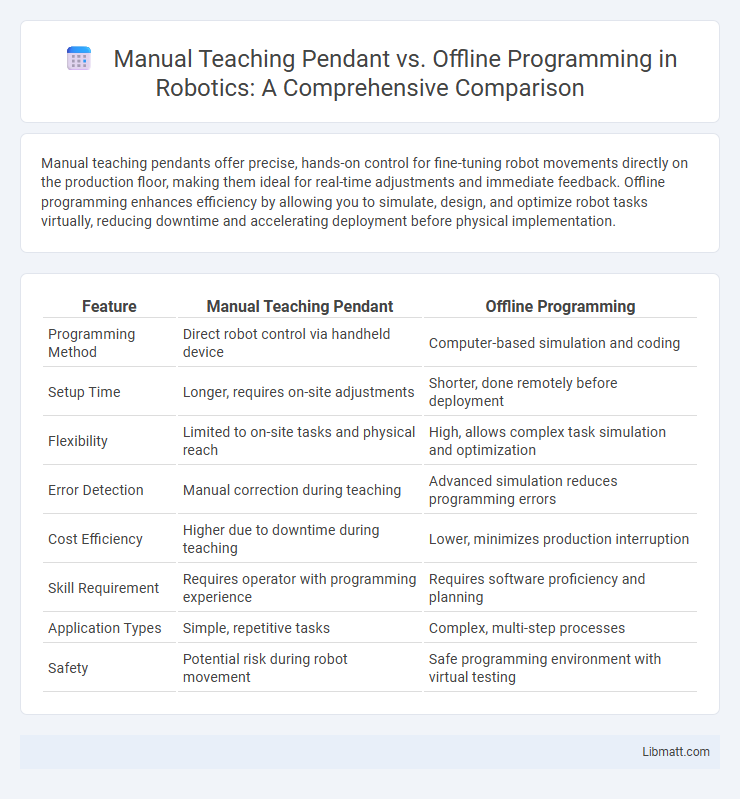

Manual teaching pendants offer precise, hands-on control for fine-tuning robot movements directly on the production floor, making them ideal for real-time adjustments and immediate feedback. Offline programming enhances efficiency by allowing you to simulate, design, and optimize robot tasks virtually, reducing downtime and accelerating deployment before physical implementation.

Table of Comparison

| Feature | Manual Teaching Pendant | Offline Programming |

|---|---|---|

| Programming Method | Direct robot control via handheld device | Computer-based simulation and coding |

| Setup Time | Longer, requires on-site adjustments | Shorter, done remotely before deployment |

| Flexibility | Limited to on-site tasks and physical reach | High, allows complex task simulation and optimization |

| Error Detection | Manual correction during teaching | Advanced simulation reduces programming errors |

| Cost Efficiency | Higher due to downtime during teaching | Lower, minimizes production interruption |

| Skill Requirement | Requires operator with programming experience | Requires software proficiency and planning |

| Application Types | Simple, repetitive tasks | Complex, multi-step processes |

| Safety | Potential risk during robot movement | Safe programming environment with virtual testing |

Introduction to Robot Programming Methods

Manual teaching pendant involves direct robot manipulation through a handheld device, allowing operators to record specific positions and actions in real-time. Offline programming utilizes computer software to create and simulate robot paths without stopping production, enhancing efficiency and reducing downtime. Both methods are essential in robot programming, balancing hands-on precision with pre-planned automation.

What is Manual Teaching Pendant Programming?

Manual teaching pendant programming involves the direct control of a robot through a handheld device, allowing an operator to teach precise movements by physically guiding the robot or inputting commands. This method provides real-time feedback and immediate adjustments, enhancing accuracy in complex or custom tasks. It contrasts with offline programming, which relies on pre-designed simulations without physical interaction.

Overview of Offline Robot Programming

Offline robot programming enables engineers to create and simulate robot tasks in a virtual environment without interrupting production, increasing efficiency and reducing downtime. Unlike manual teaching pendants requiring direct robot interaction for task setup, offline programming uses CAD models and simulation software to optimize robot paths and operations ahead of deployment. This approach supports complex programming, error reduction, and faster implementation of robotic automation in manufacturing processes.

Setup and Workflow Comparison

Manual teaching pendant setup requires physical interaction with the robot to record positions, making the process hands-on but time-consuming. Offline programming enables digital simulation and trajectory planning in specialized software, allowing for efficient iterations without stopping production. Workflow with manual teaching depends on real-time adjustments, while offline programming streamlines project development through virtual testing and integration.

Time Efficiency: Pendant vs Offline

Manual teaching pendants require operators to physically guide robots through tasks, which can be time-consuming and less efficient for complex or repetitive jobs. Offline programming enables users to create, simulate, and optimize robot paths in virtual environments before deployment, significantly reducing downtime and accelerating production schedules. Studies show offline programming can cut setup time by up to 50% compared to manual pendant teaching, enhancing overall time efficiency in robotic automation.

Accuracy and Error Reduction

Manual teaching pendants rely heavily on operator skill, leading to potential inaccuracies and a higher risk of human error during robot programming. Offline programming uses digital simulations and virtual models, significantly enhancing accuracy by allowing thorough testing and error correction before deployment. This approach reduces costly mistakes, improves precision, and streamlines the overall automation process.

Flexibility in Program Modifications

Manual teaching pendants offer real-time flexibility in program modifications by allowing direct, on-site adjustments to robot motion and parameters, ensuring immediate adaptation to changing tasks. Offline programming provides a robust environment for complex program revisions without halting production, enabling simulation and optimization before deployment. Your choice between these methods depends on the priority of instant adaptability versus thorough pre-planning and efficiency in making program changes.

Cost Implications of Each Method

Manual teaching pendants often incur higher labor costs due to the extended time required for operators to program robots directly on-site, increasing downtime and reducing overall productivity. Offline programming minimizes production loss by enabling robot programming on separate workstations, though it requires an initial investment in specialized software and IT infrastructure. The choice between methods ultimately hinges on balancing immediate upfront costs with long-term savings in efficiency and reduced operational disruptions.

Suitability for Different Applications

Manual teaching pendants excel in applications requiring precise, real-time adjustments and on-the-spot programming, making them ideal for small batch production or custom tasks. Offline programming is better suited for complex, high-volume manufacturing processes where simulation and error reduction before deployment are essential. Different applications benefit from these methods based on production scale, complexity, and need for flexibility.

Future Trends in Robot Programming

Future trends in robot programming emphasize the integration of offline programming tools that utilize advanced simulation and AI-driven optimization to reduce production downtime and enhance precision. Manual teaching pendants remain crucial for fine-tuning and adaptive tasks requiring human intuition and real-time adjustments on the factory floor. Hybrid approaches combining offline programming efficiency with manual pendant flexibility are expected to dominate, enabling seamless collaboration between humans and robots in dynamic manufacturing environments.

Manual teaching pendant vs Offline programming Infographic

libmatt.com

libmatt.com