Ballast tank coatings are specifically designed to withstand harsh marine environments and prevent corrosion caused by saltwater exposure, while cargo tank coatings focus on resisting chemical damage and ensuring product compatibility based on the type of cargo transported. Choosing the right coating for your vessel enhances durability and operational safety by matching the coating properties to the specific tank environment.

Table of Comparison

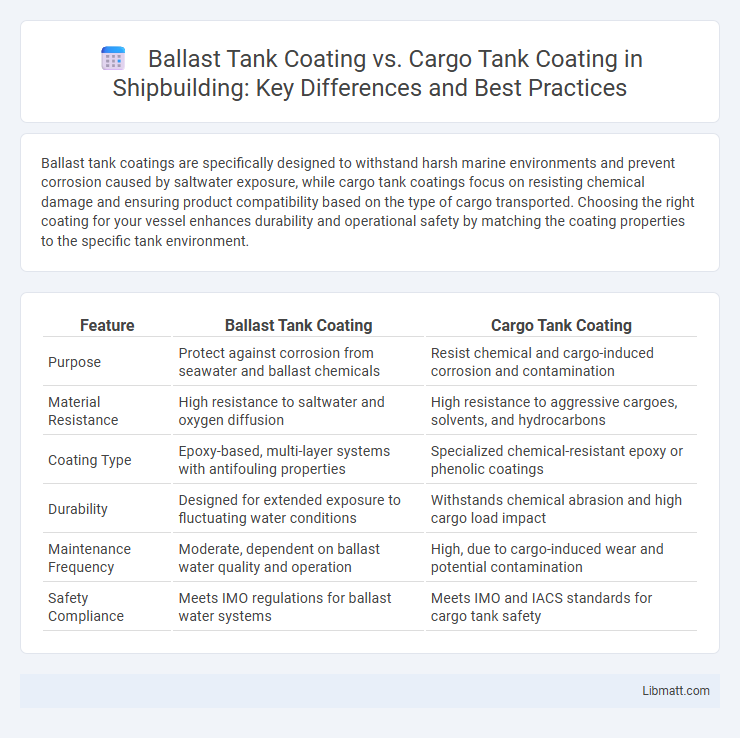

| Feature | Ballast Tank Coating | Cargo Tank Coating |

|---|---|---|

| Purpose | Protect against corrosion from seawater and ballast chemicals | Resist chemical and cargo-induced corrosion and contamination |

| Material Resistance | High resistance to saltwater and oxygen diffusion | High resistance to aggressive cargoes, solvents, and hydrocarbons |

| Coating Type | Epoxy-based, multi-layer systems with antifouling properties | Specialized chemical-resistant epoxy or phenolic coatings |

| Durability | Designed for extended exposure to fluctuating water conditions | Withstands chemical abrasion and high cargo load impact |

| Maintenance Frequency | Moderate, dependent on ballast water quality and operation | High, due to cargo-induced wear and potential contamination |

| Safety Compliance | Meets IMO regulations for ballast water systems | Meets IMO and IACS standards for cargo tank safety |

Introduction to Ballast Tank and Cargo Tank Coatings

Ballast tank coatings are specifically designed to protect steel surfaces from corrosion caused by constant exposure to seawater and varying chemical compositions within ballast tanks. Cargo tank coatings prioritize chemical resistance and durability to safely contain and isolate a wide range of liquid cargoes, including crude oil, chemicals, and liquefied gases. Both coatings incorporate advanced anti-corrosive properties but differ in their formulation to address distinct environmental challenges and operational requirements.

Purpose and Functions of Ballast Tank Coating

Ballast tank coatings are specifically designed to protect the internal surfaces of ballast tanks from corrosion caused by constant exposure to seawater and fluctuating oxygen levels. These coatings provide chemical resistance to sulfides and other aggressive substances, ensuring the structural integrity and longevity of the tank. Your choice in ballast tank coatings directly impacts the vessel's maintenance costs and operational safety by preventing leaks and contamination.

Purpose and Functions of Cargo Tank Coating

Cargo tank coating is specifically designed to protect the tank's interior surfaces from corrosion caused by the chemicals or cargoes transported, ensuring the structural integrity and longevity of the tank. It provides a non-reactive barrier that prevents contamination and maintains cargo purity while resisting aggressive chemicals, temperature fluctuations, and mechanical wear. Your choice of cargo tank coating directly impacts operational safety, maintenance costs, and regulatory compliance in chemical and oil transportation.

Key Differences Between Ballast and Cargo Tank Environments

Ballast tank coatings must resist highly corrosive seawater, sulfates, and oxygen-depleted conditions, while cargo tank coatings are designed to withstand chemical exposure and product compatibility with oils, chemicals, or gases. Ballast tanks experience frequent water ingress and microbiological activity causing microbial-induced corrosion, whereas cargo tanks face challenges related to chemical resistance, temperature fluctuations, and product contamination. The coating systems for ballast tanks emphasize enhanced corrosion protection and flexibility, while cargo tank coatings prioritize chemical resistance and surface smoothness for easy cleaning and product purity.

Chemical and Physical Properties of Coatings

Ballast tank coatings require high resistance to corrosion and chemical degradation due to constant exposure to seawater and contaminants, emphasizing strong adhesion, flexibility, and impermeability to protect the vessel's structural integrity. Cargo tank coatings prioritize chemical resistance to specific transported substances, including petroleum products or liquefied gases, ensuring compatibility and preventing permeation or reaction with cargo chemicals. Your choice of coating must consider these distinct chemical and physical properties to ensure optimal durability and performance in either ballast or cargo tank environments.

Types of Coatings Used for Ballast vs Cargo Tanks

Ballast tank coatings typically require high-performance epoxy or polyurethane systems designed to resist corrosion and prevent seawater contamination, while cargo tank coatings depend on the specific cargo type, often using chemical-resistant epoxies or phenolic coatings to withstand harsh chemicals or oil products. Ballast tank coatings prioritize durability in a high-moisture environment, with anti-corrosive properties tailored for constant water exposure, whereas cargo tank coatings focus on maintaining chemical integrity and preventing cargo contamination. Your choice of coating should align with the tank's function and environmental conditions to ensure optimal protection and longevity.

Corrosion Protection Requirements

Ballast tank coating requires highly durable corrosion protection designed to withstand exposure to seawater and prevent structural degradation in harsh marine environments. Cargo tank coatings demand specialized chemical-resistant materials that protect against aggressive cargoes like crude oil and chemicals, ensuring minimal contamination and corrosion. Both coatings must meet stringent International Maritime Organization (IMO) and ISO standards to guarantee long-term asset integrity and safety.

Regulatory Standards and Compliance

Ballast tank coating and cargo tank coating differ significantly in regulatory standards and compliance requirements, as ballast tanks demand coatings resistant to corrosion from seawater and comply with IMO PSPC (International Maritime Organization Performance Standard for Protective Coatings). Cargo tank coatings, however, must meet stringent safety and chemical resistance standards such as those outlined by the International Maritime Organization's IGC Code for liquefied gas carriers or IMO MARPOL regulations for oil tankers. Your selection of coating must align with these specific standards to ensure vessel integrity, environmental protection, and adherence to international maritime regulations.

Maintenance and Inspection Practices

Ballast tank coatings require frequent maintenance and rigorous inspection due to constant exposure to seawater and corrosive elements, often involving traditional abrasive cleaning and spot repairs to prevent corrosion. Cargo tank coatings, especially in chemical or oil carriers, demand specialized inspection protocols to ensure coating integrity against aggressive cargoes, with maintenance focusing on minimizing contamination and maintaining certification standards. Your choice of coating impacts the frequency and complexity of upkeep, making it essential to select a system aligned with the vessel's operational profile and inspection schedule.

Cost Considerations and Long-Term Performance

Ballast tank coating generally requires higher initial investment due to the need for enhanced corrosion resistance against seawater exposure, whereas cargo tank coating prioritizes chemical resistance depending on the type of cargo, often influencing cost variability. Long-term performance in ballast tanks depends on abrasion resistance and maintenance frequency, while cargo tank coatings demand durability against chemical reactions and temperature fluctuations to minimize downtime and repair costs. Understanding your vessel's operational profile ensures selecting the optimal coating that balances cost efficiency with prolonged protective performance.

Ballast tank coating vs cargo tank coating Infographic

libmatt.com

libmatt.com