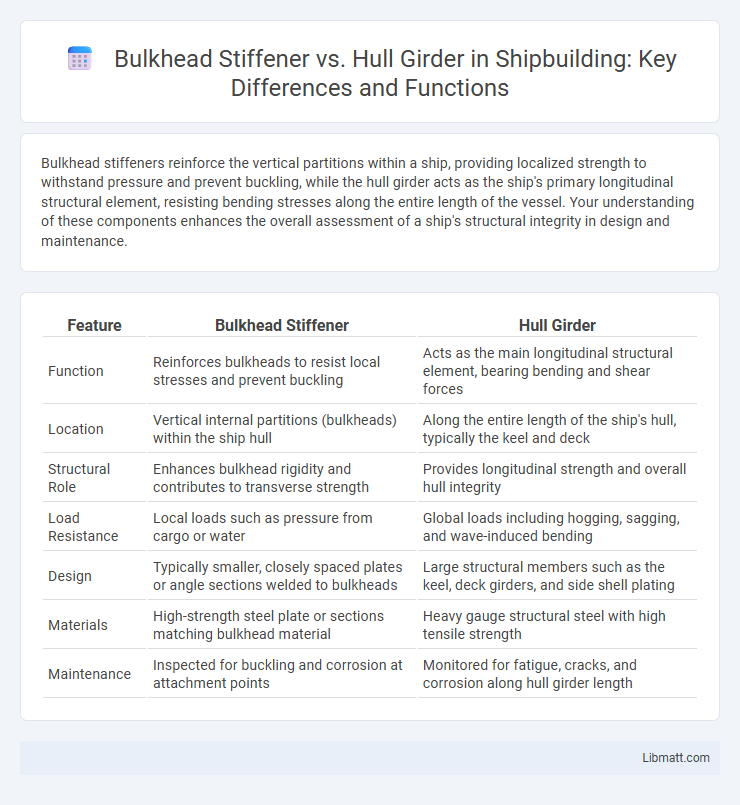

Bulkhead stiffeners reinforce the vertical partitions within a ship, providing localized strength to withstand pressure and prevent buckling, while the hull girder acts as the ship's primary longitudinal structural element, resisting bending stresses along the entire length of the vessel. Your understanding of these components enhances the overall assessment of a ship's structural integrity in design and maintenance.

Table of Comparison

| Feature | Bulkhead Stiffener | Hull Girder |

|---|---|---|

| Function | Reinforces bulkheads to resist local stresses and prevent buckling | Acts as the main longitudinal structural element, bearing bending and shear forces |

| Location | Vertical internal partitions (bulkheads) within the ship hull | Along the entire length of the ship's hull, typically the keel and deck |

| Structural Role | Enhances bulkhead rigidity and contributes to transverse strength | Provides longitudinal strength and overall hull integrity |

| Load Resistance | Local loads such as pressure from cargo or water | Global loads including hogging, sagging, and wave-induced bending |

| Design | Typically smaller, closely spaced plates or angle sections welded to bulkheads | Large structural members such as the keel, deck girders, and side shell plating |

| Materials | High-strength steel plate or sections matching bulkhead material | Heavy gauge structural steel with high tensile strength |

| Maintenance | Inspected for buckling and corrosion at attachment points | Monitored for fatigue, cracks, and corrosion along hull girder length |

Introduction to Bulkhead Stiffeners and Hull Girders

Bulkhead stiffeners are structural elements designed to reinforce bulkheads, enhancing their strength and stability against pressure and deformation in ship construction. Hull girders act as the main longitudinal structural framework, providing overall stiffness and strength to withstand bending moments and distribute loads along the vessel's length. Understanding the differences between bulkhead stiffeners and hull girders helps optimize your ship's structural integrity and performance in marine environments.

Definitions: Bulkhead Stiffener vs. Hull Girder

Bulkhead stiffeners are structural elements designed to reinforce bulkheads, providing localized strength and preventing deformation under stress in ship compartments. The hull girder refers to the ship's entire longitudinal structure that acts like a beam, supporting bending and shear forces throughout the vessel's length during navigation. While bulkhead stiffeners enhance sectional rigidity, the hull girder ensures overall structural integrity and resilience against waves, cargo loads, and hull stresses.

Structural Roles in Shipbuilding

Bulkhead stiffeners reinforce transverse bulkheads, providing localized strength to resist pressure and impact forces within the ship's compartments. Hull girders act as the primary longitudinal structural element, ensuring overall bending resistance and maintaining the ship's integrity under wave-induced stresses. Understanding the complementary roles of bulkhead stiffeners and hull girders is crucial for optimizing your ship's structural design and safety.

Materials Used for Bulkhead Stiffeners and Hull Girders

Bulkhead stiffeners are commonly made from high-strength steel or aluminum alloys to provide localized reinforcement and maintain structural integrity against deformation. Hull girders typically utilize high-tensile steel with corrosion-resistant coatings to ensure overall longitudinal strength and durability in marine environments. Selecting the appropriate materials for your bulkhead stiffeners and hull girders enhances the vessel's safety and performance in demanding sea conditions.

Design Considerations and Placement

Bulkhead stiffeners are critical for reinforcing transverse bulkheads, enhancing local strength and preventing buckling under hydrostatic pressure, while hull girders provide longitudinal strength to resist bending moments along the length of the ship. Design considerations for bulkhead stiffeners include spacing, size, and attachment to the bulkhead to ensure effective load distribution and rigidity, whereas hull girder design focuses on continuous longitudinal members like keel, deck, and stringers to maintain overall hull integrity. Proper placement of bulkhead stiffeners clustered around high-stress areas complements hull girder elements, ensuring your vessel withstands both local pressure fluctuations and global bending loads effectively.

Load Distribution and Structural Integrity

Bulkhead stiffeners concentrate load-bearing forces locally by reinforcing specific sections of the ship's structure, effectively preventing deformation and enhancing transverse strength. Hull girders distribute longitudinal stress along the vessel's entire length, maintaining overall structural integrity under bending and torsional loads. Together, these components optimize load distribution, ensuring the ship withstands dynamic sea conditions and heavy operational stresses.

Advantages of Bulkhead Stiffeners

Bulkhead stiffeners enhance the structural integrity of a ship's hull by providing localized reinforcement, which improves resistance to deformation under hydrostatic pressure. They contribute to weight efficiency by minimizing the need for heavier materials compared to hull girders, optimizing overall vessel performance. Bulkhead stiffeners also help compartmentalize the hull, increasing safety by limiting flood propagation in case of hull breaches.

Benefits of Hull Girders in Ship Design

Hull girders provide critical longitudinal strength to ships, distributing stresses from waves and cargo weight evenly along the vessel's length. Unlike bulkhead stiffeners that reinforce specific sections, hull girders enhance overall structural integrity, improving durability and resistance to bending moments and shear forces. Your ship benefits from optimized load distribution and increased safety in harsh marine environments through the effective use of hull girders.

Key Differences Between Bulkhead Stiffeners and Hull Girders

Bulkhead stiffeners are structural components that reinforce ship bulkheads, enhancing local strength and preventing buckling under pressure. The hull girder acts as the primary longitudinal strength member of the ship, resisting bending moments and distributing loads along the vessel's length. Your ship's overall structural integrity relies on the combined function of bulkhead stiffeners for localized support and the hull girder for global strength.

Conclusion: Choosing the Right Structural Element

Selecting between a bulkhead stiffener and a hull girder depends on the specific structural demands of your vessel. Bulkhead stiffeners enhance local rigidity and prevent deformation in compartment walls, while hull girders provide longitudinal strength essential for overall hull integrity. Prioritizing the right element ensures optimal safety, performance, and durability of the ship's structure.

Bulkhead stiffener vs hull girder Infographic

libmatt.com

libmatt.com