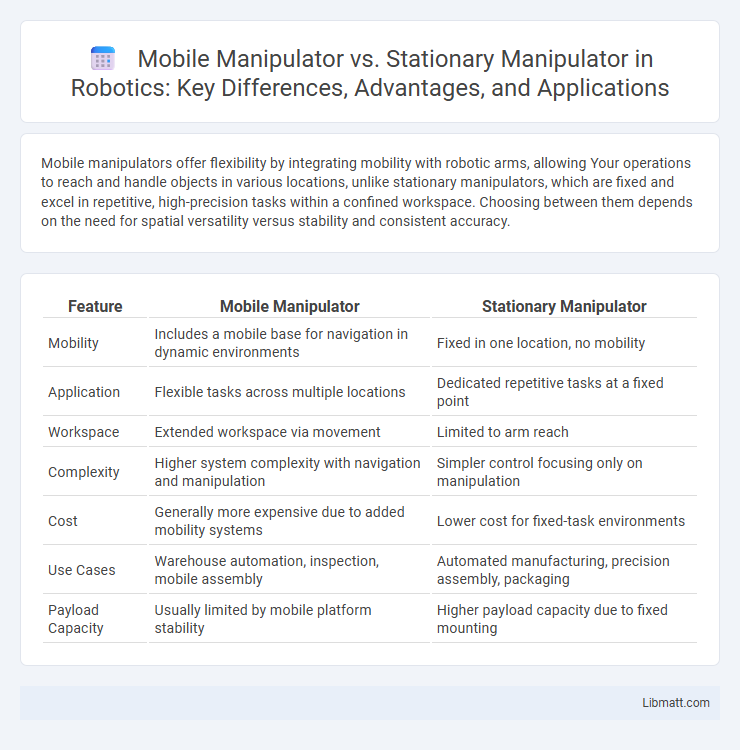

Mobile manipulators offer flexibility by integrating mobility with robotic arms, allowing Your operations to reach and handle objects in various locations, unlike stationary manipulators, which are fixed and excel in repetitive, high-precision tasks within a confined workspace. Choosing between them depends on the need for spatial versatility versus stability and consistent accuracy.

Table of Comparison

| Feature | Mobile Manipulator | Stationary Manipulator |

|---|---|---|

| Mobility | Includes a mobile base for navigation in dynamic environments | Fixed in one location, no mobility |

| Application | Flexible tasks across multiple locations | Dedicated repetitive tasks at a fixed point |

| Workspace | Extended workspace via movement | Limited to arm reach |

| Complexity | Higher system complexity with navigation and manipulation | Simpler control focusing only on manipulation |

| Cost | Generally more expensive due to added mobility systems | Lower cost for fixed-task environments |

| Use Cases | Warehouse automation, inspection, mobile assembly | Automated manufacturing, precision assembly, packaging |

| Payload Capacity | Usually limited by mobile platform stability | Higher payload capacity due to fixed mounting |

Introduction to Manipulators

Manipulators are robotic devices designed to perform tasks by mimicking human arm movements, with mobile manipulators featuring integrated mobility systems enabling them to navigate dynamic environments, while stationary manipulators are fixed in one location for precise, repetitive tasks. Mobile manipulators combine robotic arms with mobile platforms, facilitating flexible automation in sectors such as manufacturing, warehousing, and healthcare. Stationary manipulators, with fixed bases, specialize in high-precision operations like assembly, welding, and material handling in controlled industrial settings.

Defining Mobile Manipulators

Mobile manipulators combine robotic arms with mobility platforms, enabling them to navigate diverse environments while performing complex tasks. Unlike stationary manipulators fixed in one location, mobile manipulators enhance operational flexibility and expand application range across industries like logistics, healthcare, and manufacturing. Your choice between mobile and stationary manipulators depends on task requirements, workspace dynamics, and the need for adaptability.

Overview of Stationary Manipulators

Stationary manipulators are fixed robotic arms designed for high-precision tasks in manufacturing and assembly lines, offering stability and consistent repeatability. These manipulators excel in environments requiring heavy payload handling and intricate movements within a limited workspace. Choosing a stationary manipulator ensures enhanced accuracy and reliability, making it ideal for tasks where your operations demand consistent performance without mobility.

Key Differences Between Mobile and Stationary Manipulators

Mobile manipulators combine robotic arms with a mobile base, allowing them to perform tasks across diverse environments, enhancing flexibility and reach. Stationary manipulators are fixed in place, offering higher precision and stability for repetitive or heavy-duty tasks in controlled settings. Mobility enables greater operational range in mobile manipulators, while stationary manipulators prioritize strength and accuracy.

Mobility and Flexibility Comparison

Mobile manipulators offer enhanced mobility by integrating robotic arms with mobile platforms, enabling operations across multiple locations and dynamic environments. Stationary manipulators, fixed in one position, deliver high precision and stability but lack the ability to adapt quickly to varying tasks or locations. The combination of mobility and flexibility in mobile manipulators makes them ideal for industries requiring versatile automation solutions, while stationary manipulators excel in repetitive, high-accuracy tasks within a defined workspace.

Work Envelope and Reach Capabilities

Mobile manipulators offer an extended work envelope by combining robotic arms with mobile platforms, enabling reach across larger and more complex environments compared to stationary manipulators. Stationary manipulators are limited to a fixed position, restricting their operational workspace to a predefined radius, but they typically provide higher precision and payload capacity within that range. Your choice depends on the need for flexibility and reach versus stability and consistent reach capabilities in a confined workspace.

Applications in Industry

Mobile manipulators excel in dynamic industrial environments such as logistics, warehousing, and large-scale assembly lines where flexibility and reach are paramount. Stationary manipulators dominate precision tasks in automotive manufacturing, electronics assembly, and repetitive, high-speed operations requiring consistent accuracy. Your choice between them depends on the specific industrial application and the required balance between mobility and fixed, high-precision performance.

Integration and Automation Considerations

Mobile manipulators offer enhanced integration flexibility by combining robotic arms with mobility platforms, enabling seamless automation across dynamic environments and varied workspaces. Stationary manipulators provide stable and precise automation within fixed, controlled settings but may require complex reconfiguration for integration into changing production lines. When planning your automation strategy, consider mobile manipulators for versatile tasks and stationary units for high-precision, consistent operations.

Cost, Maintenance, and Scalability

Mobile manipulators generally incur higher initial costs due to their integrated mobility systems and advanced sensors, whereas stationary manipulators are typically more affordable and simpler in design. Maintenance for mobile manipulators tends to be more complex and frequent as they combine robotic arms with locomotion components, while stationary manipulators require less upkeep focused primarily on joint and actuator servicing. Scalability favors mobile manipulators, offering flexible deployment across different locations and tasks in your facility, while stationary manipulators excel in fixed, high-volume production environments with predictable workflows.

Choosing the Right Manipulator for Your Needs

Mobile manipulators offer enhanced flexibility and reach by combining robotic arms with mobility platforms, ideal for dynamic environments requiring versatile task execution. Stationary manipulators provide higher precision and payload capacity in fixed locations, making them suitable for repetitive tasks in controlled industrial settings. Selecting the right manipulator depends on factors such as workspace layout, task complexity, and production volume, ensuring optimal efficiency and cost-effectiveness.

Mobile manipulator vs Stationary manipulator Infographic

libmatt.com

libmatt.com