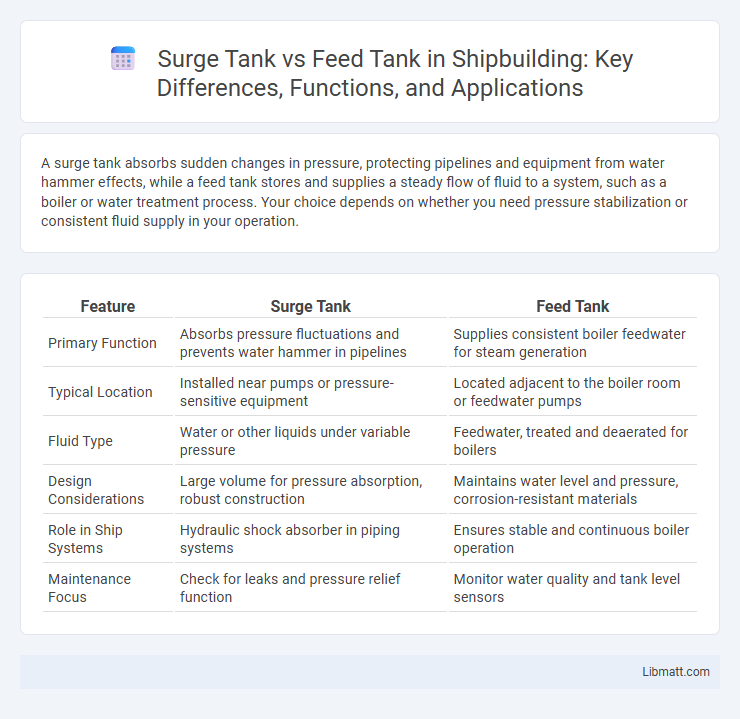

A surge tank absorbs sudden changes in pressure, protecting pipelines and equipment from water hammer effects, while a feed tank stores and supplies a steady flow of fluid to a system, such as a boiler or water treatment process. Your choice depends on whether you need pressure stabilization or consistent fluid supply in your operation.

Table of Comparison

| Feature | Surge Tank | Feed Tank |

|---|---|---|

| Primary Function | Absorbs pressure fluctuations and prevents water hammer in pipelines | Supplies consistent boiler feedwater for steam generation |

| Typical Location | Installed near pumps or pressure-sensitive equipment | Located adjacent to the boiler room or feedwater pumps |

| Fluid Type | Water or other liquids under variable pressure | Feedwater, treated and deaerated for boilers |

| Design Considerations | Large volume for pressure absorption, robust construction | Maintains water level and pressure, corrosion-resistant materials |

| Role in Ship Systems | Hydraulic shock absorber in piping systems | Ensures stable and continuous boiler operation |

| Maintenance Focus | Check for leaks and pressure relief function | Monitor water quality and tank level sensors |

Introduction to Surge Tanks and Feed Tanks

Surge tanks are designed to absorb sudden changes in water pressure within hydraulic systems, preventing water hammer and system shocks. Feed tanks serve as reservoirs that supply consistent water flow to boilers or processing equipment, maintaining proper fluid levels and pressure. Understanding the distinct roles of surge tanks and feed tanks helps optimize your system's hydraulic stability and operational efficiency.

Definition and Core Functions

A surge tank is a protective device designed to absorb sudden changes in water pressure within piping systems, preventing water hammer and pressure surges. A feed tank supplies a continuous, steady flow of water or feedwater to boilers or other processing units, maintaining system stability. Understanding the distinct roles of a surge tank and a feed tank helps you optimize fluid management and system safety in industrial applications.

Key Differences: Surge Tank vs Feed Tank

Surge tanks primarily manage pressure fluctuations and protect pipeline systems from water hammer by absorbing sudden changes in water flow, whereas feed tanks supply a steady volume of water to boilers or pumps ensuring continuous operation. The key difference lies in their function: surge tanks act as buffer storage for transient pressure control, while feed tanks provide a consistent water source for process stability. Understanding these distinctions helps you optimize system design for safety and efficiency in fluid handling applications.

Design and Structural Features

Surge tanks are designed to absorb sudden changes in pressure within pipelines and typically feature robust cylindrical or spherical structures with pressure-resistant walls to withstand shock loads. Feed tanks, in contrast, are engineered primarily for steady storage and supply of liquids to processing units, often constructed with simpler, open or covered rectangular or cylindrical vessels optimized for consistent flow and minimal evaporation. Your selection between a surge tank and a feed tank hinges on the need for rapid pressure control versus stable liquid storage, reflected in their distinct structural and design characteristics.

Typical Applications in Industry

Surge tanks are commonly used in industries like water treatment, oil and gas, and power generation to absorb pressure fluctuations and protect pipelines and equipment from water hammer or pressure surges. Feed tanks serve as reservoirs in chemical processing, food and beverage, and pharmaceutical industries, providing a consistent supply of raw materials or liquids to mixers, reactors, or other equipment. Understanding the distinct roles of surge tanks and feed tanks helps you optimize process stability and efficiency in industrial operations.

Advantages of Surge Tanks

Surge tanks help to absorb sudden pressure changes and water hammer effects in pipeline systems, ensuring system stability and protecting equipment from damage. They maintain consistent flow rates by storing excess fluid during peak demand and releasing it during low demand, which enhances operational efficiency. Their ability to reduce pulsations and pressure fluctuations safeguards pumps and valves, leading to extended equipment lifespan and reduced maintenance costs.

Benefits of Feed Tanks

Feed tanks provide essential benefits such as consistent fluid supply and pressure regulation, ensuring stable operation in industrial processes. They help minimize pump cavitation and equipment wear by maintaining a steady water level and reducing flow fluctuations. By using feed tanks, you improve system efficiency and prolong the lifespan of associated machinery in water treatment or boiler systems.

Installation and Maintenance Considerations

Surge tanks require installation near pressure-sensitive equipment to absorb sudden volume changes and prevent system damage, often involving robust piping and pressure monitoring instrumentation. Feed tanks are typically installed upstream of pumps or boilers, designed for easier access to enable routine cleaning and inspection to avoid contamination and ensure consistent supply. Your maintenance strategy should account for the surge tank's pressure relief systems and the feed tank's potential sediment buildup for optimal operational reliability.

Performance Impact on System Operations

Surge tanks enhance system performance by absorbing pressure fluctuations and preventing water hammer, thereby stabilizing flow and protecting equipment in high-pressure pipelines. Feed tanks primarily ensure a consistent supply of water or fluid to pumps, directly influencing operational reliability by maintaining steady flow rates and preventing cavitation. Effective integration of surge and feed tanks optimizes pressure regulation and fluid delivery, significantly improving overall system efficiency and reducing maintenance costs.

Choosing the Right Tank for Your Process

Surge tanks are designed to absorb sudden fluctuations in fluid flow or pressure, protecting pipelines and equipment from damage, while feed tanks primarily ensure a consistent supply of fluid to the process system. When choosing the right tank for your process, consider the operational demands such as pressure variations and flow stability; surge tanks are ideal for managing transient conditions, whereas feed tanks support steady input rates. Evaluating process dynamics and fluid characteristics will help match the tank type to your system's specific needs, ensuring optimal performance and equipment longevity.

Surge tank vs feed tank Infographic

libmatt.com

libmatt.com